Gas-liquid one-way mixing device for urea pump

A technology of mixing device and urea pump, applied in the field of urea pump, can solve problems such as one-way mixing of gas and liquid, and achieve the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

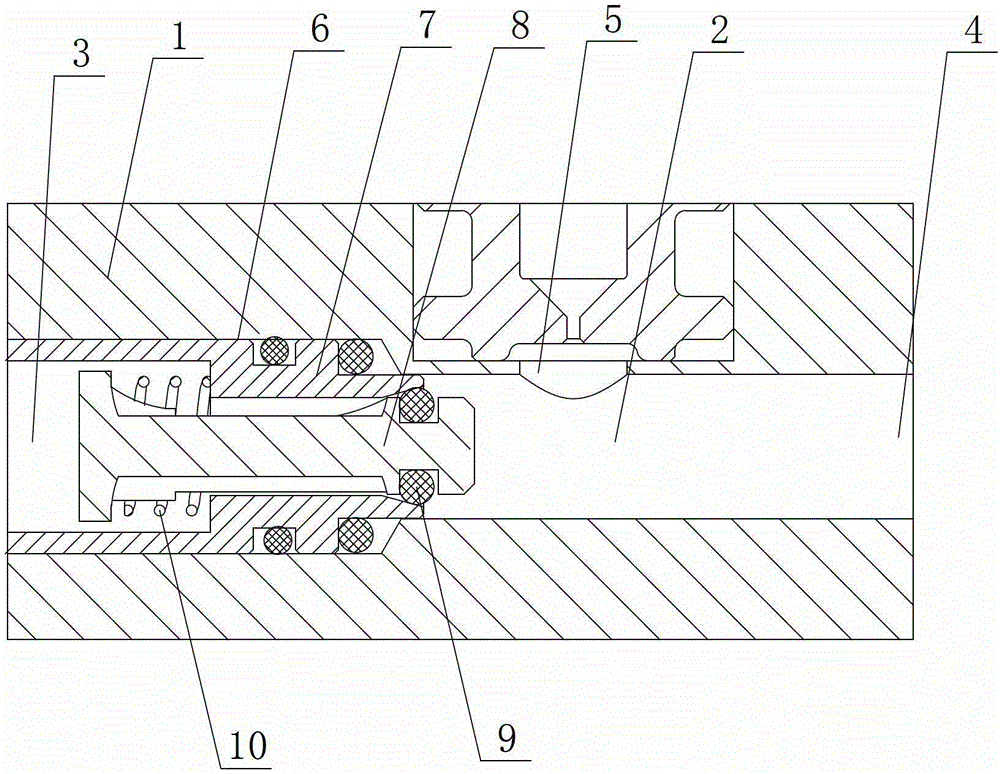

[0017] see figure 1 as shown, figure 1 It is a schematic structural diagram of a gas-liquid one-way mixing device for a urea pump provided in Embodiment 1 of the present invention.

[0018] In this embodiment, a gas-liquid one-way mixing device for a urea pump includes a housing 1, and a mixing chamber 2 is opened in the housing 1, one end of the mixing chamber 2 is a gas inlet 3, and the other end is a The mixed liquid outlet 4, and the housing 1 is provided with a urea solution inlet 5 at a position corresponding to the mixing chamber 2, and the urea solution inlet 5 adopts a structure that enters the mixing chamber 2 vertically, and the structure makes the degree of gas-liquid mixing Preferably, one end of the gas inlet 3 on the mixing chamber 2 is provided with a one-way valve 6 that is sealed with the inner wall of the housing 1. The one-way valve 6 includes a valve seat 7 and a piston 8, and the piston 8 passes through a " The O"-shaped sealing ring 9 is in sealing con...

Embodiment 2

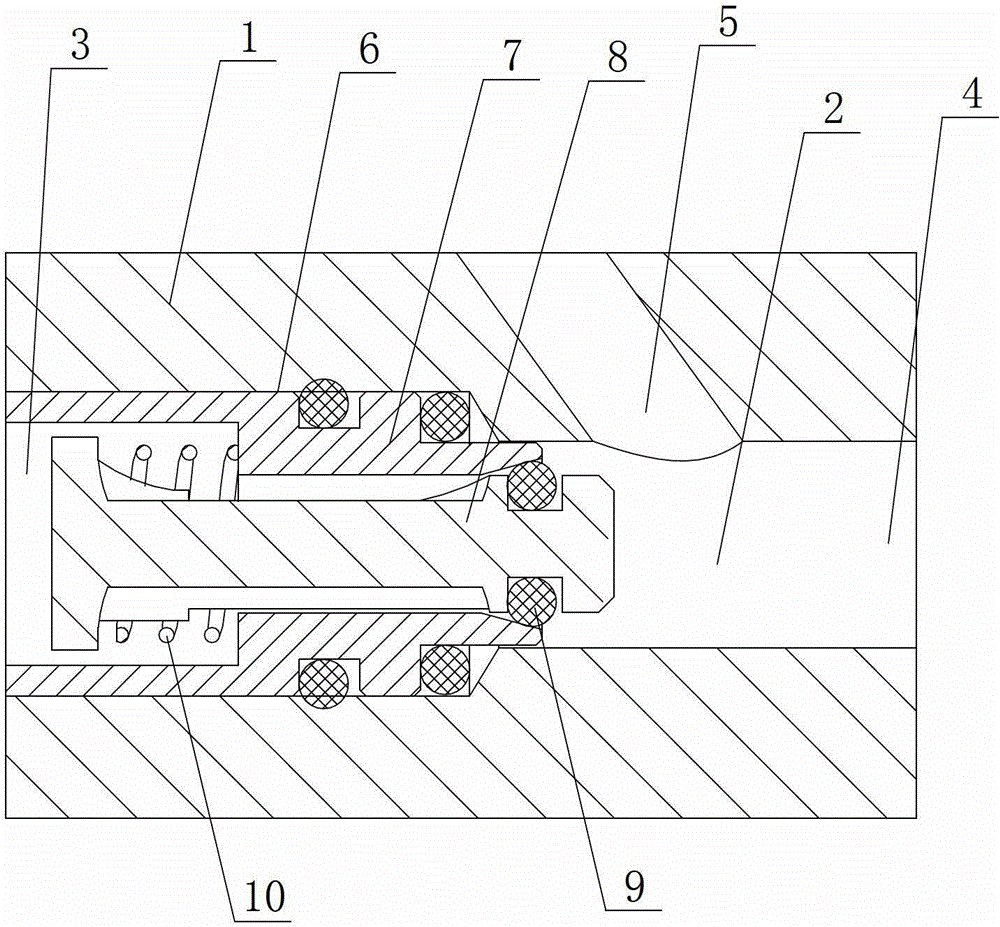

[0020] see figure 2 as shown, figure 2 It is a schematic structural diagram of a gas-liquid one-way mixing device for a urea pump provided in Embodiment 2 of the present invention.

[0021] In this embodiment, the difference from Embodiment 1 lies in the angle at which the urea solution inlet 5 enters the mixing chamber 2. In this example, the structure of entering the mixing chamber 2 obliquely downward is adopted, and this structure makes it easier to discharge gas and liquid after mixing in the mixing chamber 2. smooth.

[0022] When working, when the pressure in the mixing chamber 2 is greater than the pressure at the gas inlet 3 end, the sealing ring of the check valve 6 will seal the piston 8 to prevent the urea mixture from entering the gas circuit. When the internal pressure is high, the piston 8 of the one-way valve 6 opens, and the gas enters the mixing chamber 2 to meet the requirement of mixing with urea, and is discharged from the mixed liquid outlet 4 after m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap