Method recovering ammonia gas in exhaust gas containing organic metal or dust

An organometallic and exhaust gas technology, applied in the preparation/separation of ammonia, energy input, etc., can solve environmental impact and other problems, and achieve the effect of reducing blockage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

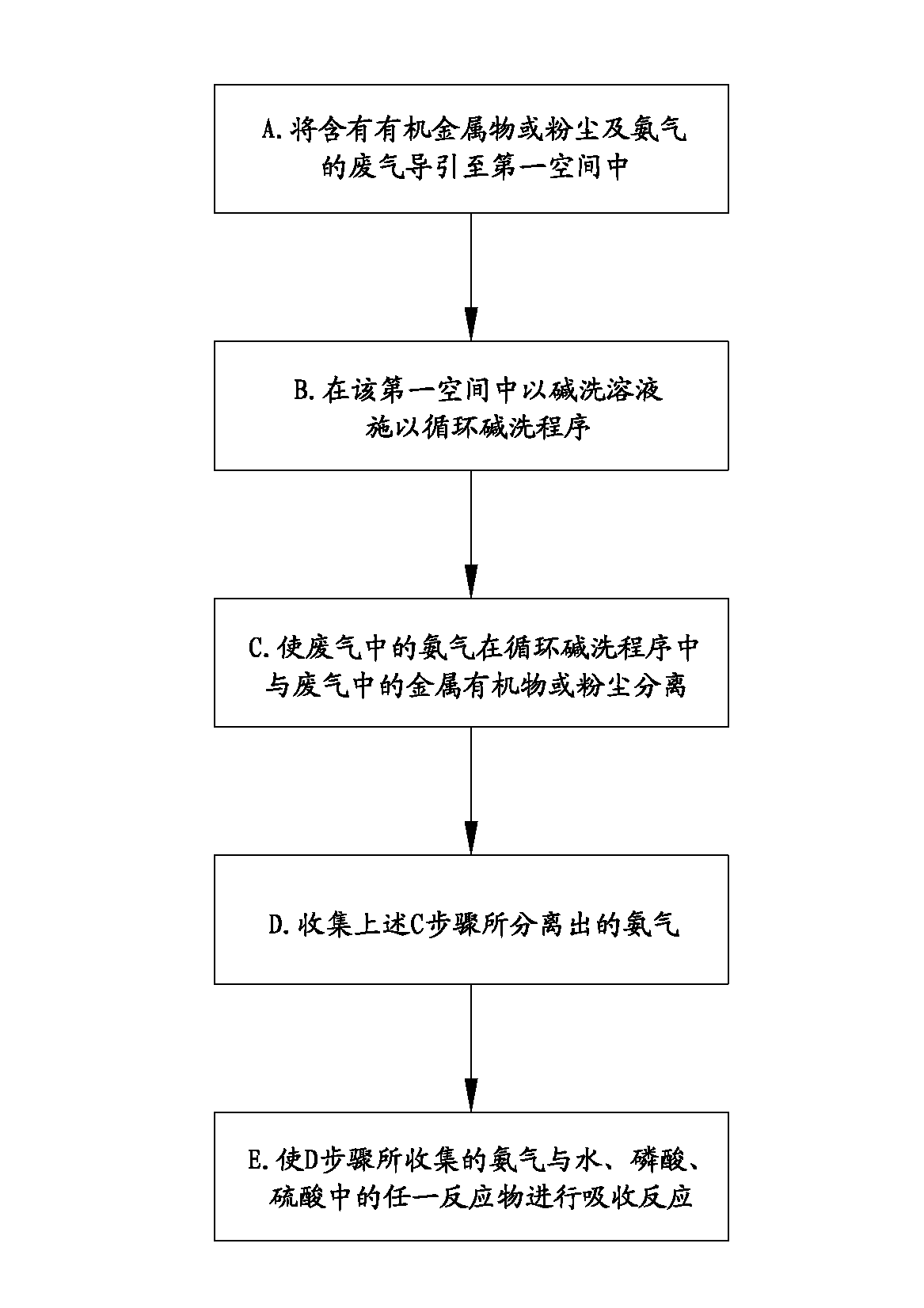

[0047] see figure 1 , which is a flowchart of an embodiment of the method for recovering ammonia in waste gas containing organometallic or dust of the present invention; the method for recovering ammonia in waste gas containing organometallic or dust of the present invention comprises the following steps:

[0048] A. Introduce waste gas containing organic metals or dust and ammonia into the first space;

[0049] B. In the first space, apply a cyclic alkali washing procedure with the alkali washing solution;

[0050] C. Separating the ammonia in the exhaust gas from the organic metal or dust in the exhaust gas during the cyclic alkali washing process;

[0051] D. collect the separated ammonia of above-mentioned C step;

[0052] E. Make the ammonia collected in step D and any reactant in water, phosphoric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com