Gene engineering bacterium for efficiently reducing azo dyes, and construction method and application thereof

A technology of genetically engineered bacteria and azo dyes, applied in the field of genetically engineered bacteria and its construction for efficient reduction of azo dyes, can solve problems such as unsatisfactory growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

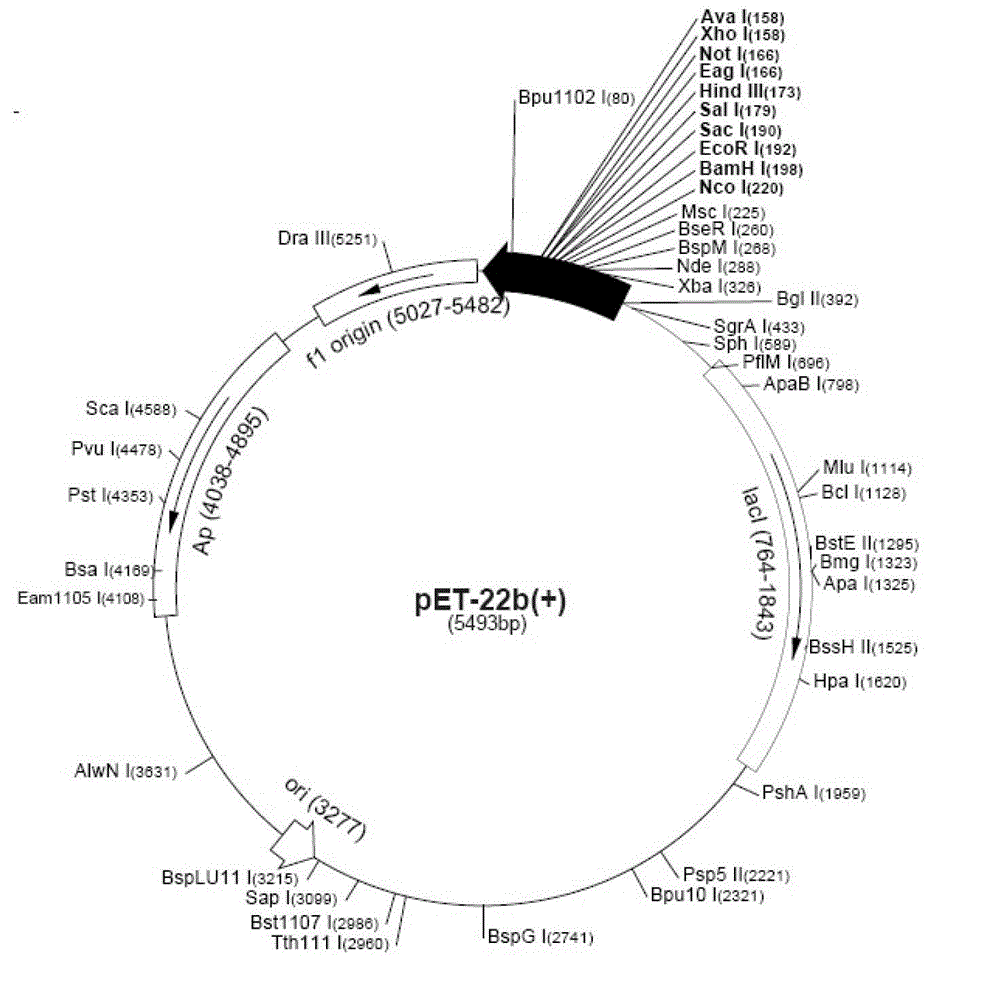

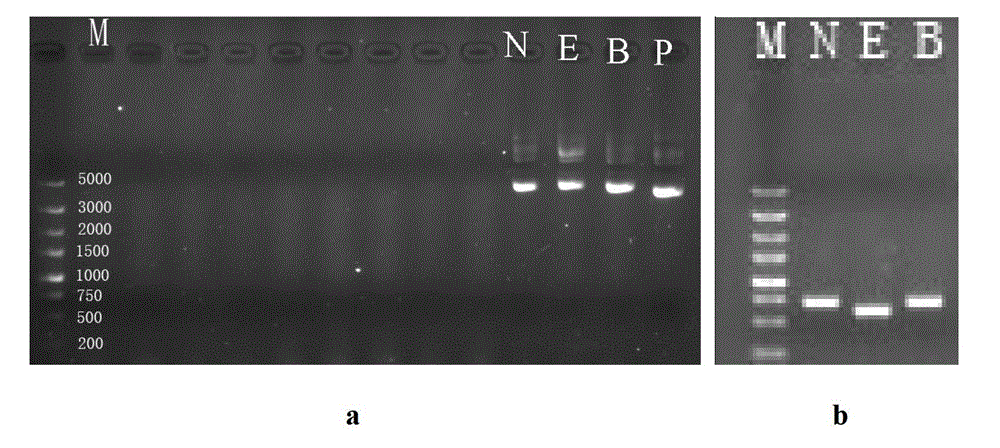

[0018] Example 1: Construction method of genetically engineered bacteria E.coli BL21(DE3) / azoR for efficiently reducing azo dyes

[0019] (1) Primer design;

[0020] According to the riboflavin-dependent NADH-azo reductase of S. decolorationis S12, the open reading frame and upstream promoter of the azoR gene (its Genebank accession number EF198254) (its Genebank accession number EF647586) Sequence, select its upstream and downstream conserved sequences to design upstream primer U and downstream primer D, and add NdeI restriction endonuclease enzyme cutting site sequence at the 5' end of upstream primer U, and add The sequence of the cutting site of the XhoI restriction endonuclease. The base sequences of primers U and D are as follows, and the underlined parts are the restriction site sequences of NdeI and XhoI restriction endonucleases, respectively.

[0021] Upstream primer U: GGAATTC CATATG TCCGCTTTTTTTTCTTTTTTA

[0022] Downstream primer D: CCG CTCGAG AACAGCTAACTTA...

Embodiment 2

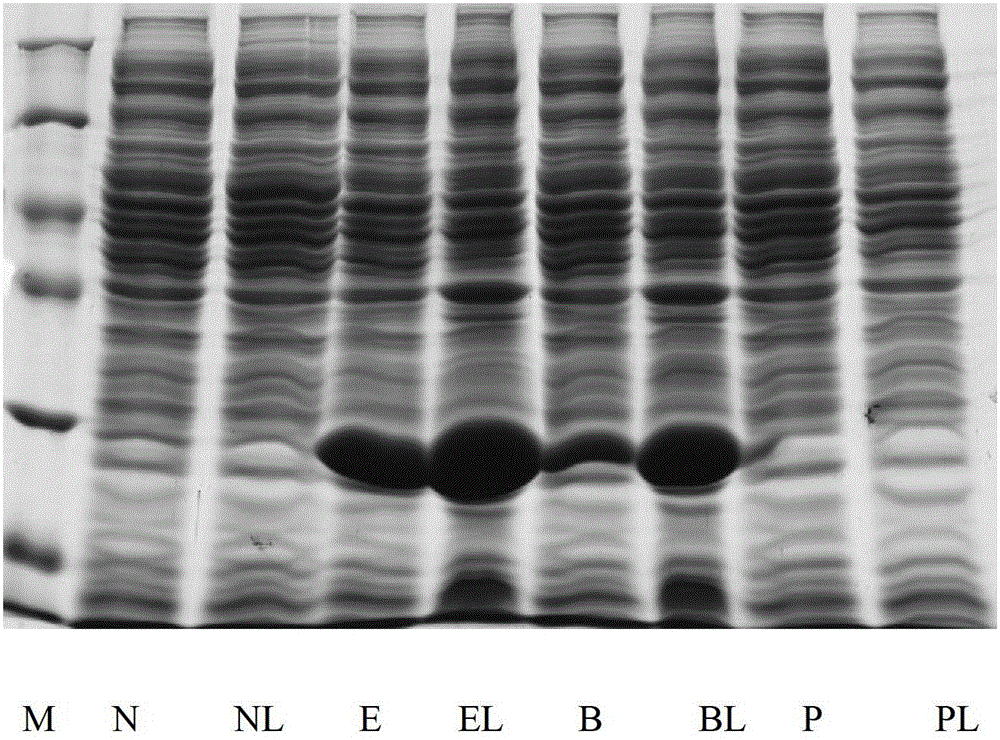

[0037] Example 2: Induced expression of azoreductase in genetically engineered bacteria E.coli BL21(DE3) / azoR

[0038] (1) Induction of genetically engineered bacteria

[0039] The genetically engineered bacteria E.coli BL21(DE3) / azoR were inoculated in LB liquid medium and cultured overnight at 37°C in a shaker with a rotation speed of 200rpm / min. Inoculate the overnight culture into fresh LB liquid medium with an inoculum amount of 1.5%, and cultivate it in a shaker at 37°C with a rotation speed of 200rpm / min. 600 When it reaches 0.6, add 0.4mM lactose to induce, and induce at 30°C for 4h.

[0040] (2) Preparation of crude enzyme solution

[0041] Centrifuge the induced bacterial solution at 12,000×g for 10 min, remove the supernatant, and collect the bacterial cells. Wash the bacteria twice with phosphate buffered saline (PBS, pH7.4), and finally resuspend in a certain volume of buffer to make the bacterial solution A 600 About 0.8. The bacterial liquid was crushed for...

Embodiment 3

[0045] Embodiment 3: Enzyme activity comparison of different bacterial strains crude enzyme liquid

[0046] According to Example 2, the crude enzyme solution of genetically engineered bacteria E.coli BL21(DE3) / azoR under induction conditions was prepared. Transform the strains E.coli BL21(DE3) / azoR, E.coli BL21(DE3), E.coli BL21(DE3) / pET-22b(+) into the empty vector pET-22b in E.coli BL21(DE3) (+)) and S.decolorationis S12 were inoculated in LB liquid medium and cultured overnight in a shaker at 37°C (30°C for S.decolorationis S12) with a rotation speed of 200rpm / min. The overnight culture was inoculated into fresh LB liquid medium at an inoculum volume of 1.5%, and cultured in a shaker at 37°C (30°C for S. decolorationis S12) at a speed of 200rpm / min until the genetically engineered bacteria induced expression The time required for cultivation (in bacterial solution A 600 reached 0.6), and then prepare the crude enzyme solution.

[0047] The enzyme activity assay was carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com