High-efficiency mesh channel hierarchical air filtering structure

A technology of air filtration and stage filtration, which is applied in the direction of dispersed particle filtration, separation method, and separation of dispersed particles. More, increase the effect of effective filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

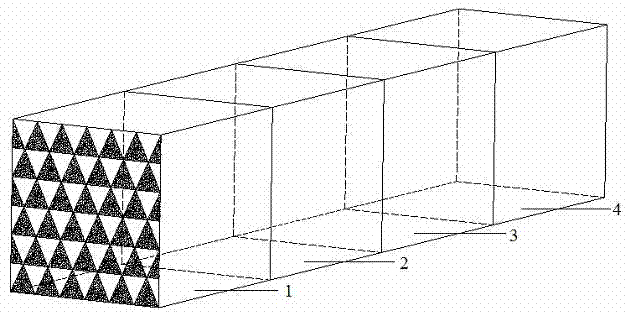

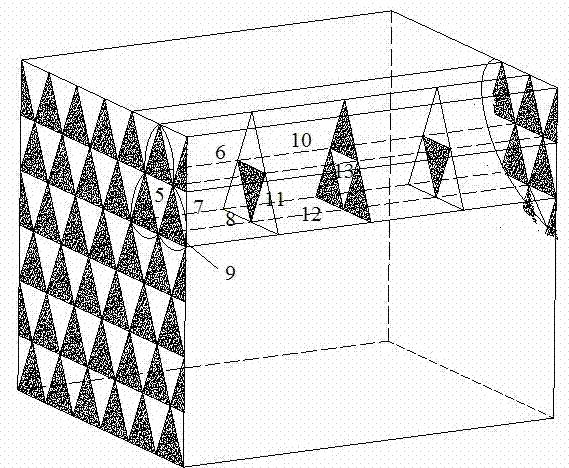

[0022] The following is attached Figure 1-4 The present invention will be further described in detail with the specific examples completed by the inventor according to the technical solution of the present invention.

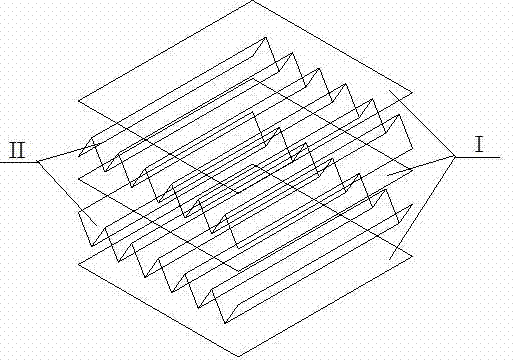

[0023] figure 1 As shown, the overall structure of the present invention is composed of four-stage filter structures, which are the first-stage filter structure 1, the second-stage filter structure 2, the third-stage filter structure 3 and the fourth-stage filter structure 4 along the air flow direction. Among them: the first stage filter structure 1 is separated by coarse particle filter material, the second stage filter structure 2 is separated by medium particle filter material, the third stage filter structure 3 is separated by fine particle filter material and the fourth stage filter structure 4 Separated by gaseous pollutants adsorption filter material. The specific example selects the first-stage filter structure 1 to illustrate the present invention,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com