Closed cooling tower checking method based on hot water cooling

A closed cooling tower and hot water cooling technology is applied in the field of check calculation to achieve the effects of saving operating costs, reducing production costs and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

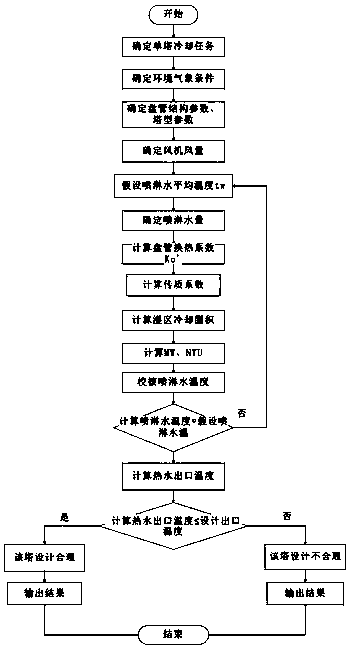

Method used

Image

Examples

Embodiment 1

[0063] Determine the working condition of the closed tower: single tower cooling water flow Q=25m 3 / h, hot water inlet temperature T 1 =42℃, outlet temperature T 2 =32°C,

[0064] Determine the meteorological conditions: dry bulb temperature θ=31°C, wet bulb temperature τ=27.5°C, atmospheric pressure Pa=101.325kPa, calculate relative humidity φ i 0.765, the moisture content of the air entering the tower x i 0.02182kg / kg(DA), dry bulb temperature corresponds to saturated steam partial pressure p θ 4.49kPa, wet bulb temperature corresponds to saturated steam partial pressure p τ 3.6698kPa, the density of wet air entering the tower ρ i 1.1487kg / m 3 , the enthalpy value of air entering the tower h i 86.968kJ / kg.

[0065] Determine coil structure parameters and tower type parameters: material: galvanized steel pipe, elliptical tube specification: 31.8×21.6×1.5mm, tube length 2.58m, 2 layers of tubes per pass, 41 tubes per pass, 10 rows in total, heat exchange area 89.8m2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com