High-speed EMU air-conditioning duct system

A technology for high-speed EMUs and air-conditioning air ducts, which are applied in railway car body parts, railway vehicle heating/cooling, transportation and packaging, etc., to achieve the effect of satisfying comfort, simple overall structure, and uniform airflow organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

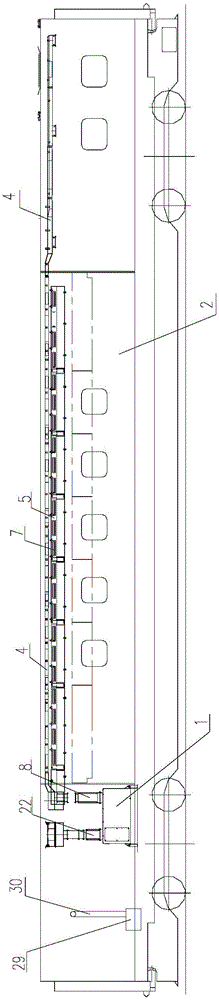

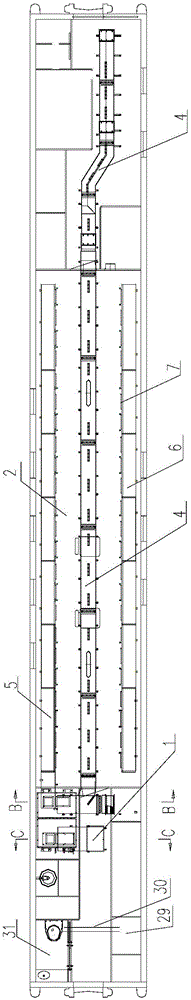

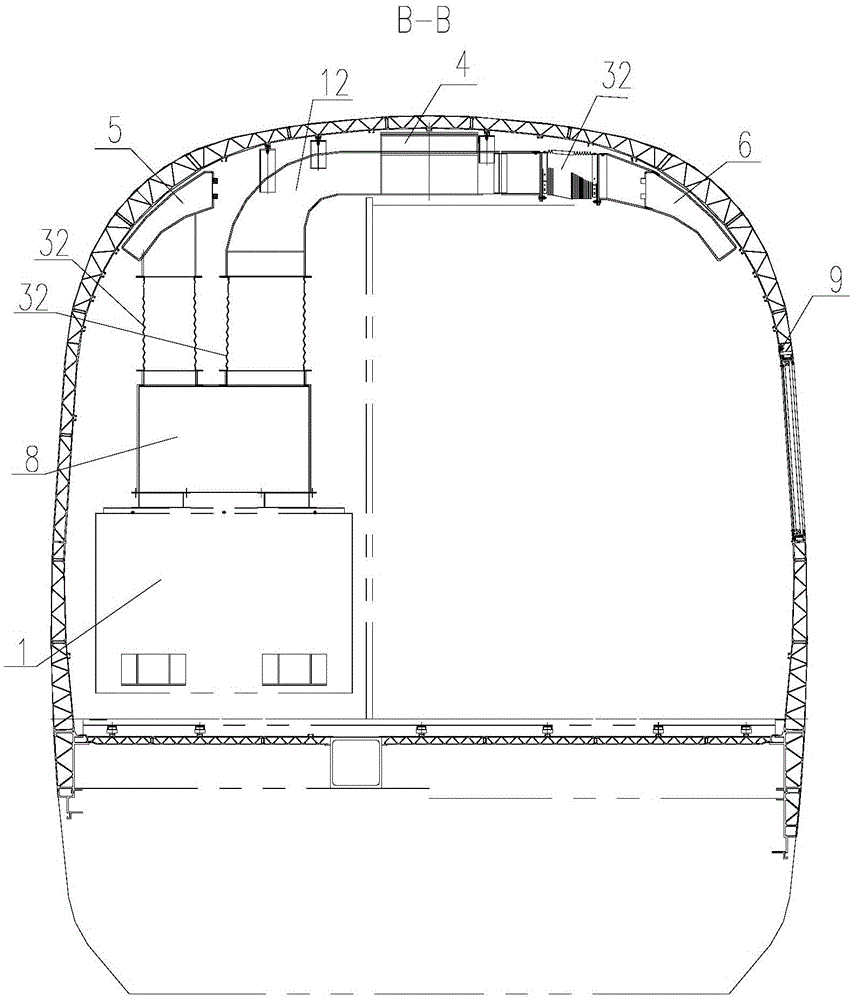

[0041] Such as figure 1 As shown, the air-conditioning duct system of the high-speed EMU includes an air-conditioning unit. In this embodiment, the air-conditioning unit is a split structure, including an indoor unit 1 and an outdoor unit (not shown in the figure), and the outdoor unit is hung below. The unit 1 is installed at one end of the compartment 2, and the indoor unit 1 and the outdoor unit are connected through refrigerant pipelines. The air-conditioning unit adopts a split structure, which can shorten the length of the air duct, thereby reducing the total weight of the air duct, and meeting the higher requirements of higher-speed EMUs for lightweight vehicles. At the same time, the shortening of the air duct can also make greater use of the cooling capacity, reduce the loss of cooling capacity caused by the excessive length of the air duct, and improve the cooling efficiency of the whole machine.

[0042] The air outlet of the indoor unit 1 is connected with the air...

Embodiment 2

[0058] The difference from Embodiment 1 is that a useful air duct is provided between the air outlet of the indoor unit 1 of the air conditioner unit and the middle ceiling air supply duct 4, the first side ceiling air supply duct 5 and the second side ceiling air supply duct 6. There is only one air volume distribution device for distributing the air volume of each air duct at the same time.

[0059] The air volume splitting device can be a plurality of deflectors arranged in the air mixing box 8, for simultaneously distributing the middle top air supply duct 4, one side top air supply duct 5 and two side top air supply ducts 6 air volume, at this time, the air supply mixing box 8 has three air outlets, respectively connected to the middle top air supply duct 4, one side top air supply duct 5 and two side top air supply ducts 6.

Embodiment 3

[0061] The difference from Embodiment 2 is that the air supply mixing box 8 has only one air outlet, and after passing through an intermediate air duct, the air volume splitter is arranged on the top of the intermediate air duct, and the air volume splitter is also a plurality of deflectors, It is used to distribute the air volume of the middle ceiling air supply duct 4, the first side ceiling air supply duct 5 and the second side ceiling air supply duct 6 at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com