Device and method for operating a hand-held working apparatus

A working instrument and hand-held technology, which is applied in the field of operation of hand-held working instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

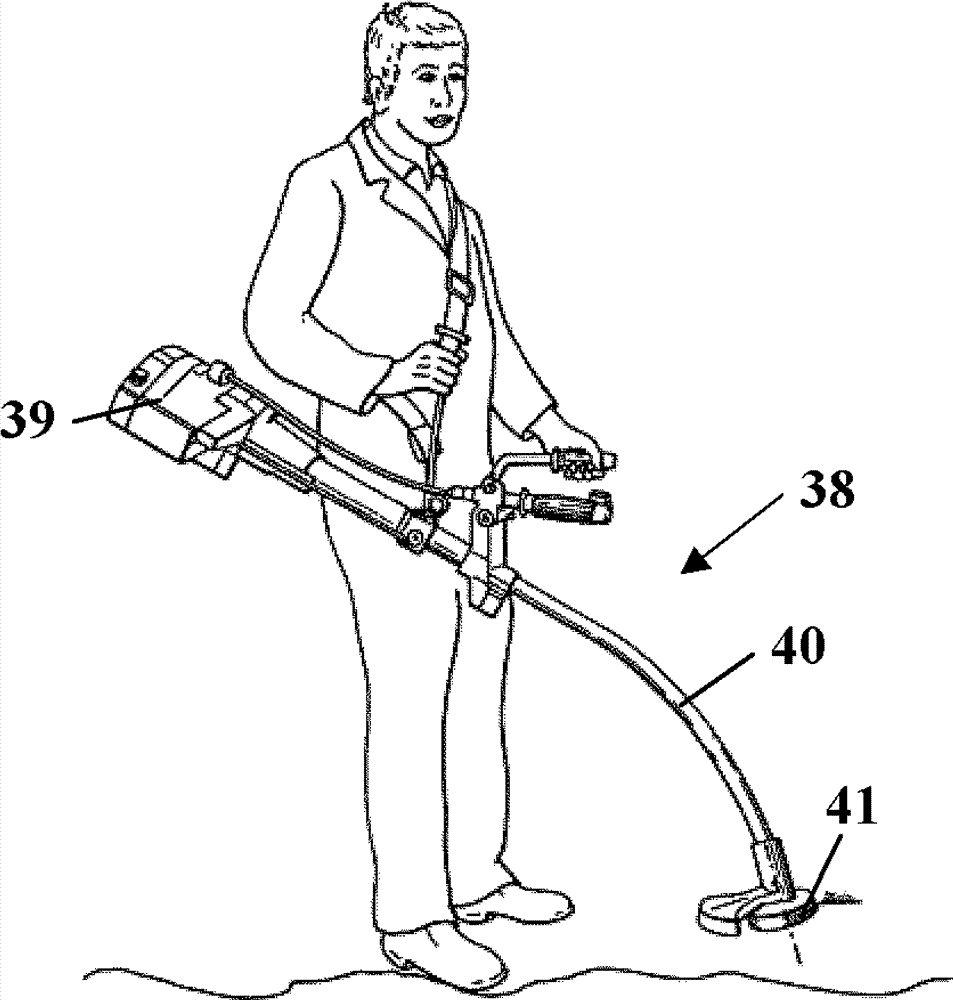

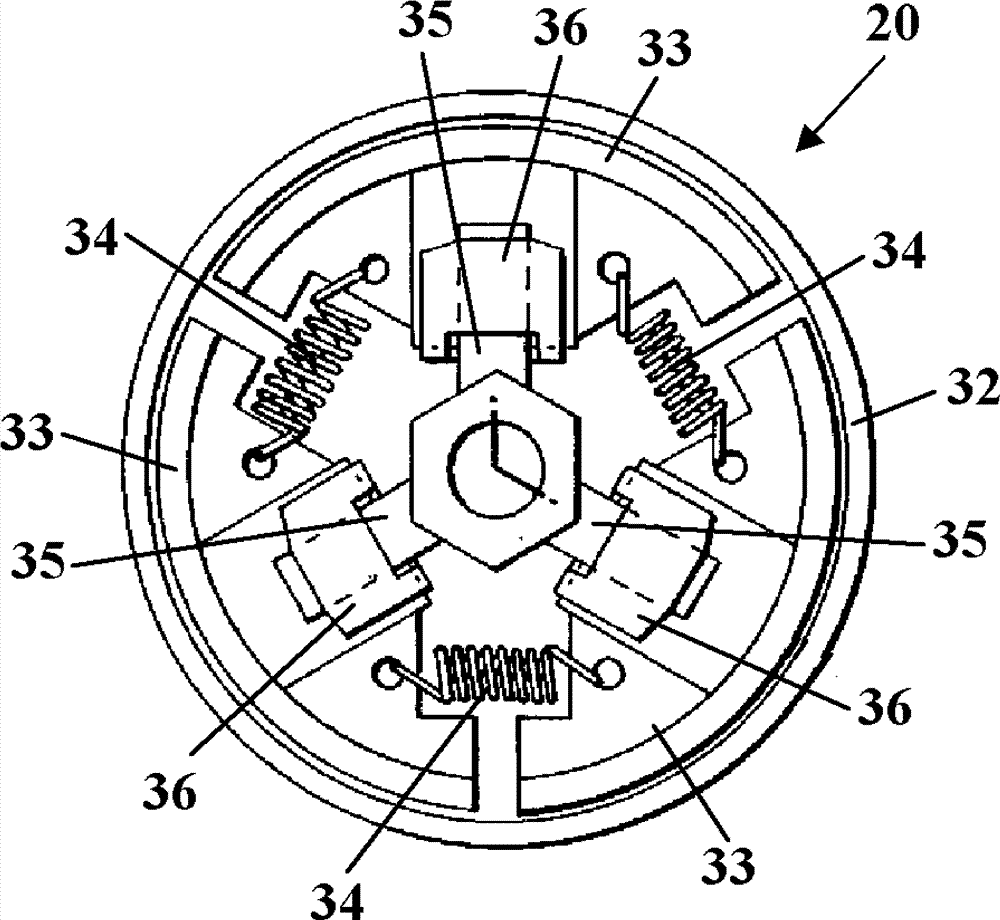

[0025] figure 1 A cutting machine 1 is shown as an example for a hand-held power tool. The cutter 1 has a housing 2 to which a rear handle 3 and a handle tube 4 are fastened via anti-vibration elements, not shown. A throttle lever 17 and a throttle lever lock 18 are arranged on the rear handle 3 . Arranged in the housing 2 are the figure 1 The internal combustion engine 9 shown schematically in FIG. 1 is constructed as a single-cylinder two-stroke engine. Protruding from the casing 2 is a starting handle 6, through which the starting handle can be manipulated in the figure 2 The starting device 23 for the internal combustion engine 9 is shown in FIG. A bracket 5 is arranged on the housing 2 , and a protective cover 7 is arranged at its forwardly protruding end. The protective hood 7 overlaps the cutting disk 8 , which is rotatably mounted on the carrier 5 . The cutting disc 8 is driven by the internal combustion engine 9 via the figure 2 Driven by a drive belt 22 show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com