Portable rechargeable electric welding machine

An electric welding machine and portable technology, which is applied in the field of portable rechargeable electric welding machines, can solve the problems of long distance between the electric welding machine and electric welding, high safety factor, threats to personal safety, etc., and achieve the goal of preventing danger, high safety, and stable output current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

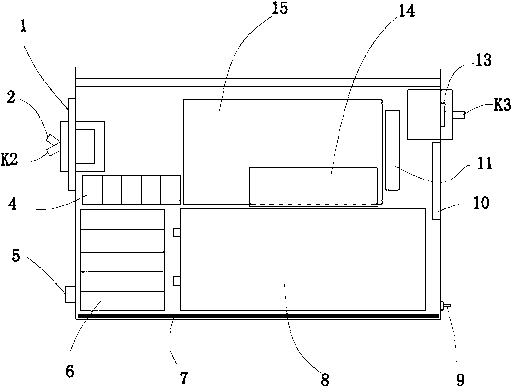

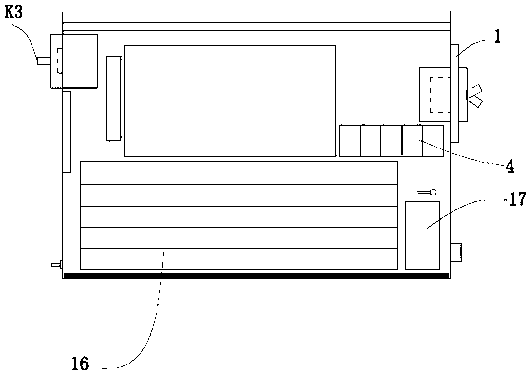

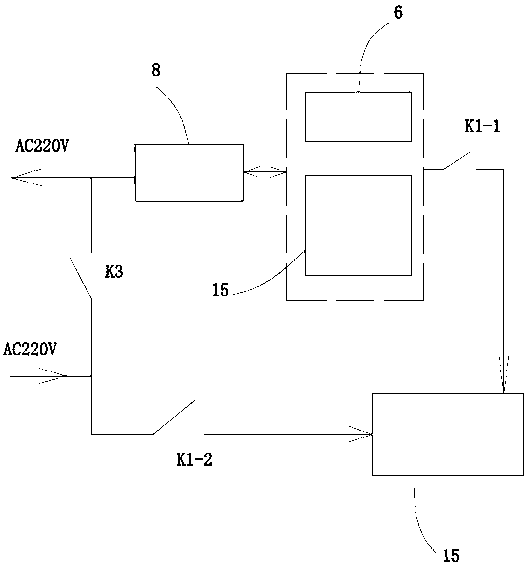

[0035] Embodiment: a kind of portable rechargeable electric welding machine (see attached figure 1 attached figure 2 attached image 3 ), including the shell, the epoxy plate 7 is fixed on the bottom of the shell, the AC output terminal 1, the welding machine power switch 2, and the power control switch K2 are fixed on one side of the shell, and the lower part of the side is provided with a welding torch outlet 5. A housing cooling fan 10 , a charging switch K3 and a charging socket 13 are fixed on the side of the other end of the housing, and a grounding protection terminal 9 is provided on the lower part of the side. 6 sets of batteries are fixed inside the casing to form 5 sets of batteries 16 as a welding DC power supply and the 6th set of batteries 6 as a power output, and the 6 sets of batteries are connected with a bidirectional inverter power supply board 8 . The housing is provided with a relay group 14 and a welding module 15, and an internal cooling fan 11 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com