Makrolon composite material and lamp

A technology of polycarbonate and composite materials, which is applied in the field of lamps and polycarbonate composite materials, can solve problems such as lamp failure, transparent lampshade cracking, and transparent lampshade large internal stress, so as to prevent stress cracking, reduce internal stress, increase The effect of high force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

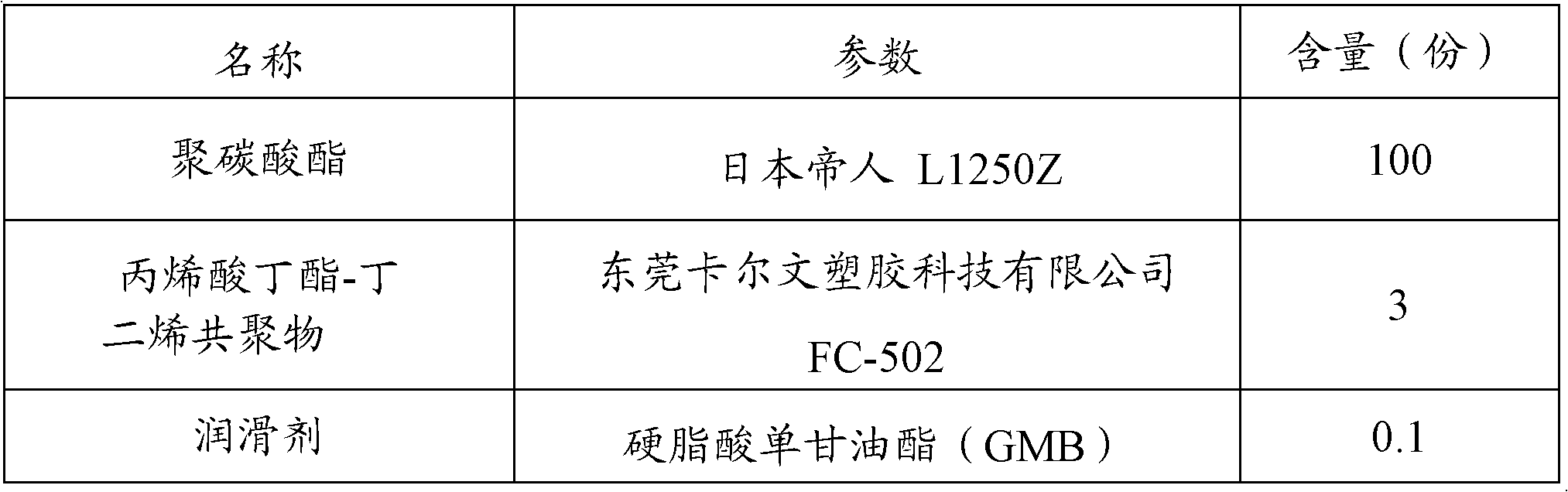

[0028] Prepare materials according to the group distribution ratio in the following table:

[0029]

[0030] Weigh each component according to the data in the above table, mix them uniformly, extrude and granulate, and obtain the polycarbonate composite material. In this embodiment, the polycarbonate, butyl acrylate-butadiene copolymer and lubricant are stirred evenly and fully mixed, then dried at 110°C to 125°C for 2 hours to 3.5 hours, and then injection molded into Transparent shade for lamps. The transparent lampshade is a long tube with an elliptical cross section, the major axis is 62.2 mm, the minor axis is 34.2 mm, the wall thickness is 2.0 mm, and the tube length is 1190 mm.

Embodiment 2

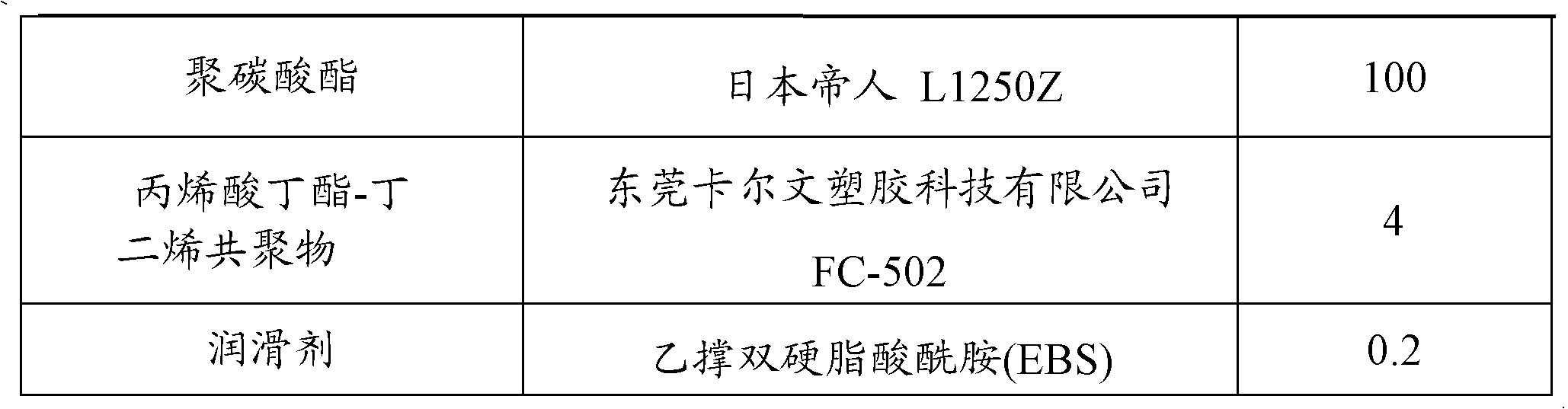

[0032] Prepare materials according to the group distribution ratio in the following table:

[0033]

[0034]

[0035] Weigh each component according to the data in the above table, mix them uniformly, extrude and granulate, and obtain the polycarbonate composite material. In this embodiment, the polycarbonate, butyl acrylate-butadiene copolymer and lubricant are stirred evenly and fully mixed, then dried at 110°C to 125°C for 2 hours to 3.5 hours, and then injection molded into Transparent shade for lamps. The transparent lampshade is a long tube with an elliptical cross section, the major axis is 62.2 mm, the minor axis is 34.2 mm, the wall thickness is 2.0 mm, and the tube length is 1190 mm.

Embodiment 3

[0037] Prepare materials according to the group distribution ratio in the following table:

[0038]

[0039] Weigh each component according to the data in the above table, mix them uniformly, extrude and granulate, and obtain the polycarbonate composite material. In this embodiment, the polycarbonate, butyl acrylate-butadiene copolymer and lubricant are stirred evenly and fully mixed, then dried at 110°C to 125°C for 2 hours to 3.5 hours, and then injection molded into Transparent shade for lamps. The transparent lampshade is a long tube with an elliptical cross section, the major axis is 62.2 mm, the minor axis is 34.2 mm, the wall thickness is 2.0 mm, and the tube length is 1190 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com