Intelligent automatic cladding production line of strip-shaped insulation materials

A technology of insulating materials and production lines, applied in the direction of conductor/cable insulation, etc., to achieve the effect of solving frequent belt breaks, fast line speed, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

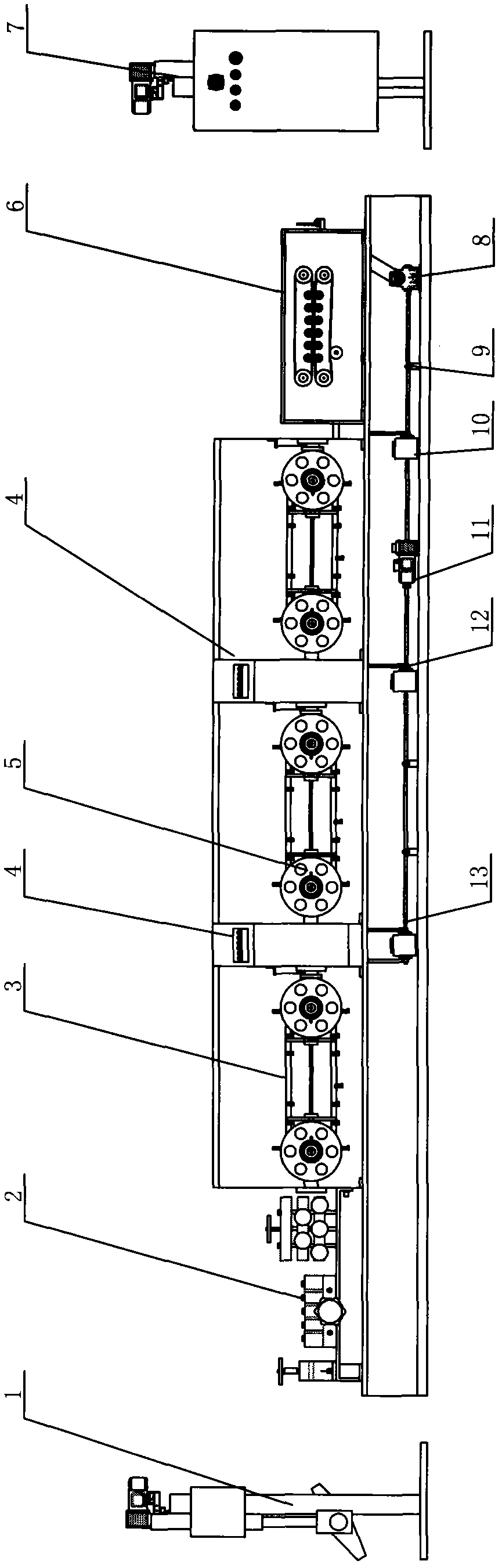

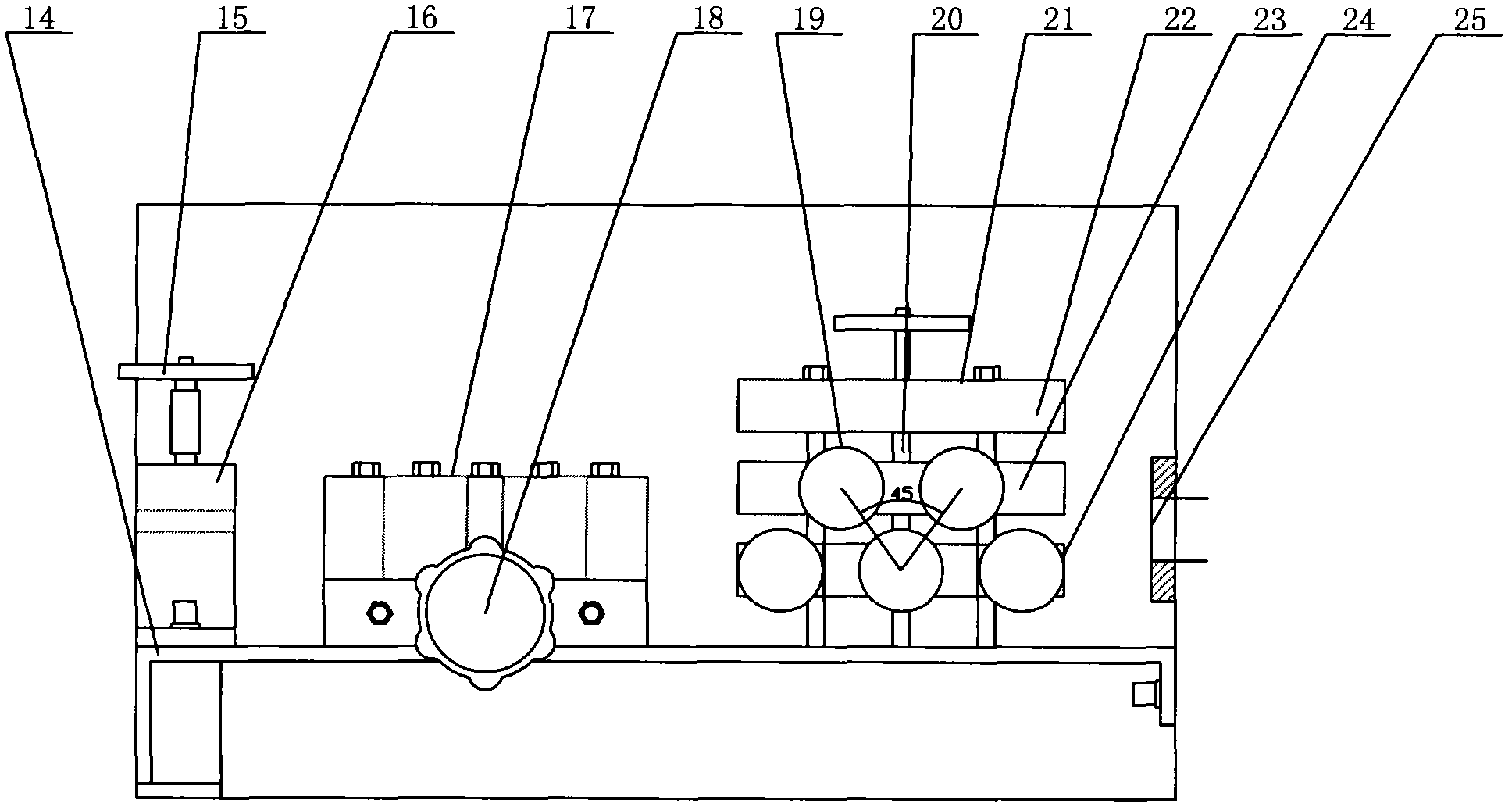

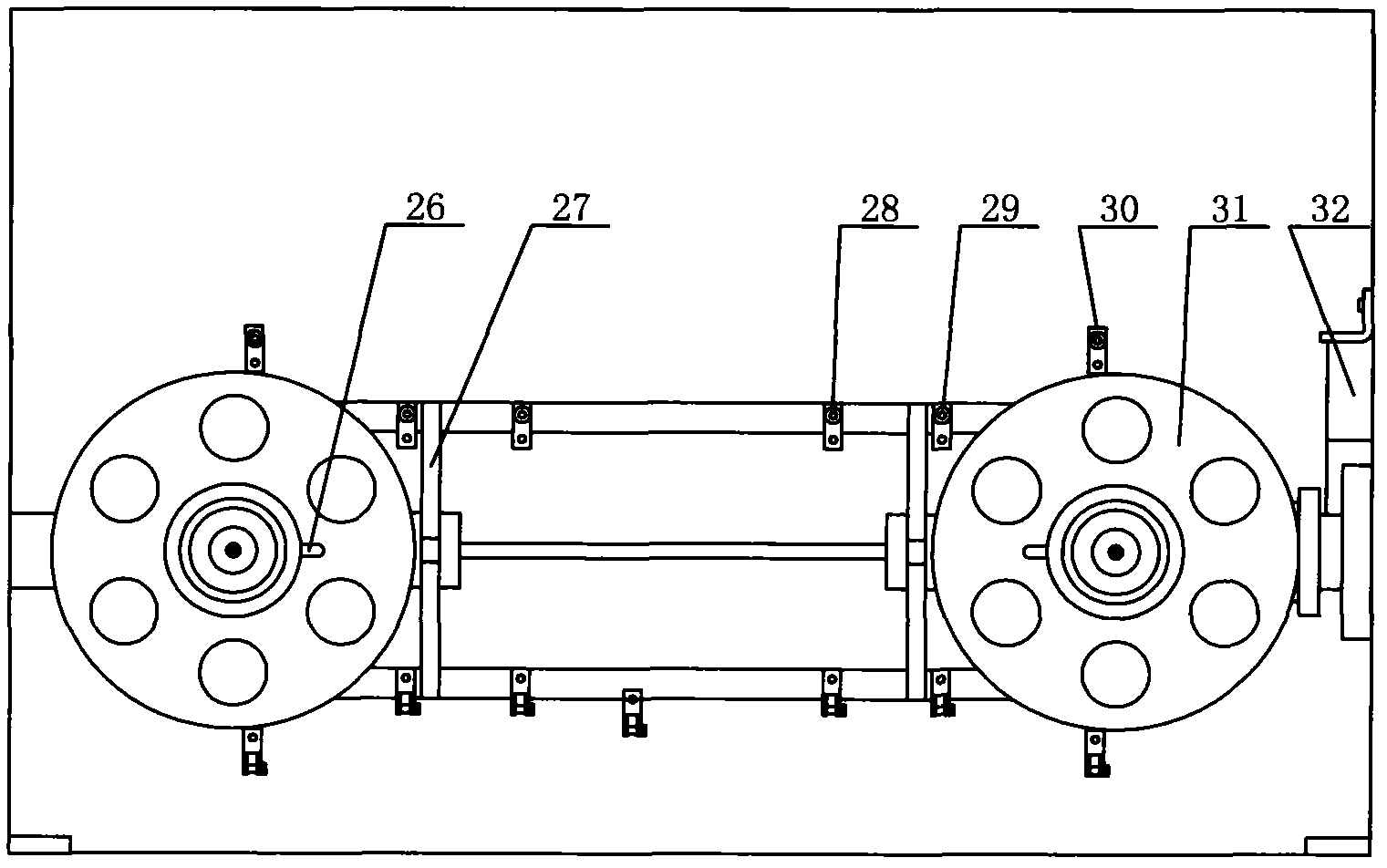

[0025] exist figure 1 Middle: The front of the production line is equipped with a fixed gantry tension wire release mechanism 1; the middle is continuously equipped with a conductor wire straightening mechanism 2, three belt-shaped insulating material tangential rotation coating mechanisms 3, and an anti-slip synchronous crawler type wire pulling mechanism 6. The outlet hole 25 of the mechanism is on the same horizontal straight line and kept centered. The belt-shaped insulating material tangentially rotates and covers the mechanism 3. There is a buckle ratchet anti-retraction and anti-loosening chuck mechanism 5. Each belt-shaped insulating material A control box 4 is arranged between the tangential rotation covering mechanism 3, and the main rotating seat plate 36 on each belt-shaped insulating material tangential rotation covering mechanism 3 is connected with the gear on the gear box 10 through a belt, and the servo motor 11 drives the transmission. The shaft 12 runs, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com