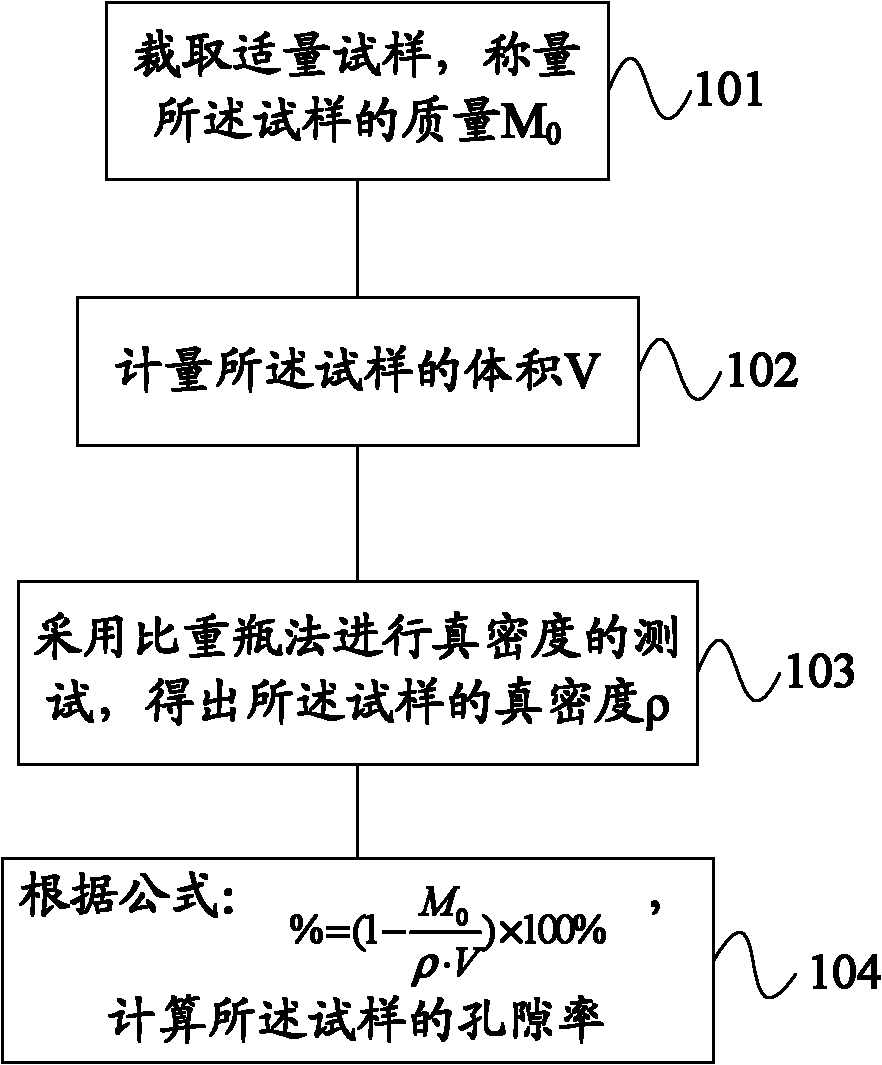

Method of testing porosity

A technology of porosity and pycnometer method, which is applied in the direction of measuring device, specific gravity measurement, permeability/surface area analysis, etc., can solve the problems of expensive instruments and consumables, cumbersome testing process, high cost of testing process, etc. and the effect of cheap consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

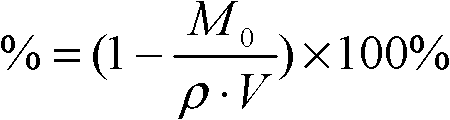

Method used

Image

Examples

Embodiment Construction

[0024] For the sake of reference and clarity, the descriptions, abbreviations or abbreviations of technical terms used in the following are summarized as follows:

[0025] True density: refers to the actual volume of the solid substance in the volume of the material in an absolutely dense state, excluding internal voids.

[0026] Porosity: The ratio of the volume of measurable pores and pores (pore volume and pore volume) to the total volume occupied in a certain amount of solid.

[0027] Diaphragm: Commonly used diaphragm materials for batteries include porous membranes of fiber paper or non-woven fabric and synthetic resin. Common diaphragms include porous membranes of polypropylene and polyethylene.

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com