Multi-functional continuous magneto-controlled sputter coating device

A magnetron sputtering coating, multi-functional technology, applied in the direction of sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of low production efficiency, waste of energy, difficult installation and processing, etc., to prevent Ineffective area, improved versatility, and the effect of avoiding pinch marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

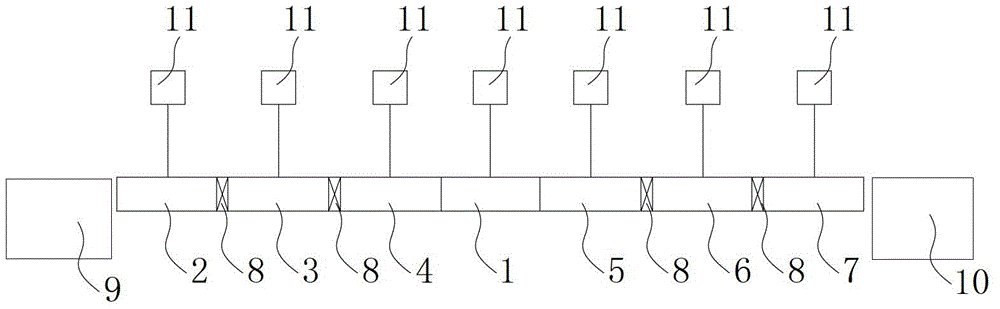

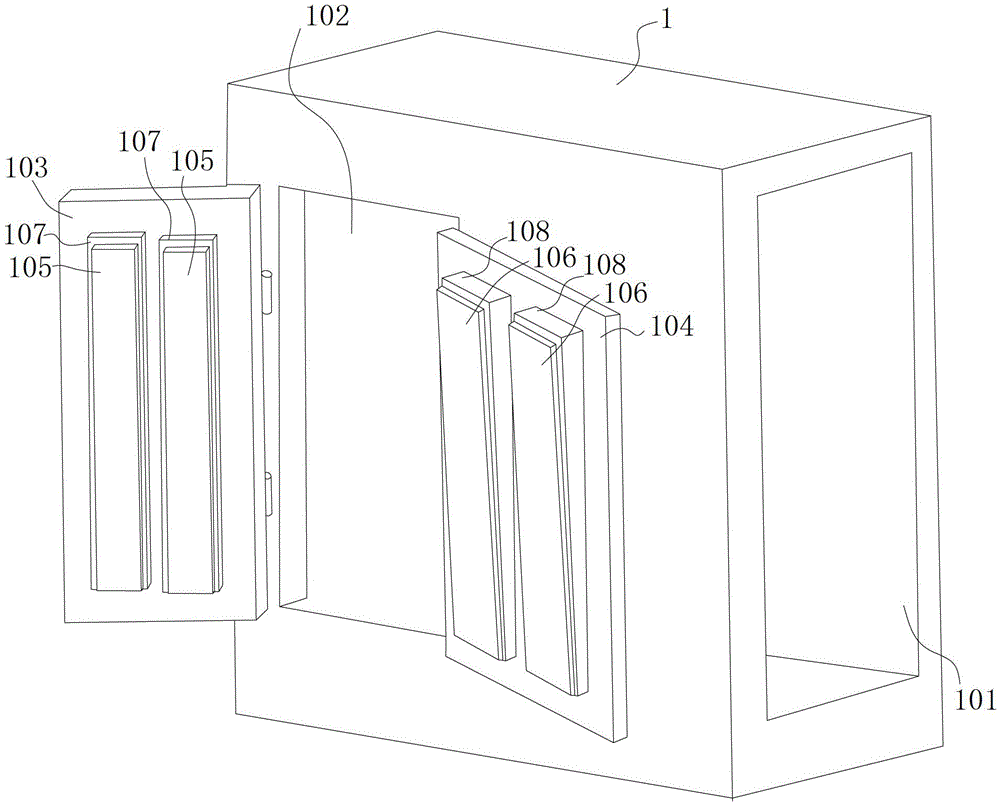

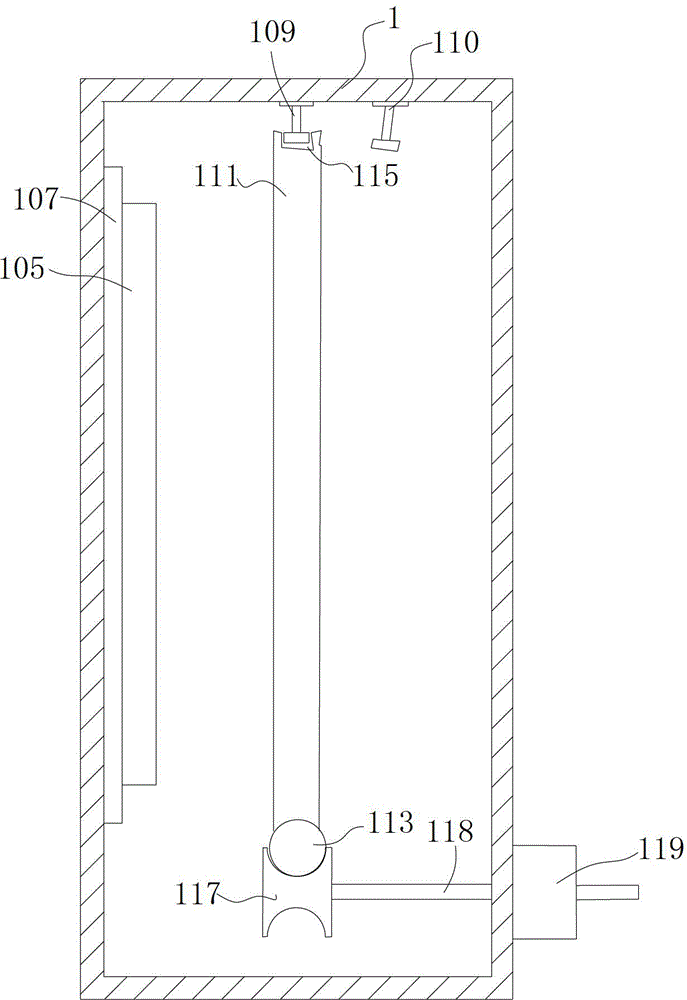

[0038] Such as figure 1 As shown, the multifunctional continuous magnetron sputtering coating device described in this embodiment includes a film feeding chamber 2, a first transition chamber 3, a first coating buffer chamber 4, a coating chamber 1, and a second coating chamber arranged in sequence. The buffer chamber 5, the second transition chamber 6, and the film output chamber 7, the feeding station 9 is set on the side of the film feeding chamber 2 away from the first transition chamber 3, and the film output chamber 7 is far away from the side of the second transition chamber 6 The unloading station 10 is set, the isolation valve 8 is set between the film feeding chamber 2 and the first transition chamber 3, the isolation valve 8 is set between the first transition chamber 3 and the first coating buffer chamber 4, and the second coating buffer chamber 5 and An isolation valve 8 is arranged between the second transition chamber 6, an isolation valve 8 is arranged between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com