Steel production energy consumption immune prediction control model

A predictive control and predictive model technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of incomplete cost, unscientific construction of cost index system, and difficulty in accurately predicting dynamic problems of steel energy consumption, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

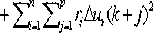

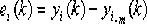

[0049] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , an immune predictive controller structure of an immune predictive control model for energy consumption in iron and steel production, an antibody code for an immune predictive control model for energy consumption in iron and steel production, a layered system energy structure analysis of an immune predictive control model for energy consumption in iron and steel production, and a steel production Production energy consumption immune predictive control model energy consumption cost index quantification model, a steel production energy consumption immune predictive control model energy consumption cost predictive control model, firstly analyze the energy transfer and digestion mechanism of each process link in the production process, and establish the overall process-local The layered system of process-process flow is often used in the energy density decomposition model of macroscopic energy consumption anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com