Method for synthesizing SAPO-34 molecular sieve by taking A type zeolite as silicon source

A synthesis method and molecular sieve technology, applied in the direction of molecular sieves and alkali-exchanged phosphates, etc., can solve problems that are difficult to control, affect the number and shape of silicon entering the skeleton, and affect catalytic reaction performance, so as to achieve uniform distribution of skeleton silicon and improve catalytic reaction performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

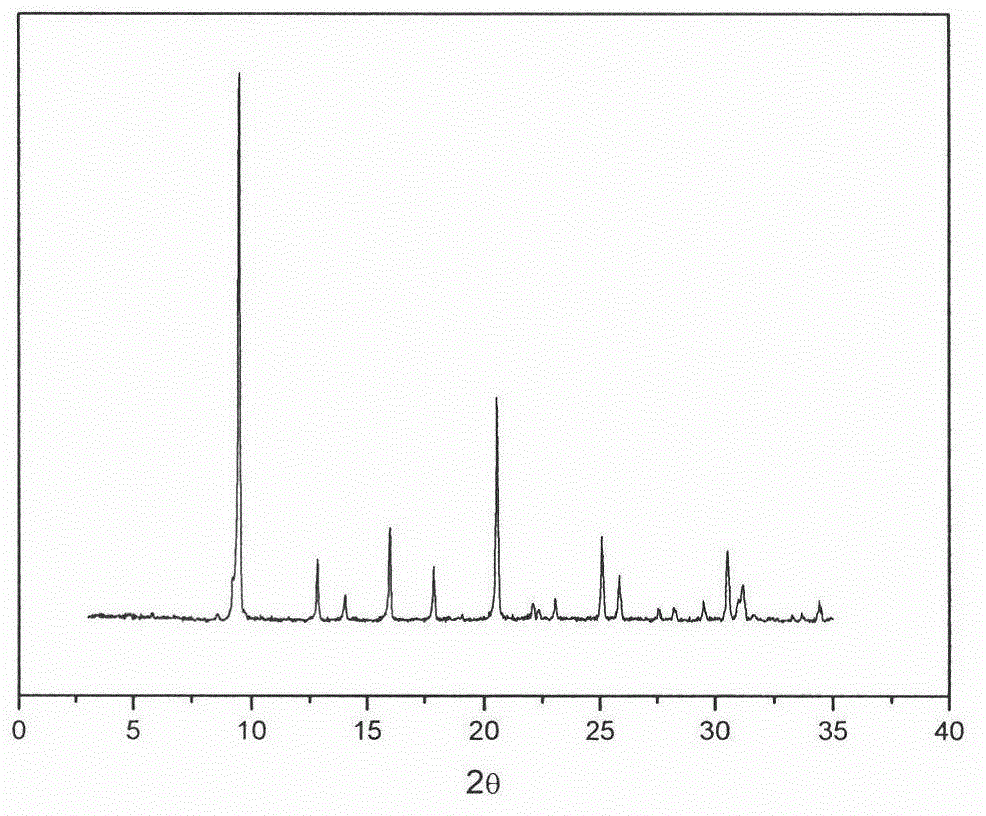

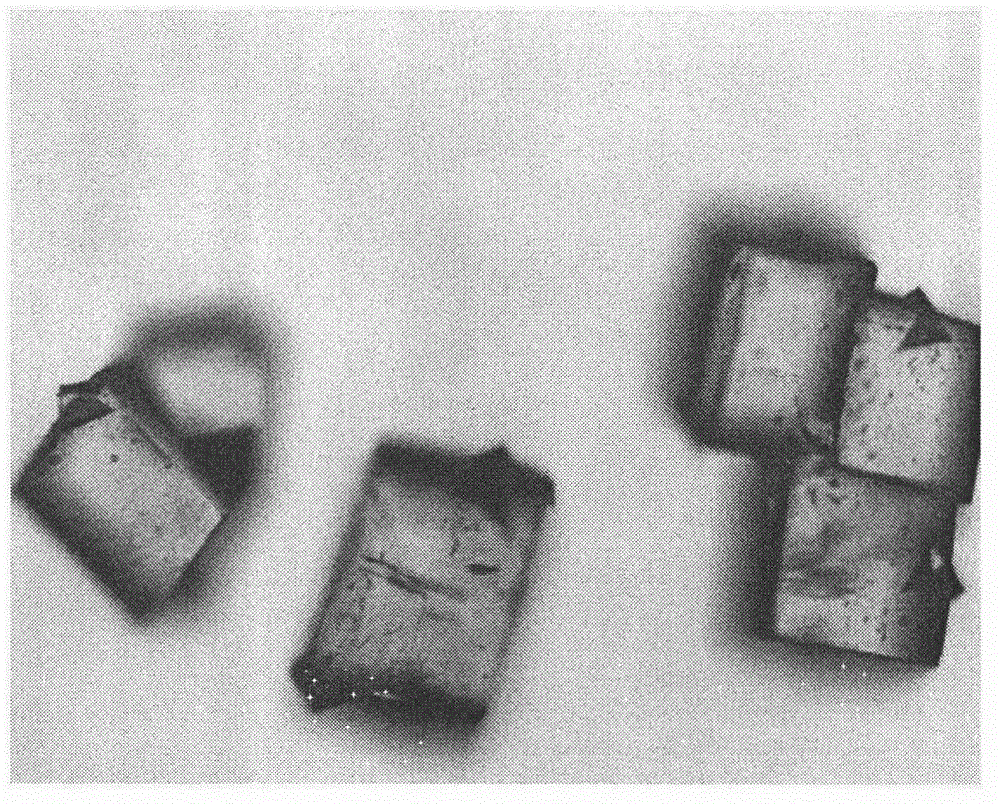

Image

Examples

Embodiment 1

[0014] Hydrothermally treat 0.608g of type A zeolite at 100°C for 2 hours, dissolve 1.74g of pseudoboehmite powder and treated type A zeolite with 10mL of deionized water at 20°C, then add 1.51mL of phosphoric acid and 2.3mL of diethyl Amine, stirred evenly, moved into a stainless steel reactor for crystallization at 200°C for 5-6 days, then cooled, washed, dried, and collected the product according to the conventional molecular sieve post-treatment method.

Embodiment 2

[0016] Hydrothermally treat 0.203g of type A zeolite at 100°C for 2 hours, dissolve 1.74g of pseudoboehmite powder and treated type A zeolite with 10mL of deionized water at 20°C, then add 1.51mL of phosphoric acid and 2.3mL of diethyl Amine, stirred evenly, moved into a stainless steel reactor for crystallization at 200°C for 5-6 days, then cooled, washed, dried, and collected the product according to the conventional molecular sieve post-treatment method.

Embodiment 3

[0018] Hydrothermally treat 1.216g of type A zeolite at 100°C for 2 hours, dissolve 1.74g of pseudoboehmite powder and treated type A zeolite with 10mL of deionized water at 20°C, then add 1.51mL of phosphoric acid and 2.3mL of diethyl Amine, stirred evenly, moved into a stainless steel reactor for crystallization at 200°C for 5-6 days, then cooled, washed, dried, and collected the product according to the conventional molecular sieve post-treatment method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com