Regeneration water factory effluent residual chorine risk prediction method

A technology of risk prediction and residual chlorine, applied in prediction, general water supply conservation, instruments, etc., can solve problems such as high content and types of pollutants, increased microbial indicators in water, increased generation of disinfection by-products in reclaimed water, etc., and achieve prediction accuracy Good effect of ensuring water quality safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The method for predicting the risk of residual chlorine in effluent water from a reclaimed water plant according to the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0030] The method for predicting the residual chlorine risk in reclaimed water plant effluent of the present invention comprises the following steps:

[0031] 1) Conduct data monitoring and collection;

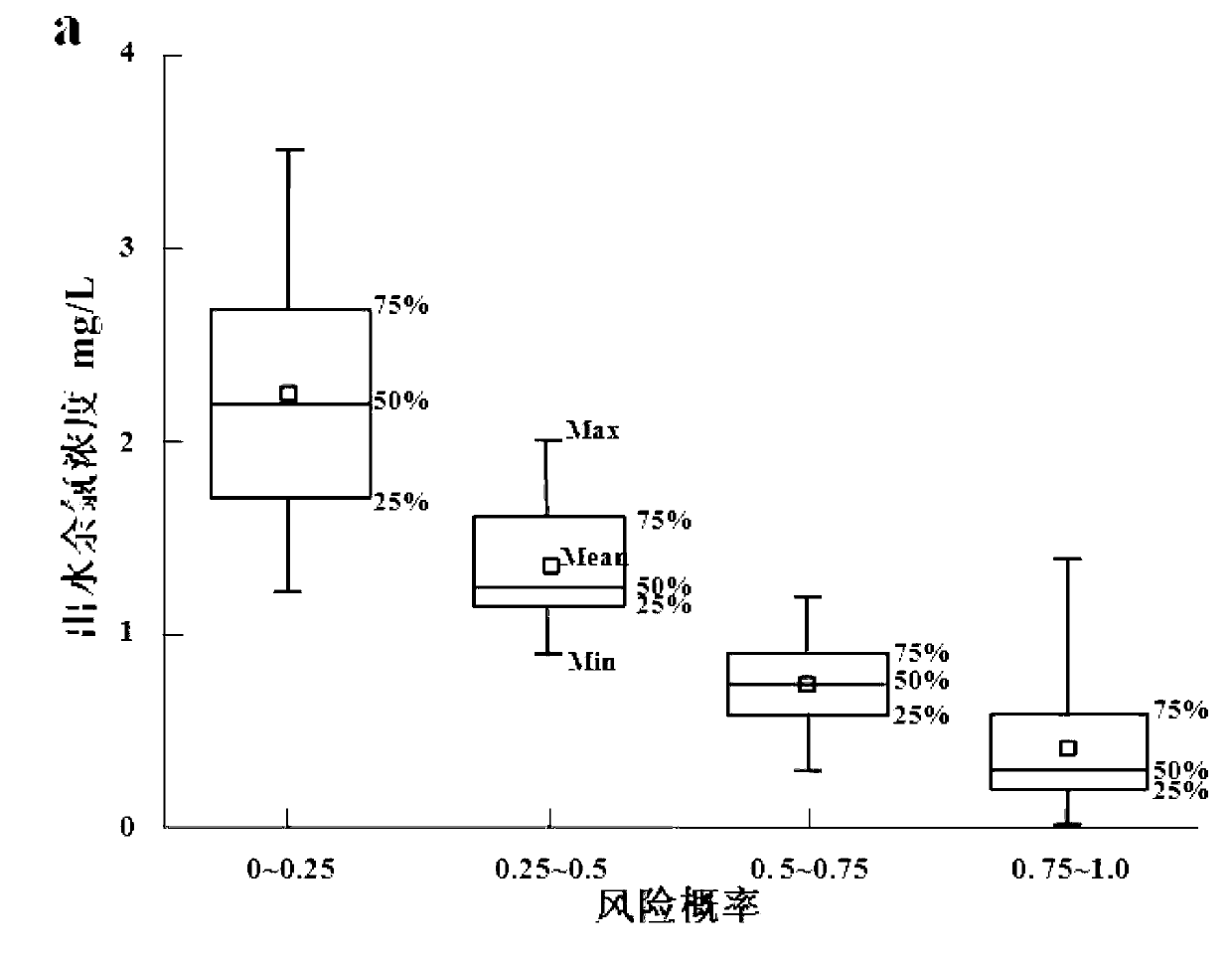

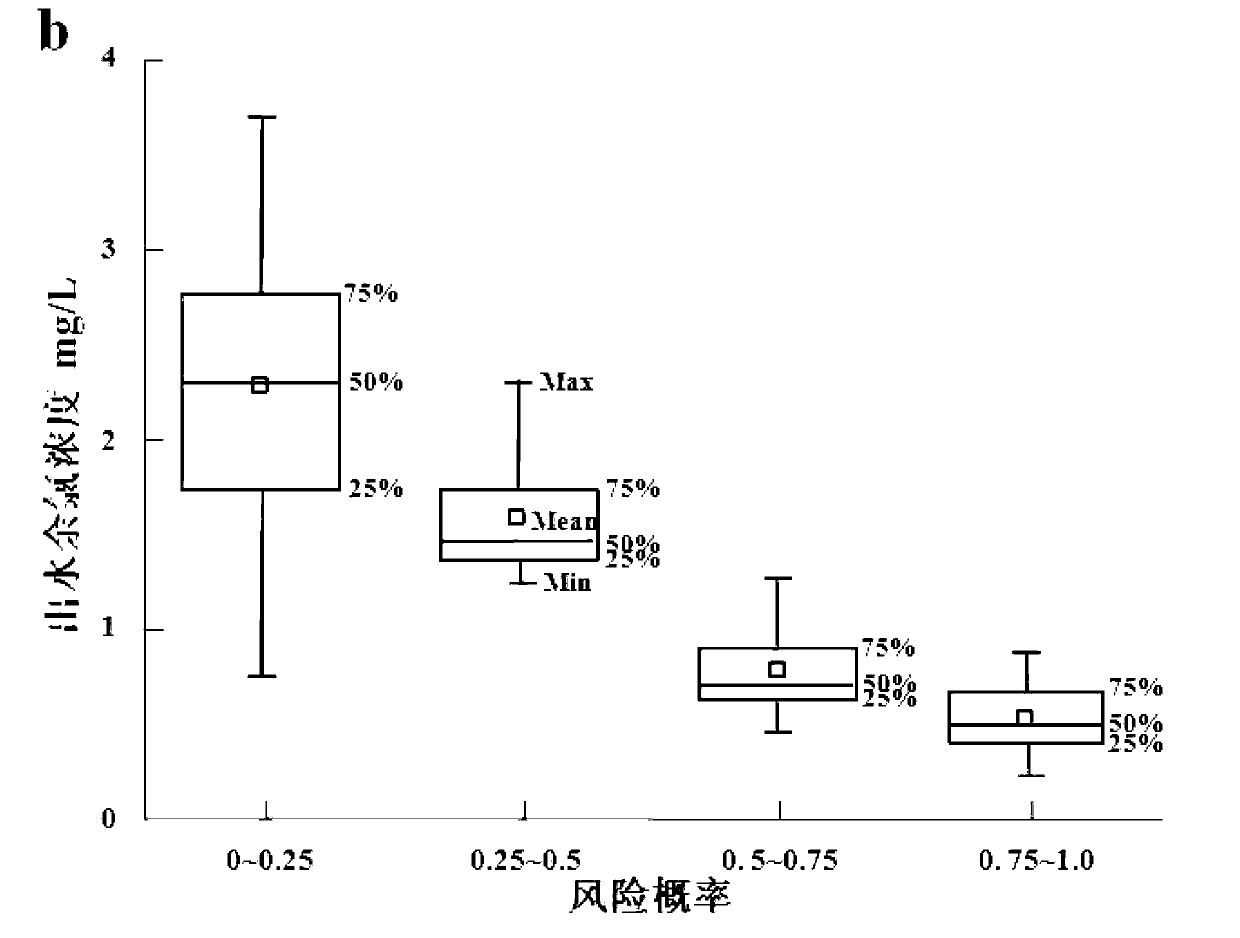

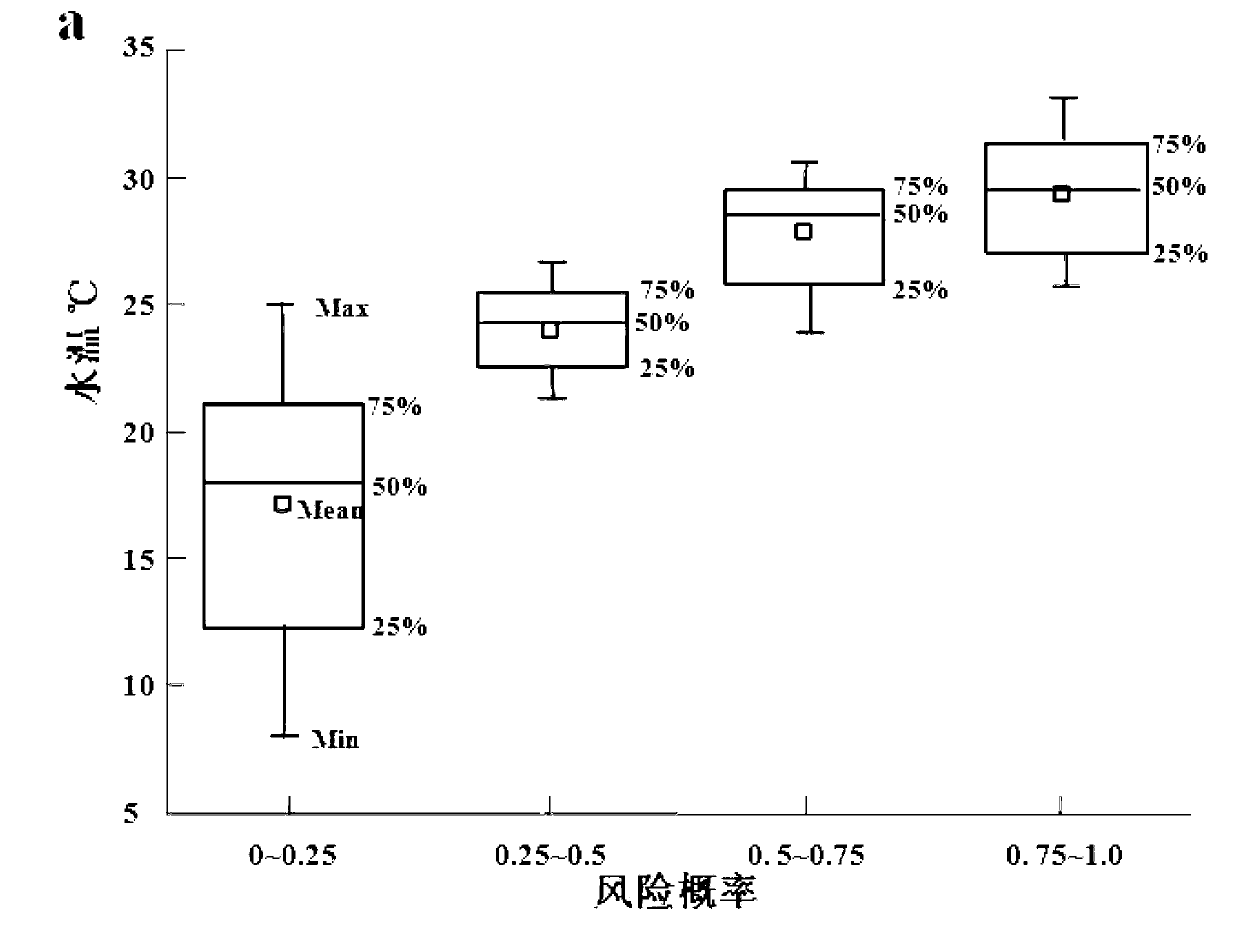

[0032] The data monitoring and acquisition system is the existing equipment of the water plant, which is composed of several telemetry and remote transmission terminals, and is used to collect the relevant physical and chemical index data of the water inflow and outflow monitoring points of the disinfection process of the water plant. The indicators monitored and collected include: the pH value, water temperature, ammonia nitrogen concentration and chemical oxygen demand of the influent of the chlorination process, and the total residual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com