Method and device for extracting oil from kitchen garbage

A technology of kitchen waste and extraction method, which is applied in the field of oil recovery of oily wastes, and achieves the effects of high work efficiency, reduced use of raw material steam, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

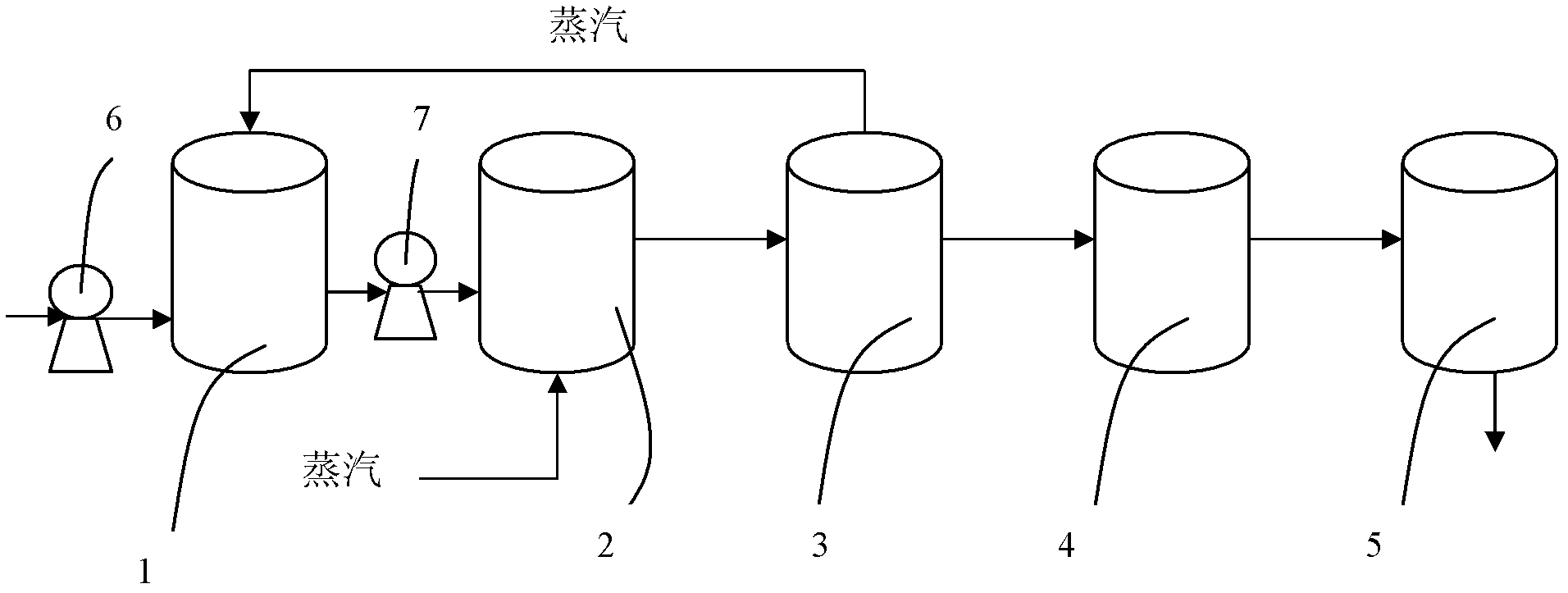

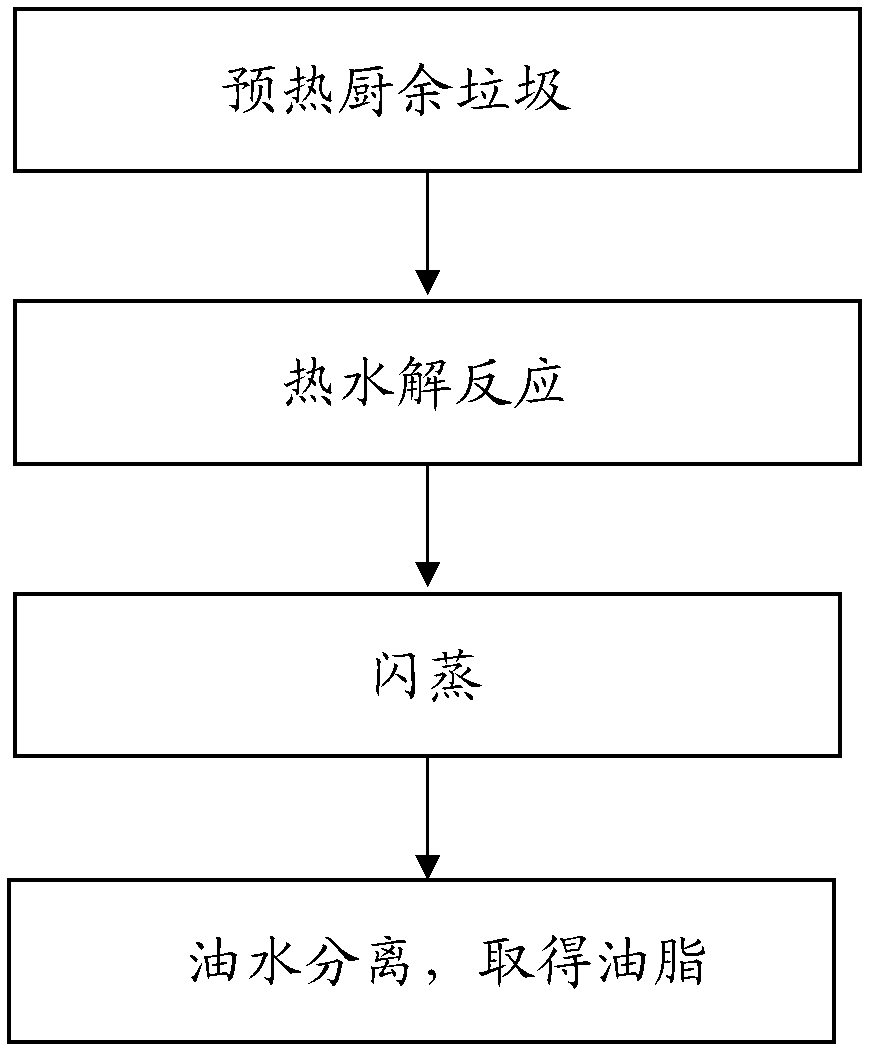

[0038] Example 1. Kitchen waste with a water content of 88.1% and a total oil content of 123.4mL / kg is transported to the preheating tank through a paste pump, mixed with flash steam and preheated to 60°C, 0MPaG, and the residence time is 30min; The water heating feed pump pumps the preheated material into the water heating tank, and heats it to 140°C with raw material steam, 0.4MPaG, and the reaction time is 10 minutes; after the reaction, the kitchen waste enters the flash tank to lower the temperature and pressure, and the temperature of the flash tank The temperature is 80°C, the pressure is 0 MPaG, and the residence time is 10 minutes; the kitchen waste slurry after flashing flows to the oil-water separator by itself for oil-water separation; the obtained oil is stored in the oil storage tank.

[0039] As a result of the reaction, the floatable oil content of the kitchen waste slurry was 38.1 mL / kg, and the oil recovery rate was 30.9%.

Embodiment 2

[0040] Embodiment 2, keeping the reaction time of the hydrothermal tank continued for 30min, and other reaction conditions were the same as in Embodiment 1. As a result of the reaction, the floatable oil content of the kitchen waste slurry was 44.3mL / kg, and the oil recovery rate was 35.9%.

Embodiment 3

[0041] Embodiment 3, keep the hydrothermal tank reaction time to continue 50min, other reaction conditions are the same as embodiment 1. As a result of the reaction, the floatable oil content of the kitchen waste slurry was 45.9 mL / kg, and the oil recovery rate was 37.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com