Entropy circulating engine

A technology of engines and compressors, applied in engine components, machines/engines, closed gas positive displacement engine factories, etc., can solve problems affecting power and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

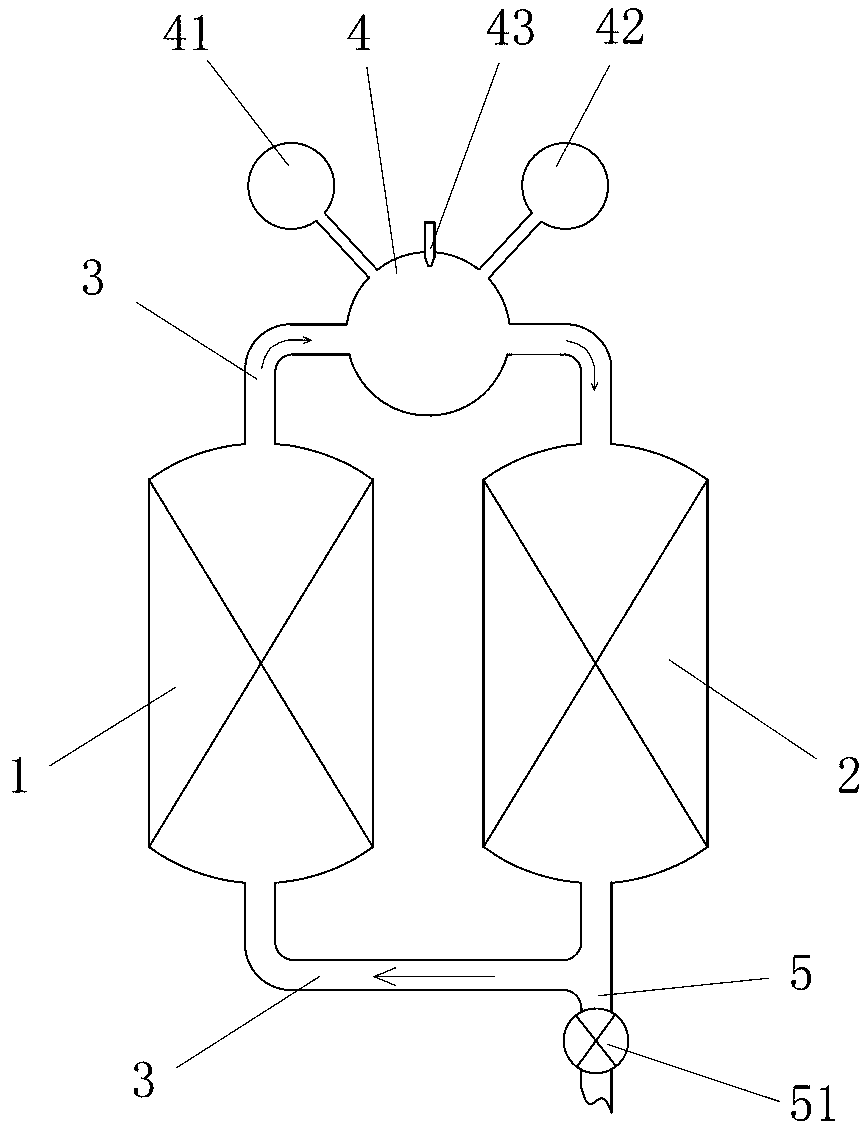

[0153] like figure 1 The entropy cycle engine shown includes a gas compression mechanism 1, a gas work mechanism 2 and two communication passages 3, and the working medium outlet of the gas compression mechanism 1 performs work with the gas through one communication passage 3 along the flow direction of the working medium. The working medium inlet of the mechanism 2 is connected, and the working medium outlet of the gas working mechanism 2 is connected with the working medium inlet of the gas compression mechanism 1 through another communication channel 3 along the flow direction of the working medium, that is, the gas compression mechanism 1 and the gas working mechanism 2 are connected through the two communicating passages 3 to form a working medium closed circuit; an internal combustion combustion chamber 4 is provided in the working medium closed circuit, and a working medium is provided on the working medium closed circuit. Outlet 5; at least one of the gas compression ...

Embodiment 2

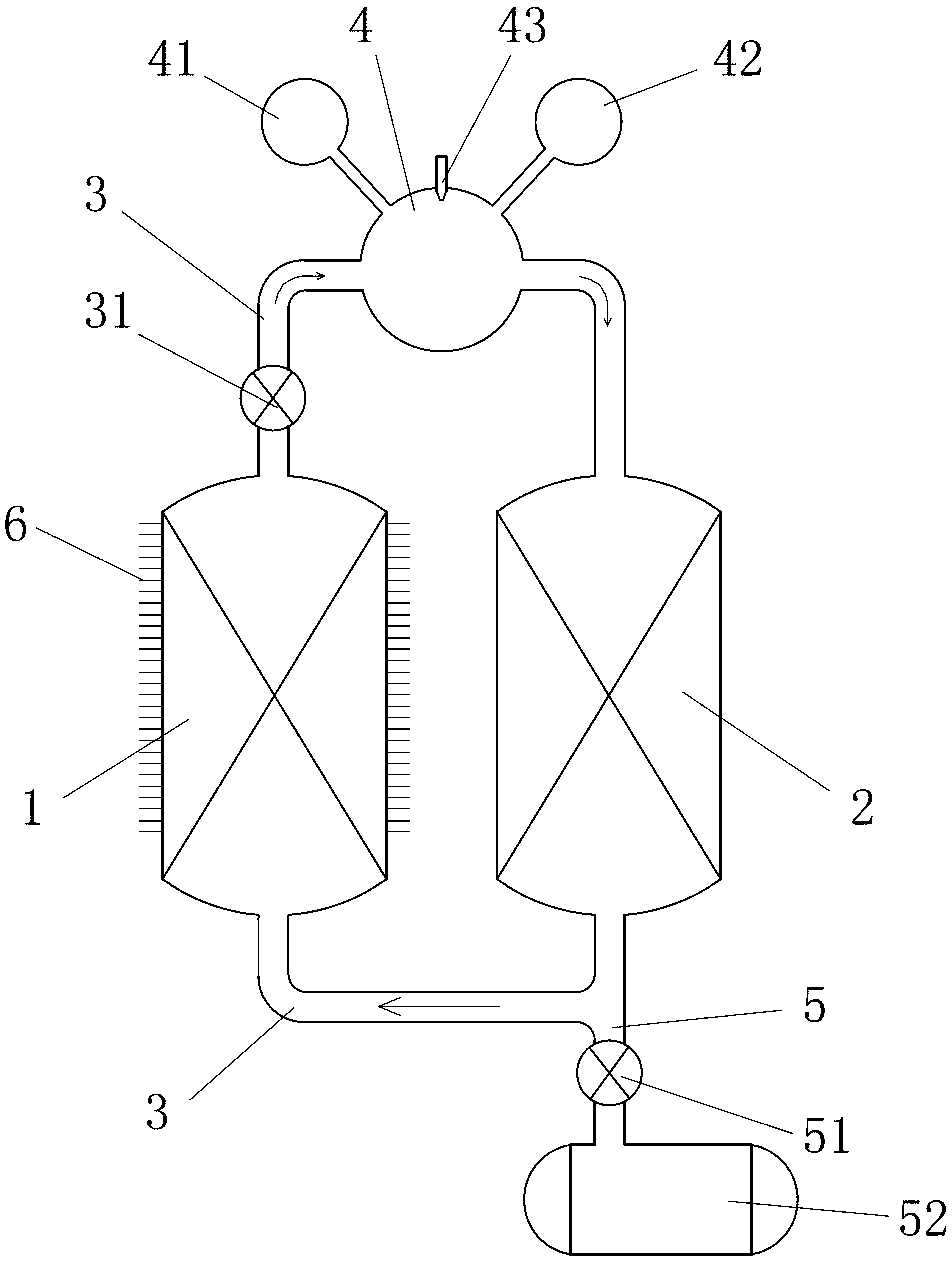

[0158] like figure 2 The entropy cycle engine shown differs from Embodiment 1 in that: the entropy cycle engine also includes a cooler 6, the cooler 6 is arranged on the gas compression mechanism 1, and the gas compression mechanism 1 A check valve 31 is provided on the communication passage 3 between the working medium outlet of the internal combustion chamber 4 and the working medium inlet of the internal combustion chamber 4 .

[0159] The working fluid outlet 5 is connected with an air storage tank 52. When the pressure of the working fluid closed circuit is higher than the set limit, the pressure of the working medium closed circuit is set to be at least greater than 2MPa; the control valve 51 can be As a pressure control valve, part of the working medium that causes excessive pressure is introduced into the gas storage tank 52, which can be used as a high-pressure gas source.

[0160] Optionally, the pressure bearing capacity of the closed circuit of the working fluid ...

Embodiment 3

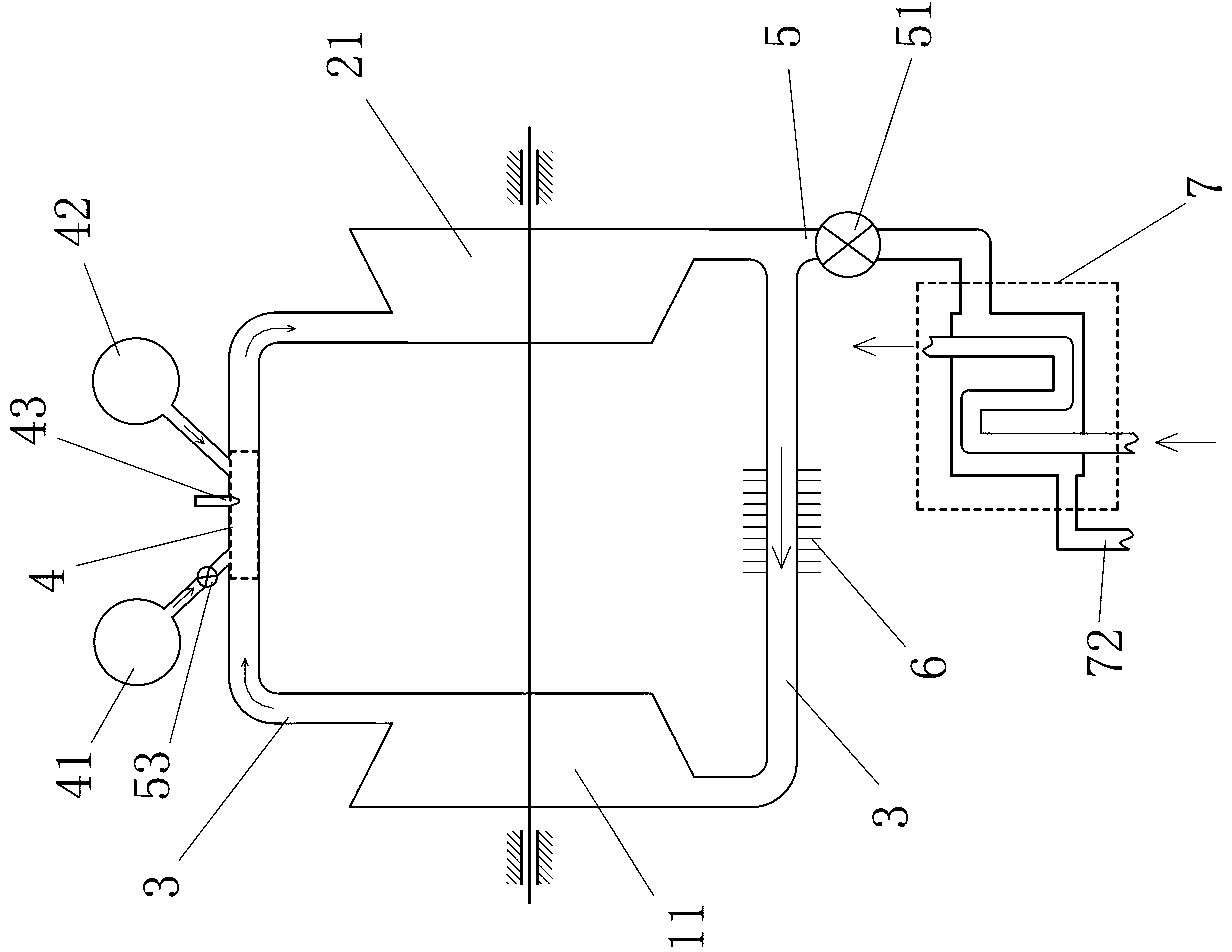

[0164] like image 3 Shown entropy cycle engine, its difference with embodiment 2 is: described gas compression mechanism 1 is set as impeller compressor 11, and described gas working mechanism 2 is set as turbine power mechanism 21; Described internal combustion combustion chamber 4 is arranged at In the communication passage 3 between the working medium outlet of the impeller compressor 11 and the turbine power mechanism 21 , the oxidant source 41 is directly communicated with the internal combustion chamber 4 through an oxidant control valve 53 .

[0165] The working fluid export port 5 communicates with the cooled fluid channel of the non-direct mixing condensing cooler 7, that is, the exported excess working fluid will be condensed and cooled, thereby reducing the emission pollution to the environment.

[0166] Optionally, two impeller compressors 11 are arranged in series to realize multi-stage compression; the turbine power mechanism 21 can also be set to two to realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com