An Optimal Design Method for Engine Cooling System

An engine cooling and cooling system technology, applied in computing, special data processing applications, instruments, etc., can solve the problems of unrealizable modification, passive optimization of work, limited layout space, etc., to improve development efficiency, complete data, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

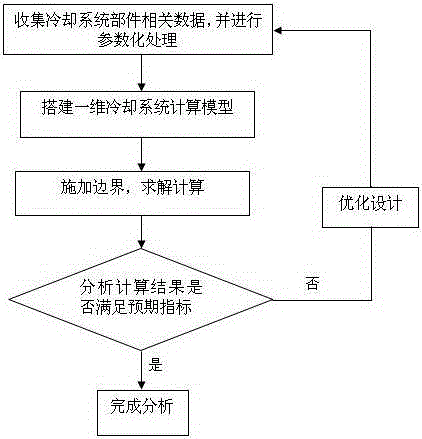

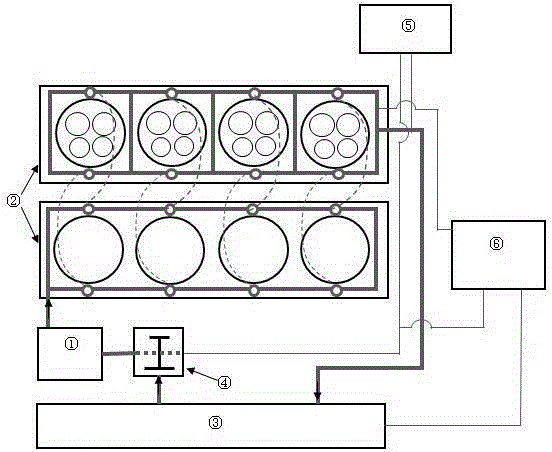

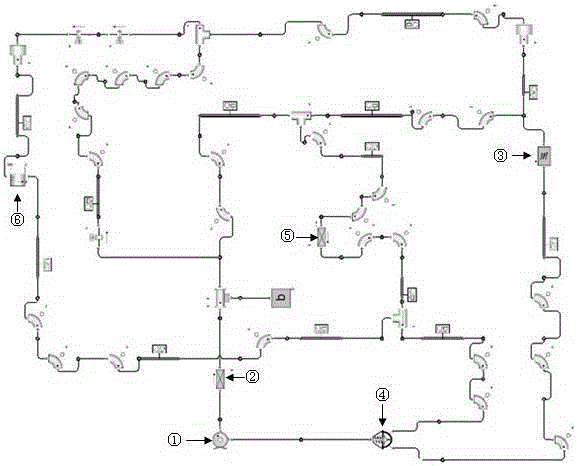

Method used

Image

Examples

Embodiment 1

[0032]One of the expected design goals of the engine cooling system in one embodiment is that when the rated operating point of the water pump is the engine speed of 6000rpm, the water pump flow rate of 119l / min and the pressure rise of 120KPa will be satisfied, while another design goal is the engine speed of 2000rpm (idle speed Working condition), the flow rate of the warm air core should meet 8.9l / min. Bring the relevant data parameters of each component of the above engine cooling system into the above simulation model for simulation calculation, and combine the various working conditions (speed, etc.) to obtain the calculation results of the flow, temperature and pressure distribution of each component as shown in the table below:

[0033]

[0034] It can be seen that when the engine speed is 6000rpm, the flow rate of the water pump meets the requirements, but the calculated pressure rise of the water pump is 156.8KPa, which is higher than the target requirement of 120K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com