Dry transporting and dry stockpiling method of Bayer red mud

A technology based on Bayer red mud and Bayer red, which is applied in transportation and packaging, dehydration/drying/thickened sludge treatment, loading/unloading, etc., and can solve problems such as unfavorable re-cultivation, unable to recycle attached liquid, and great impact on the surrounding environment , to achieve the effect of reducing vehicle injuries, reducing insufficient capital investment, and improving the safe operation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

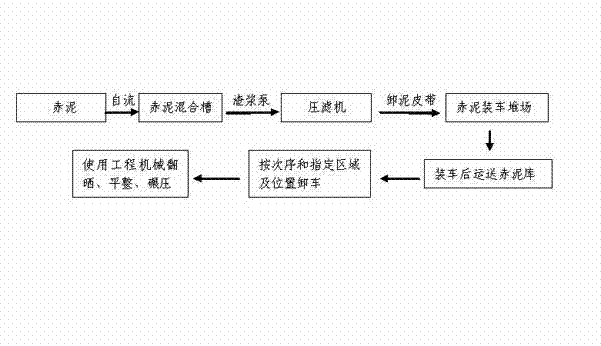

[0053] A Bayer red mud dry transportation and dry storage method, characterized in that: the waste red mud generated in the process of refining alumina from bauxite flows into the red mud mixing tank automatically, and the red mud in the red mud mixing tank passes through the slag The slurry pump is transported to the filter press, and the filtered red mud is transported to the red mud loading yard through the mud unloading belt. Leveling and rolling the red mud in the red mud storage.

[0054] The Bayer red mud dry transportation and dry storage method is characterized in that it is carried out according to the following steps:

[0055] Step 1): The waste red mud produced in the process of extracting alumina from bauxite is washed and then flows into the red mud mixing tank;

[0056] Step 2): transport the red mud in the red mud mixing tank to the filter press through the slurry pump;

[0057] Step 3): filter the red mud through a filter press;

[0058] Step 4): The filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com