Separated hoisting device of offshore wind turbine generator, and installation method

An offshore wind power and hoisting device technology, applied in wind turbine components, wind energy power generation, wind turbines and other directions, can solve the problems of poor installation stability, long installation time, low hoisting accuracy, etc. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

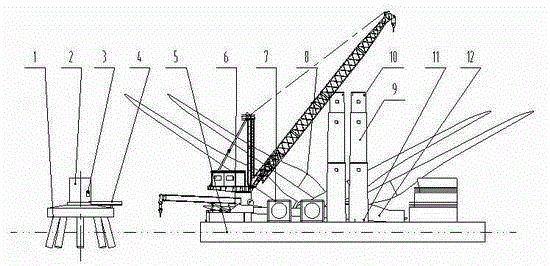

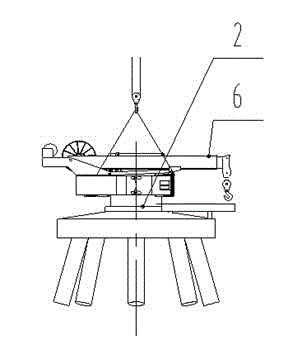

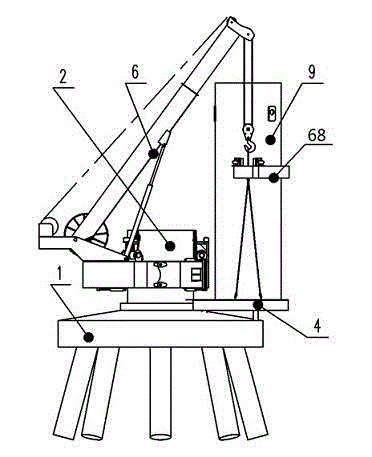

[0033] Combine below figure 1 with figure 2 , the present invention is further described:

[0034] The tower self-elevating crane 6 includes a lifting system, a self-elevating system, a fixing system, a machine platform 62, a balance beam spreader 67, a tower spreader 68, special fixtures for blades, a hydraulic system, a power supply system, a control system, and an operating system .

[0035] Specifically:

[0036] 1.1. Lifting system.

[0037] The lifting system is mainly composed of jib, luffing cylinder, hydraulic winch, wire rope-pulley block and base. There are two sets in total, which are symmetrically arranged on both sides of the machine platform. They can be operated in conjunction or independently.

[0038] 1.1.1. Boom.

[0039] The jib can be a two-section telescopic box or fixed-length truss jib. The structural form of the two-section telescopic jib has the advantages of compact structure and beautiful appearance, and the fixed-length truss jib has the adv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap