Temperature difference engine

A temperature difference engine, ambient temperature technology, applied in machines/engines, mechanical equipment, mechanisms that generate mechanical power, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

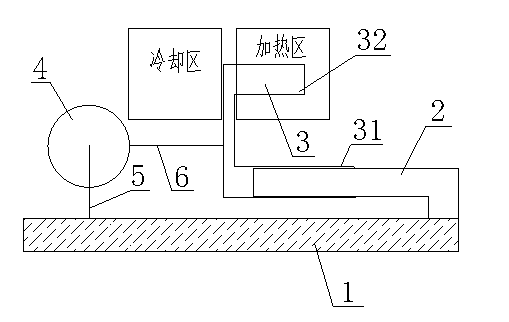

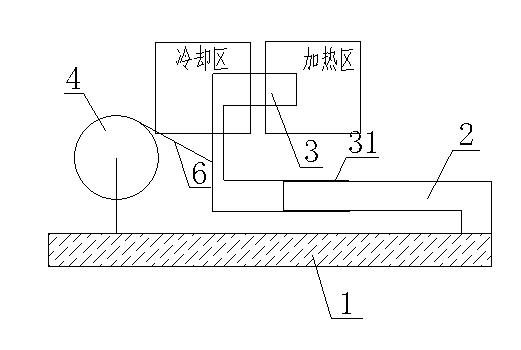

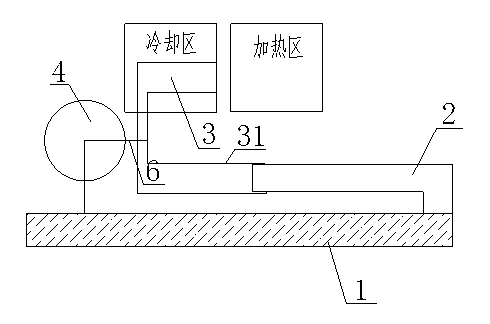

[0021] This embodiment provides a temperature difference engine, such as Figure 1 to Figure 4 As shown, they are schematic diagrams of four working states of the temperature difference engine of the present embodiment:

[0022] The thermoelectric engine includes a movable cylinder 3 filled with gas (which includes two parts of an air cavity body 32 and a cylinder 31), a fixed piston 2, a flywheel 4 as an energy transmission and conversion device, and is used to fix the fixed piston 2. And the fixed base 1 of the flywheel 4, and the heating zone and cooling zone placed at the two ends of the moving cylinder 3.

[0023] The air cavity body 32 is a heating and cooling induction area. The inner wall of the cylinder 31 is connected with the fixed piston 2. The fixed piston 2 can move in the cylinder 31 and seal the movable cylinder 3. The heating zone and the cooling zone are respectively located at two ends of the movement range of the air chamber body 32 . The rotating shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com