High-frequency multi-pulse detonation initiation igniter

A multi-pulse and igniter technology, which is used in blasting cylinders, weapon accessories, offensive equipment, etc., can solve the problems of easy damage of ignition and detonation devices and unsuitable occasions for detonation and detonation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

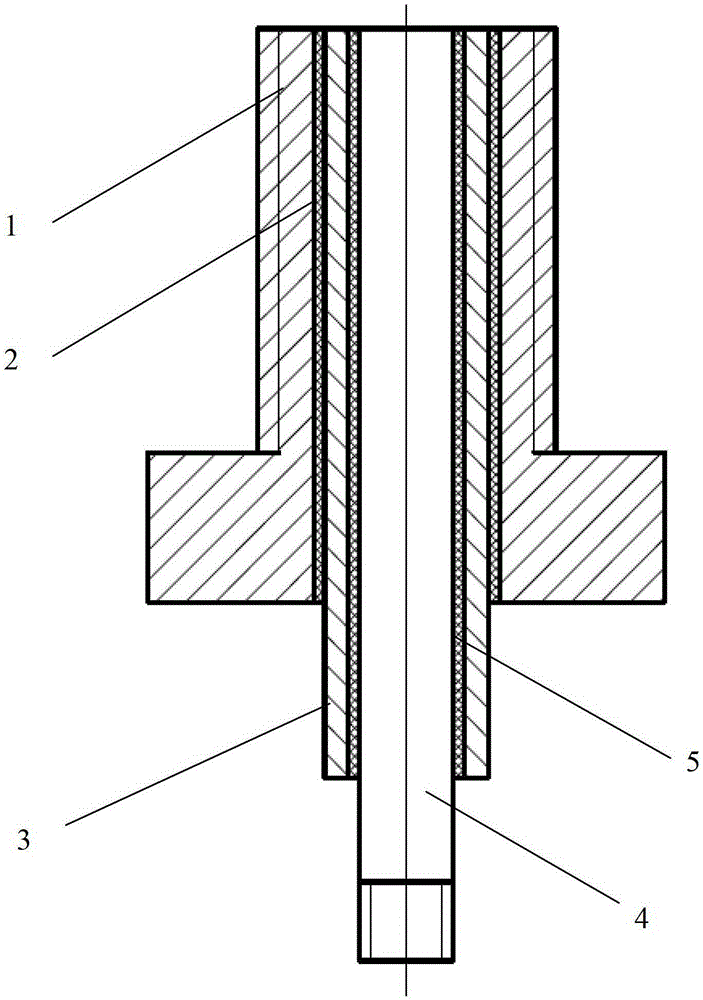

[0019] Such as figure 1 As shown, the igniter of the present invention is a coaxial structure. The outermost layer is a stainless steel sleeve 1, which is used as a discharge negative electrode and connected with the structure of the igniter application occasion. The innermost layer is a copper column 4 made of brass, which is used as the positive discharge electrode, and a thicker ceramic cylinder 3 is used for insulation and isolation between the positive discharge electrode and the negative discharge electrode. The high temperature resistant epoxy resin 5 is used for bonding between the discharge positive electrode and the ceramic cylinder; the high temperature resistant epoxy resin 2 is used for bonding between the discharge negative electrode and the insulating ceramic cylinder 3 . In the embodiment of the present invention, the thickness of the ceramic cylinder 3 is preferably 1-1.5 mm, and the length is preferably 25 mm. The length of the copper column is preferably 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com