A manufacturing process of an annular heat accumulator and the annular heat accumulator

A production process and technology of heat accumulator, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of different useless volumes, easy curling, uneven wire mesh, etc., and achieve the efficiency of heat accumulator. High, low heat flow loss, good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

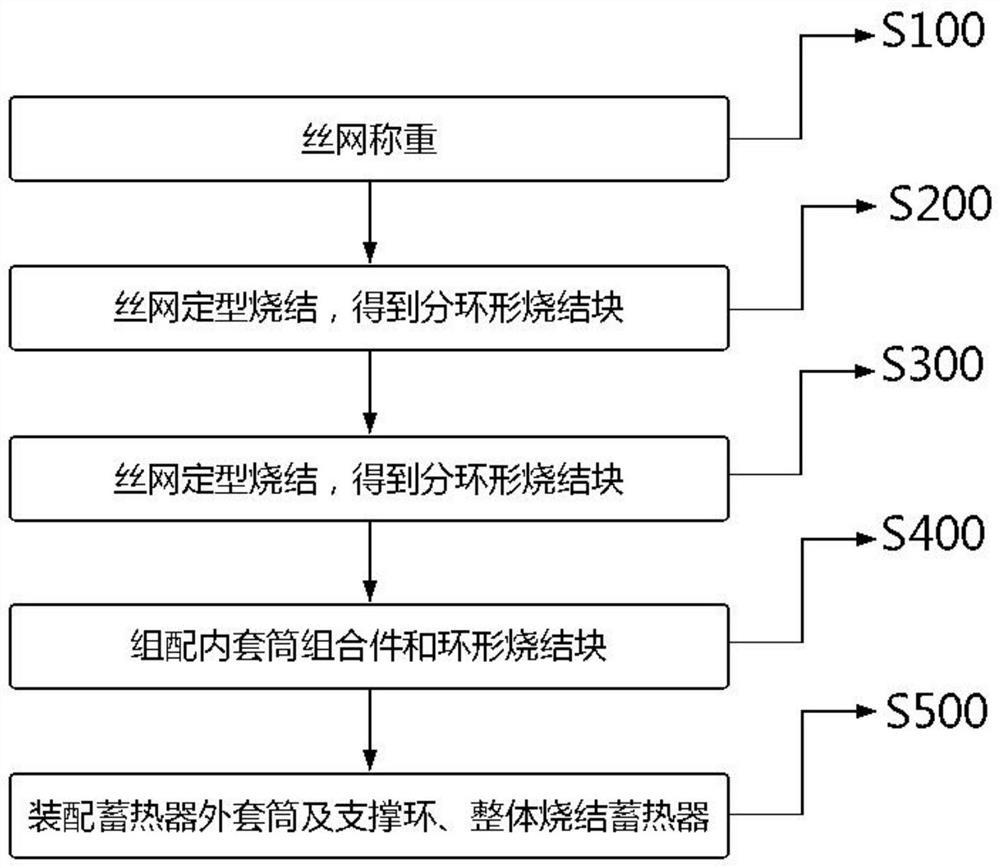

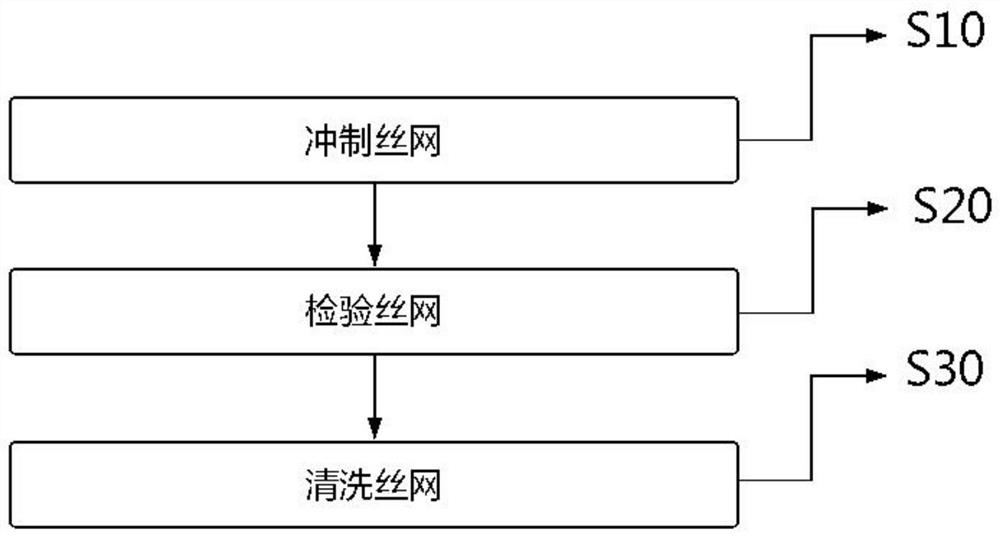

[0067] Embodiment two, on the basis of embodiment one, such as figure 2 As shown, the flow chart of making silk screen.

[0068] Concretely, before the silk screen weighing in step S100 includes making the silk screen, it specifically includes the following steps:

[0069] Step S10: punching the screen;

[0070] Step S20: inspecting the quality of the silk screen;

[0071] Step S30: cleaning the screen.

[0072] Fabricating the wire mesh through the above steps can meet the quality requirements of the annular heat accumulator 100 for the wire mesh.

Embodiment 3

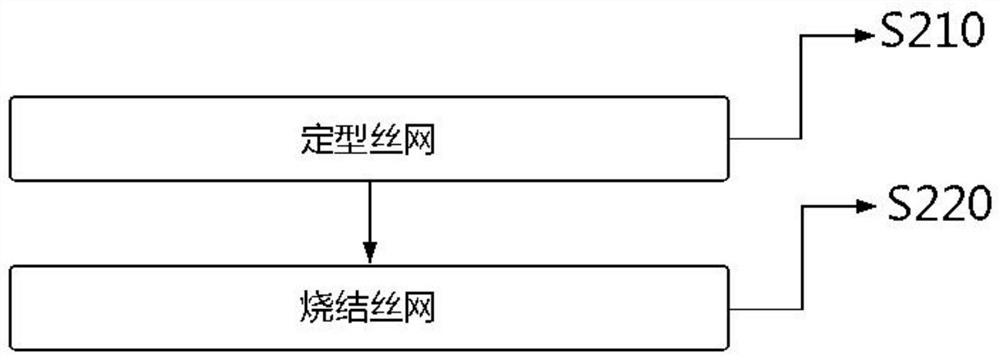

[0073] Embodiment three, on the basis of embodiment two, such as image 3 Shown, the flow chart of making screen sintered block 101.

[0074] Specifically, step S200 includes the following steps:

[0075] Such as Figure 4 As shown, step S210: shape the screen and apply pressure to obtain a shaped part of the screen;

[0076] Step S220: After unloading the sizing pressure, sintering the stenciled wire mesh part.

[0077] The above steps can solve the problem of unevenness and easy curling of the wire mesh, and further solve the gap between the wire mesh and the wire mesh, so that the porosity of the annular heat accumulator 100 can be precisely controlled, so the annular heat accumulator 100 The consistency can be precisely controlled.

Embodiment 4

[0078] Embodiment four, on the basis of embodiment three, such as Figure 5 As shown, the flow chart of the subsequent fabrication process.

[0079] Specifically, step S500 also includes the following steps:

[0080] Such as Figure 6 As shown, step S510: thermal sleeve of the outer sleeve, put the outer sleeve 103 of the heat accumulator into an oven for heating, and heat the outer sleeve 103 of the heat accumulator to the sintered block 101 after heating, so as to ensure the storage capacity during assembly. The bottom support of the heater outer sleeve 103 is attached to the screen sintered block 101 . A machining allowance of 0.2-0.4 mm should be left on the outer surface of the heat accumulator outer sleeve 103;

[0081] Such as Figure 7 As shown, step S520: component assembly, assemble the lower support ring 104 on the above-mentioned assembly, and add adhesive and nickel-based solder at the contact position between the lower support ring 104 and the assembly (the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com