Method for determining parameter influence factors of cut tobacco drying process based on partial least square (PLS)

A technique of affecting factors and drying silk, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., and can solve the problem of being unable to determine the size of the influencing factors of silk drying process parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing.

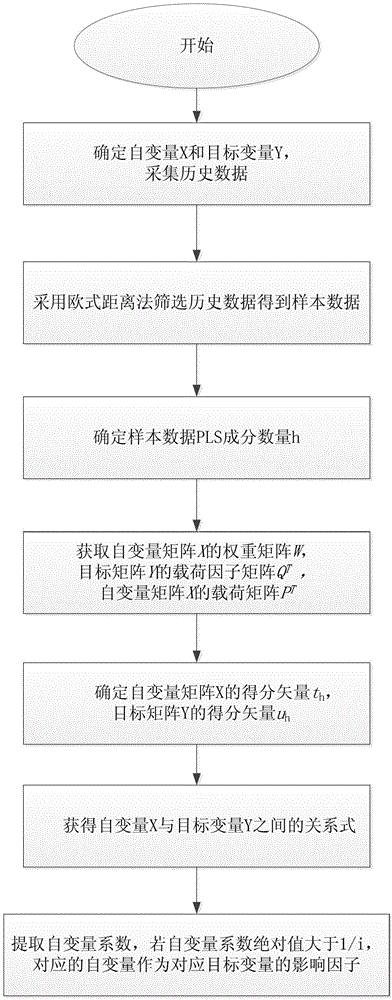

[0042] Taking the production of a certain type of cigarettes in a tobacco factory as an example, a method for determining the influencing factors of drying process parameters based on PLS, the schematic flow chart is as follows figure 1 shown.

[0043] 1) Determination of target variable y and independent variable x and collection of historical data

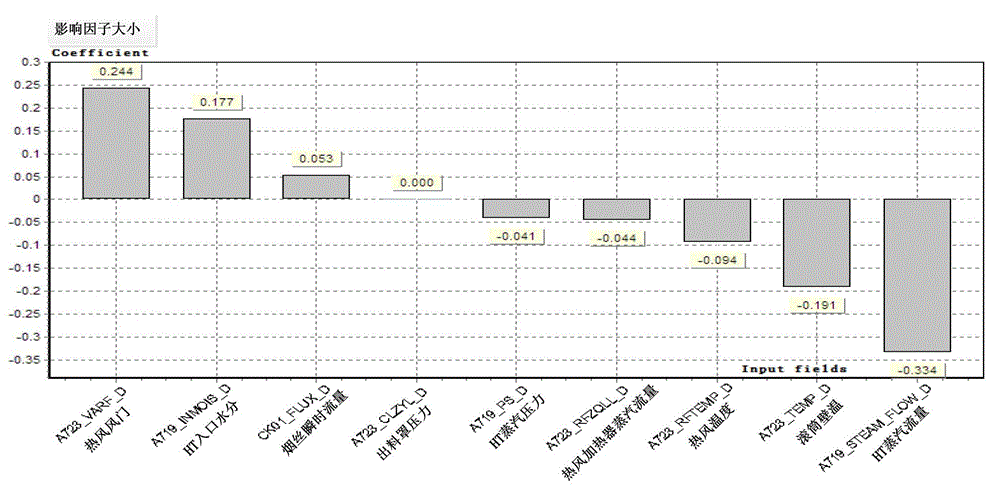

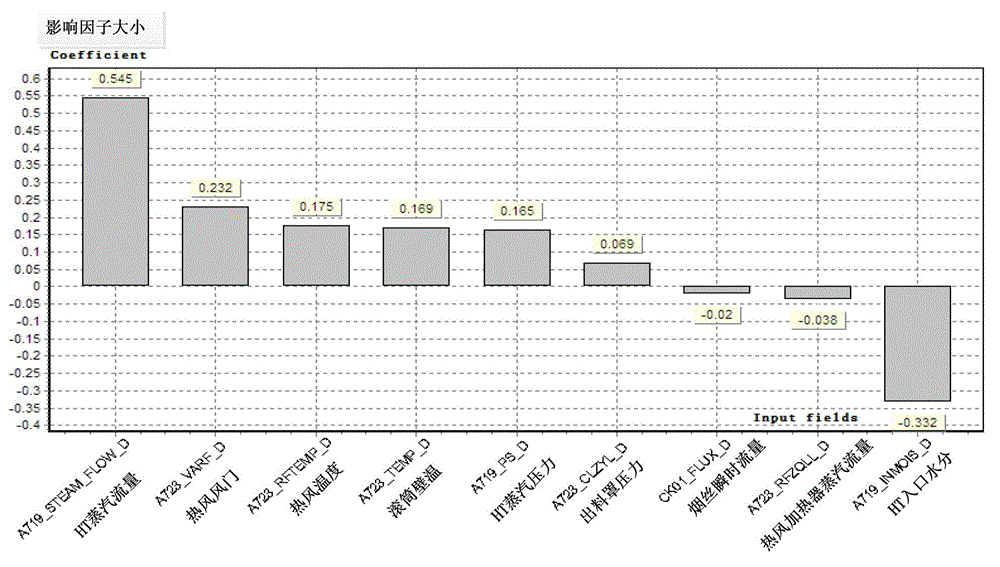

[0044]There are many process parameters involved in the silk drying process, including process data of HT section (HT steam pressure, HT steam flow rate, inlet moisture, etc.); drum inlet process data (drum inlet hot air temperature, drum inlet hot air volume, etc.); Cylinder wall parameter data (tube wall temperature, cylinder wall steam pressure, etc.); tidal wind parameter data (tidal exhaust damper opening, discharge hood negative pressure, etc.) and shredded tobacco discharge parameter data (discharge shredded tobacco mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com