Method and device for vacuum impregnation and vacuum predrying of nuclear grade active carbon

A technology of vacuum impregnation and treatment methods, applied in lighting and heating equipment, chemical instruments and methods, drying solid materials, etc., to achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described below with reference to the drawings and specific embodiments.

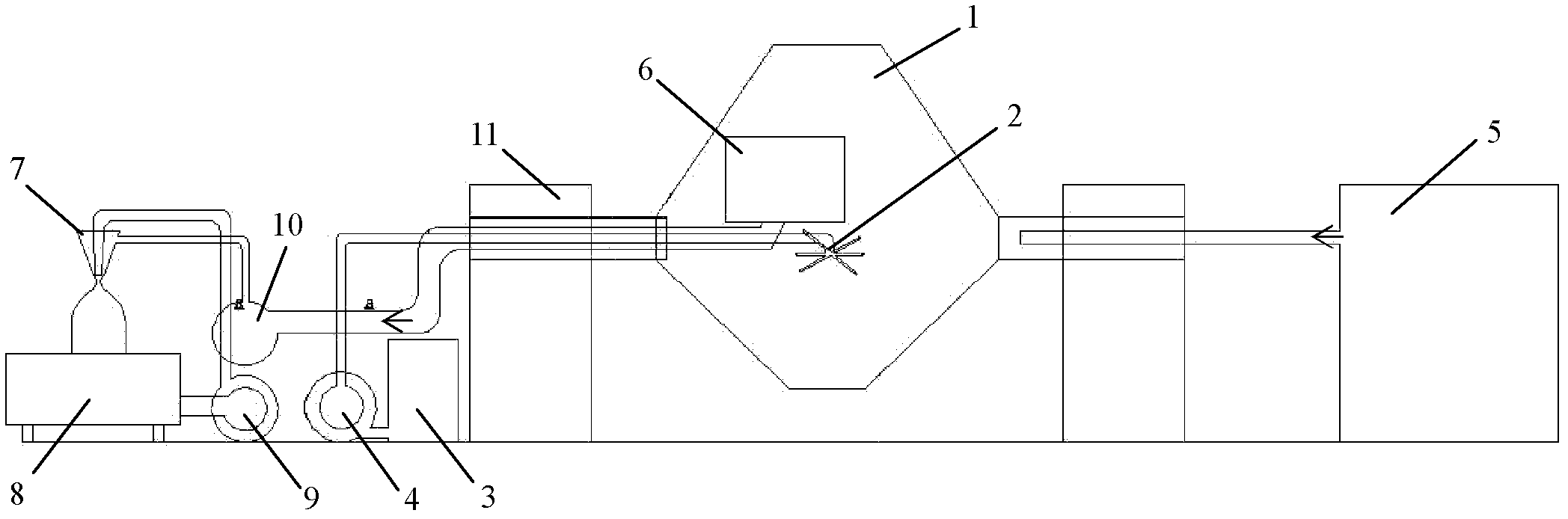

[0016] Such as figure 1 As shown, the nuclear-grade activated carbon vacuum impregnation and pre-drying treatment equipment provided by the present invention includes a rotatable and rolling vacuum tank 1. The vacuum tank 1 is provided with a spray head 2, which is connected to the dispensing system through a pipeline, The vacuum tank 1 is also connected to a heating system. The vacuum tank 1 has a double-cone structure, the wall of the vacuum tank 1 is provided with an interlayer, and the interlayer is connected to the heating boiler 5 of the heating system through a pipeline. The dispensing system includes a dispensing box 3 and a water pump 4 connected thereto. The immersion liquid in the dispensing box 3 is introduced into the pipeline through the water pump and sprayed out through the spray head 2. A filter screen 6 is provided in the vacuum tank 1, and the vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com