Pickling technology of removing oxide scales on carbon steel hot-rolled plate

A technology for iron oxide scale and hot-rolled sheet, which is applied to the pickling technology of carbon steel hot-rolled sheet and strip, and the pickling process field of removing scale of carbon steel hot-rolled sheet and strip, can solve the problem of poor surface quality of pickling sheet and strip, Difficulty cleaning acid sludge, slow pickling speed, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

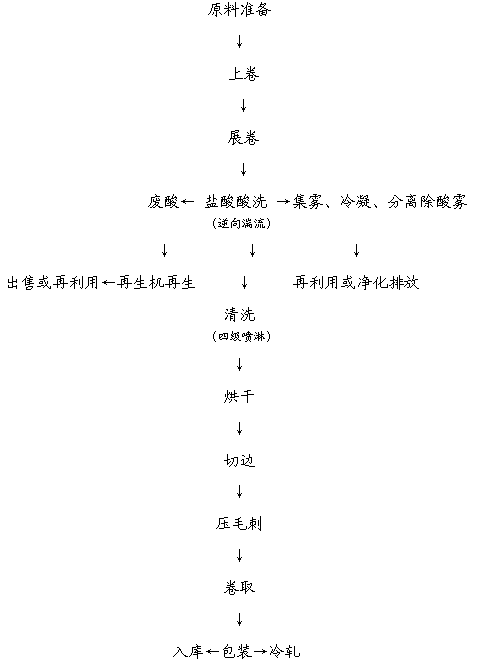

[0023] A pickling process for removing oxide scales from carbon steel hot-rolled strips is as follows: See attached drawing.

[0024] The effect of adopting the new pickling process:

[0025] 1. The pickling process has been greatly improved

[0026] The hydrochloric acid pickling process adopts advanced reverse turbulence technology, acid regeneration technology and acid mist purification technology, so that waste acid and condensed acid can be recycled and reused, and the consumption of hydrochloric acid is reduced by 70-80%.

[0027] 2. Major breakthroughs have been made in environmental protection issues

[0028] Since the regeneration of waste acid and the recycling of condensed acid are realized, the problem of environmental pollution caused by waste acid and acid mist in the metallurgical industry is fundamentally solved.

[0029] 3. Fast pickling speed with hydrochloric acid

[0030] Hydrochloric acid pickling is almost twice the speed of sulfuric acid pickling, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com