Preparation method of pavement material self-repairing microcapsule

A technology for self-repairing microcapsules and pavement materials, which is applied in the field of preparing self-repairing microcapsules for pavement materials, can solve the problems of poisoning, high cost, and difficulty in removing toxic compounds, and achieves the effect of reducing costs and efficiently repairing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The method for preparing self-healing microcapsules for pavement materials of the present invention is characterized in that the raw materials are prepared according to the following mass percentages: gelatin: 4% to 6%, gum arabic: 4% to 6%, and epoxy resin: 8 %~12%, emulsifier: 25%~35%, formaldehyde: 6%~10%, pH regulator: 1%~5%, water: 40%~50%, the sum of the percentages of the above raw materials is 100%.

[0023] Table 1 The mass percentage of each component of the microcapsule

[0024]

[0025]

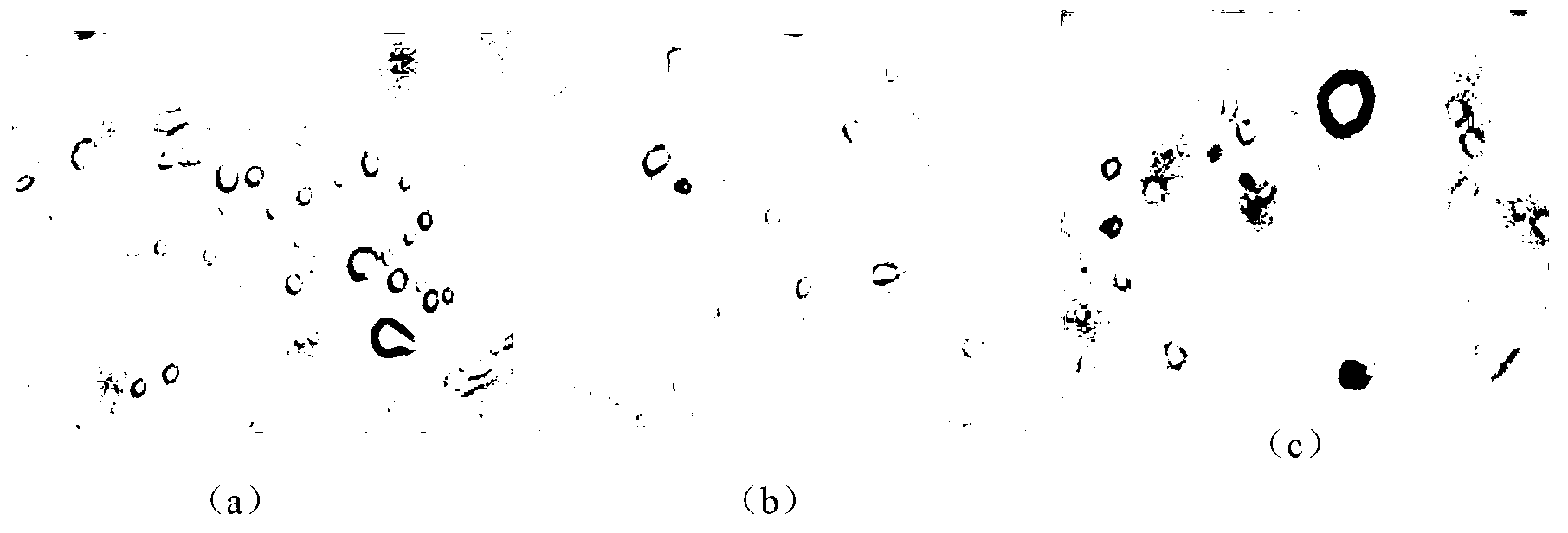

[0026] Table 1 shows the 10 formulations of microcapsules. Observed under a microscope, the microcapsules prepared by the first, fourth, fifth, eighth, ninth, and tenth formulations have better appearance. In the process of microcapsule synthesis, the mass ratio of the capsule wall and the capsule core will have a decisive influence on the formation process and results of the microcapsule, mainly related to the size and wall thickness of the microcapsule and whether the capsule ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com