A construction method of high-pressure rotary spraying hollow reinforced pipe pile and high-pressure rotary sprayed hollow reinforced pipe pile

A technology of high-pressure rotary grouting piles and high-pressure rotary grouting, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of low overall strength of steel pipe piles, poor bonding effect of steel pipes and rotary grouting bodies, etc., and achieve construction The method is simple and efficient, saves the amount of grouting engineering in the later stage, and has the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

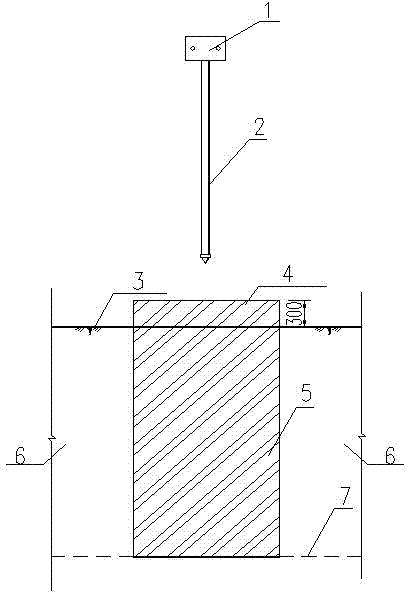

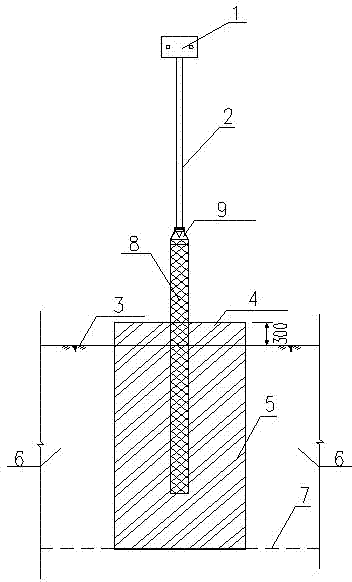

[0034] A construction method of high-pressure rotary grouting steel pipe piles, taking Jiangsu Liyang Pumped Storage Power Station as an example, the homogeneous earth dam crest elevation of the reservoir under the power station is 24.4m, the reservoir bottom elevation is -2.0m, and the normal storage level elevation is 19.0m , dead water elevation 0m.

[0035] The geological conditions of the dam foundation are extremely complex, with the thickness of silty clay in the upper part ranging from 2.0 to 5.0m, the thickness of silty clay ranging from 0 to 8.0m, and the thickness of sand, pebble and gravel layer from 2.20 to 5.50m. The silty soil is distributed at an elevation of 7.0-15.0m, located below the water level of the reservoir, and the silty clay is thicker in the area around 350m long on the north side of the homogeneous earth dam, which is 3-8m.

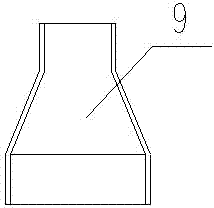

[0036] Considering factors such as the tight construction period and complex stratum conditions at the site, the constructio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com