Bottle hole reef in frame structure

A frame structure and cave technology, applied in the field of artificial reefs, can solve the problems of difficulty in producing a dense number of caves, no effective caves, and construction costs of fish reefs, and achieve the effects of light weight, small water resistance, and convenient storage and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

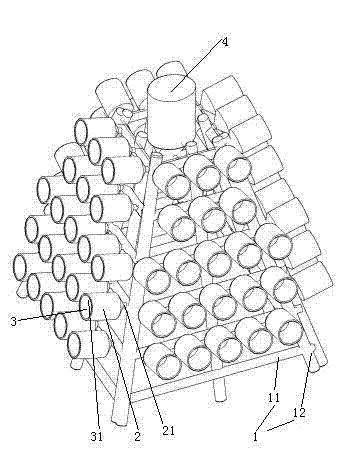

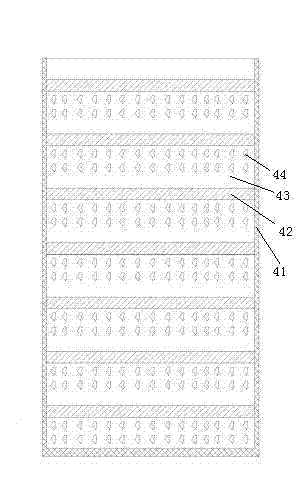

[0024] Embodiment one, see figure 1 , a bottle hole reef with a framework structure, including cave attachments 1 . The cave attachment 1 is a quadrangular truss-shaped frame built with horizontal rods 11 and vertical rods 12 . The horizontal bar material 11 and the vertical bar material 12 are round bars. Horizontal bar material 11 and vertical bar material 12 are the bar (comprising pipe) that abandons. The horizontal bar material 11 and the vertical bar material 12 are made of plastic material. The cave attachment 1 is constructed by a plastic tube.

[0025] Several first plastic bottles 2 are densely covered on the four sides of the cave attachment 1 . The first plastic bottle 2 is a collected waste plastic bottle. The bottleneck 21 of the first plastic bottle has thread (thread is not drawn in the figure). The inner cavity of the first plastic bottle 2 forms a cavity 3 . The bottom of the first plastic bottle 2 is removed so that the bottom end is open. The open b...

Embodiment 2

[0030] Embodiment two, the difference with embodiment one is:

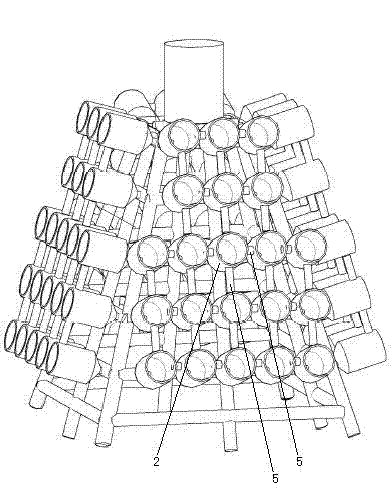

[0031] see image 3 , also includes a number of reinforcing rods 5 . The reinforcing rod 5 is a flexible body. The reinforcing rods 5 are staggered into a network structure. The first plastic bottle 2 is fixed on the nodes between the reinforcing rods. The first plastic bottle 2 is connected with a first float (the first float is fixed inside the first plastic bottle, not shown in the figure). The first float can float the first plastic bottle 2 .

[0032] see Figure 4 , the reinforcing rod 5 is provided with a sealing cavity 51 extending along the length direction of the reinforcing rod, and the sealing cavity 51 is filled with gas. Reinforcing bar 5 can rely on the buoyancy that self suffers to float.

Embodiment 3

[0033] Embodiment three, the difference with embodiment two is:

[0034] see Figure 5 , also includes a connecting rod 7 passing through the mouth 21 of the first plastic bottle and connected to the cave attachment 1. The connecting rod 7 is provided with a first threaded sleeve 71 and a second threaded sleeve 72 . The free end of the connecting rod 7 is provided with threads. Both the first threaded sleeve 71 and the connecting rod 7 are provided with alignable through holes on one end of the cave attachment. The first threaded sleeve 71 is sheathed on the connecting rod 7 and fixed together with the connecting rod 7 after passing through the through hole through the cable tie 9 . The first plastic bottle 2 is screwed on the first threaded sleeve 71 . The first float 6 is fixed on the inner surface of the first plastic bottle 2 .

[0035] The second threaded sleeve 72 is screwed on the free end of the connecting rod 7 . The second plastic bottle 8 is screwed on the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com