Preparation method for halogen mixed with cadmium telluride, thin film solar cell of halogen mixed with cadmium telluride and preparation method thereof

A solar cell and cadmium telluride technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problems of difficult control of halogen doping concentration, hazards to operators and the environment, and poor uniformity of cadmium halide, so as to reduce the operating process and experimental equipment, reduce production costs, and fully respond to the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The first aspect - the preparation method of halogen-doped cadmium telluride

[0027] First, the preparation method of halogen-doped cadmium telluride according to the present invention is explained.

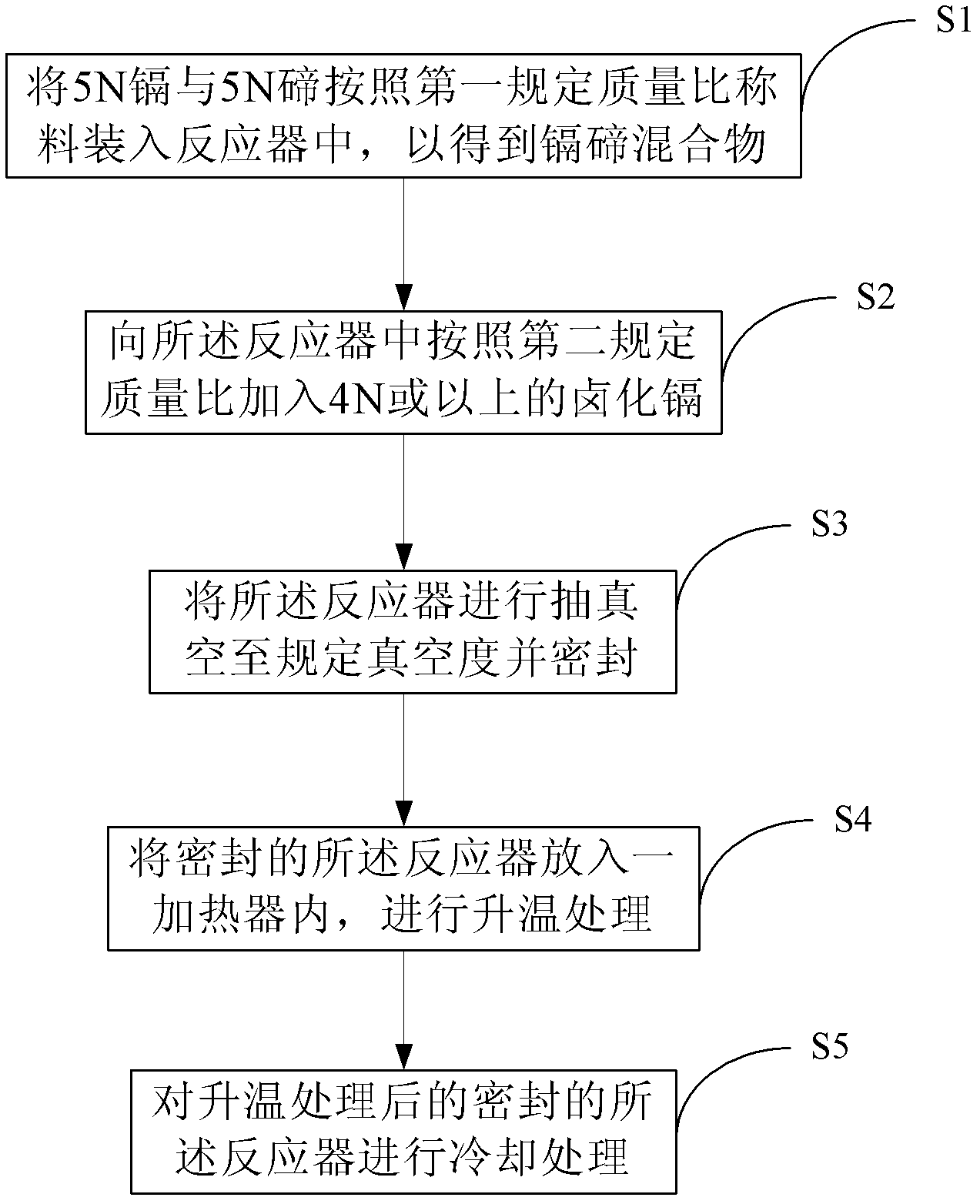

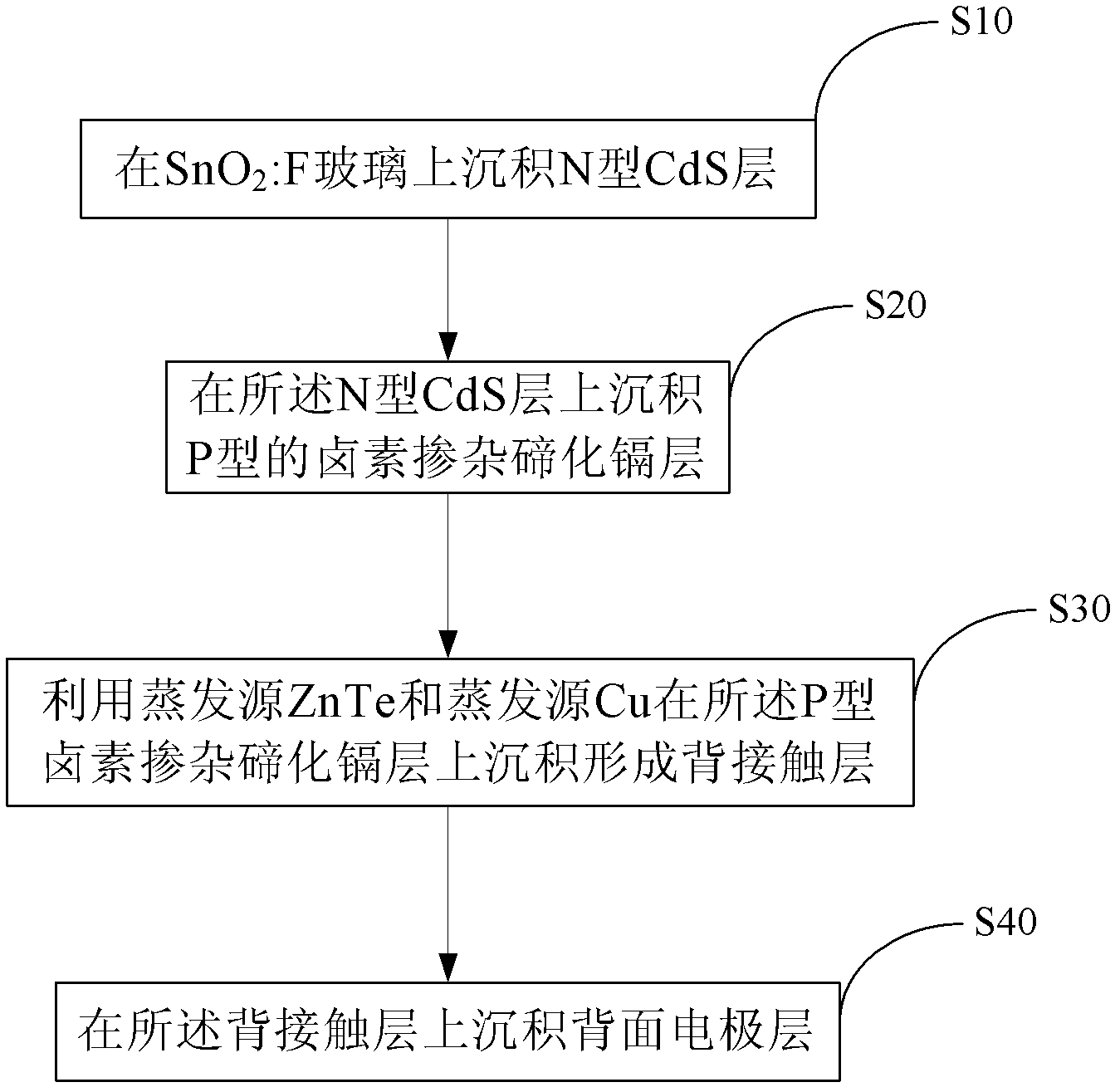

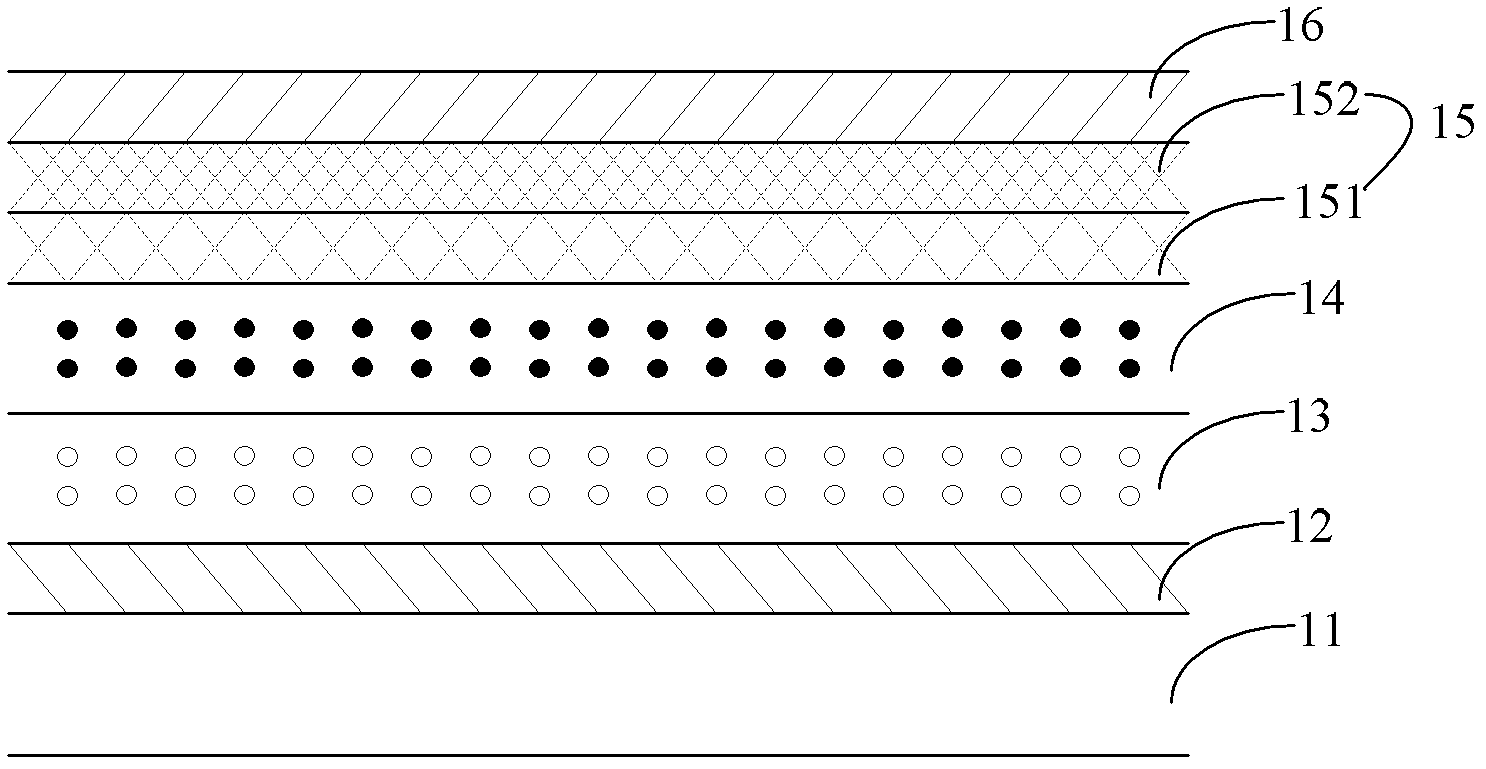

[0028] Such as figure 1 As shown, the preparation method of halogen-doped cadmium telluride according to the present invention includes the steps of: weighing 5N cadmium and 5N tellurium into a reactor according to a first prescribed mass ratio to obtain a cadmium-tellurium mixture (step S1), wherein , the first prescribed mass ratio is the mass ratio between the 5N cadmium and the 5N tellurium; adding 4N or more cadmium halides to the reactor according to the second prescribed mass ratio (step S2), the The second prescribed mass ratio is the mass ratio between the cadmium halide and the cadmium tellurium mixture; vacuumize the reactor to a prescribed vacuum degree and seal it (step S3); put the sealed reactor into In a heater, a temperature rise treatment is performed ...

Embodiment 1

[0038] (1) First, 500 g of 5N cadmium and 5N tellurium are weighed in a mass ratio of 1:1 and loaded into a reactor to obtain a cadmium-tellurium mixture;

[0039] (2) according to the mass ratio of cadmium chloride and cadmium tellurium mixture, be 15mg / kg to add 4N cadmium chloride in above-mentioned reactor;

[0040] (3) vacuumize the reactor after the above-mentioned charging to make its vacuum degree reach 10 -2 Pa and sealed;

[0041] (4) The heating process is as follows: when the heater heats up to 200°C, put the sealed reactor into it, keep it warm for 10 minutes, then raise the temperature to 700°C at a heating rate of 13°C / min, keep it warm for 15 minutes, and then heat it at a heating rate of 3°C / min. min to raise the temperature to 1150°C and hold for 10 minutes;

[0042] (5) The cooling process is as follows: the reactor is taken out from the above-mentioned heater at a speed of 1 mm / h, and cooled at room temperature;

[0043] (6) Take out the sample from the ...

Embodiment 2

[0045] (1) First, 450 g of 5N cadmium and 5N tellurium are weighed in a mass ratio of 1: 1.13 and loaded into a reactor to obtain a cadmium-tellurium mixture;

[0046] (2) according to the mass ratio of cadmium chloride and cadmium tellurium mixture, be 50mg / kg to add 5N cadmium chloride in above-mentioned reactor;

[0047] (3) vacuumize the reactor after the above-mentioned charging to make its vacuum degree reach 10 -2 Pa and sealed;

[0048] (4) The heating process is as follows: when the heater heats up to 200°C, put the sealed reactor into it, keep it warm for 30 minutes, then raise the temperature to 800°C at a heating rate of 13°C / min, keep it for 30 minutes, and then heat it at a heating rate of 5°C / min. min to raise the temperature to 1200°C and hold for 10 minutes;

[0049] (5) The cooling process is as follows: the charging reactor is directly taken out from the heater as a whole, and cooled at room temperature;

[0050] (6) The sample is taken out from the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com