Casting asphalt concrete multi-function test and formation apparatus

A technology of asphalt concrete and forming device, which is applied in the field of experimental equipment, can solve the problems affecting the construction quality, the porosity of hydraulic asphalt concrete specimens cannot be guaranteed, and the test data of asphalt concrete is not accurate enough, so as to achieve convenient reading, reasonable structure, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

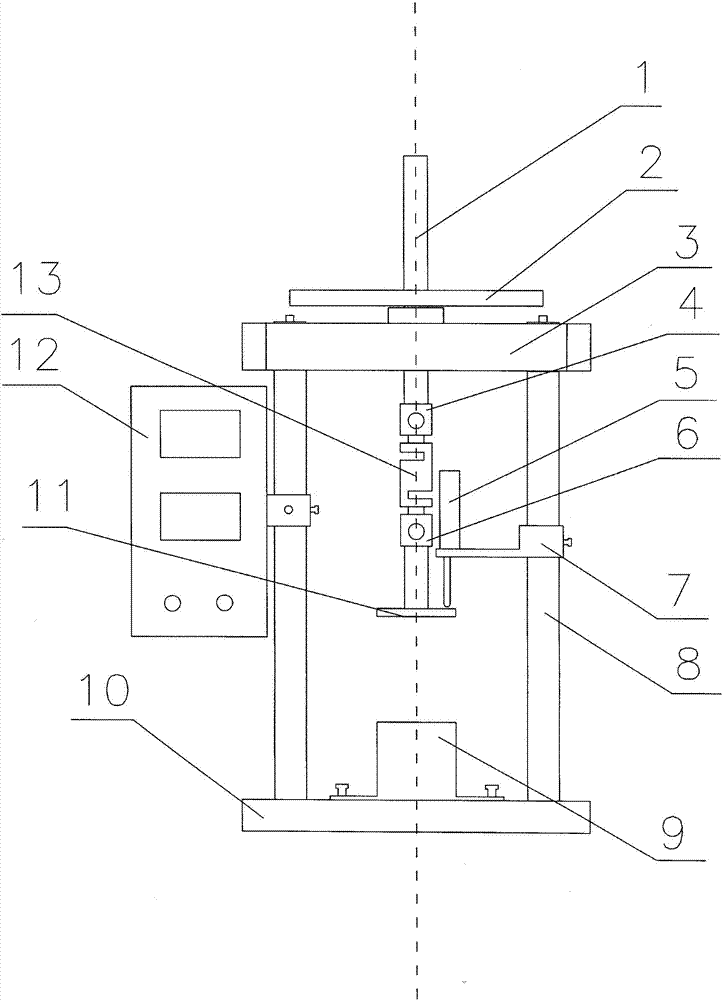

[0008] A pouring type asphalt concrete multifunctional test and forming device, such as figure 1 As shown, the base 10 is fixed to the column 8, and the upper end of the column 8 is fixed to the support plate 3. In the screw hole provided by the support plate 3, the screw rod 1 with the rotary handle 2 on the top is fitted with a threaded rod 1 located on the support plate 3. A pressure sensor 13 is installed at the end of the screw rod 1 below, and a steel pressure plate 11 is affixed to the lower part of the pressure sensor 13; Its contact is matched with the top surface of steel pressing plate 11, and on base 10, is affixed with the trial mold 9 that matches with the bottom surface of steel pressing plate 11, pressure and deformation display box 12 are installed on another column. A pressure sensor 13 is connected to the end of the screw rod 1 through the installed upper fixing collar 4 . The lower end of the pressure sensor 13 is connected to the support column of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com