Electric quick scraped car dismantler

A scrapped car, electric technology, applied in the field of work machinery, can solve the problems of high use cost, incomplete disintegration, and inability to cut, and achieves the effect of saving operating costs, improving expansion performance, and not easy to slip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

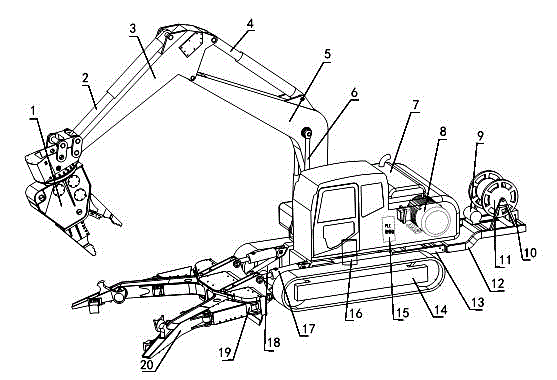

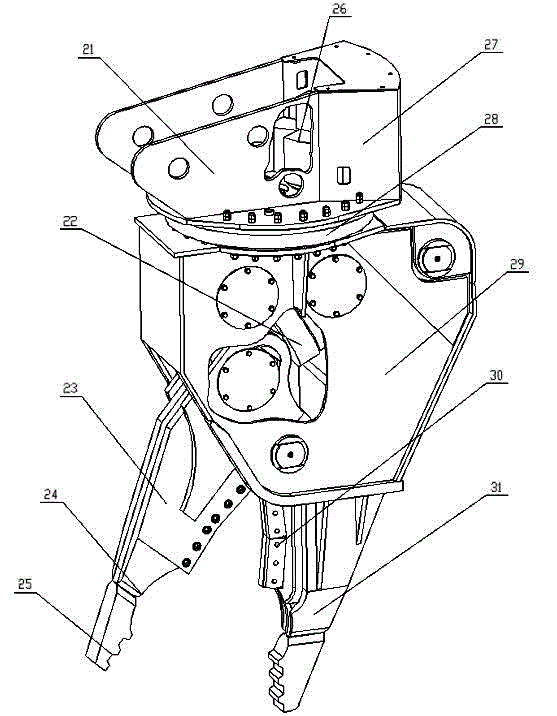

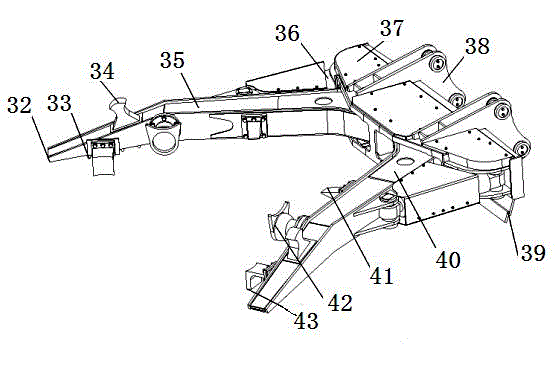

[0033] An electric fast dismantling machine for scrapped cars, which is composed of a special excavator for dismantling, a hydraulic shear for dismantling, a clamp arm for dismantling, and a power supply system; The upper end of the special stick is used, the clamping arm for dismantling is installed on the frame of the special excavator traveling device for dismantling, and the power supply system is respectively installed in the car body of the upper revolving body of the excavator for dismantling and between the traveling device and the upper revolving body of the excavator. between the racks.

[0034] On the basis of ordinary excavators, the special excavator for dismantling is equipped with a hydraulic shear telescopic cylinder 2, a special stick for dismantling 3, a telescopic stick cylinder 4, an excavator arm 5, a boom lifting cylinder 6, and a turning body on the car. 7. Traveling device 14, pincer arm lift cylinder 17, pincer arm mount 18;

[0035] The power supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com