Antibacterial touch panel and manufacturing method thereof

A technology for a touch panel and a manufacturing method, applied in the directions of instruments, electrical digital data processing, input/output process of data processing, etc., can solve problems such as thickness of antibacterial coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

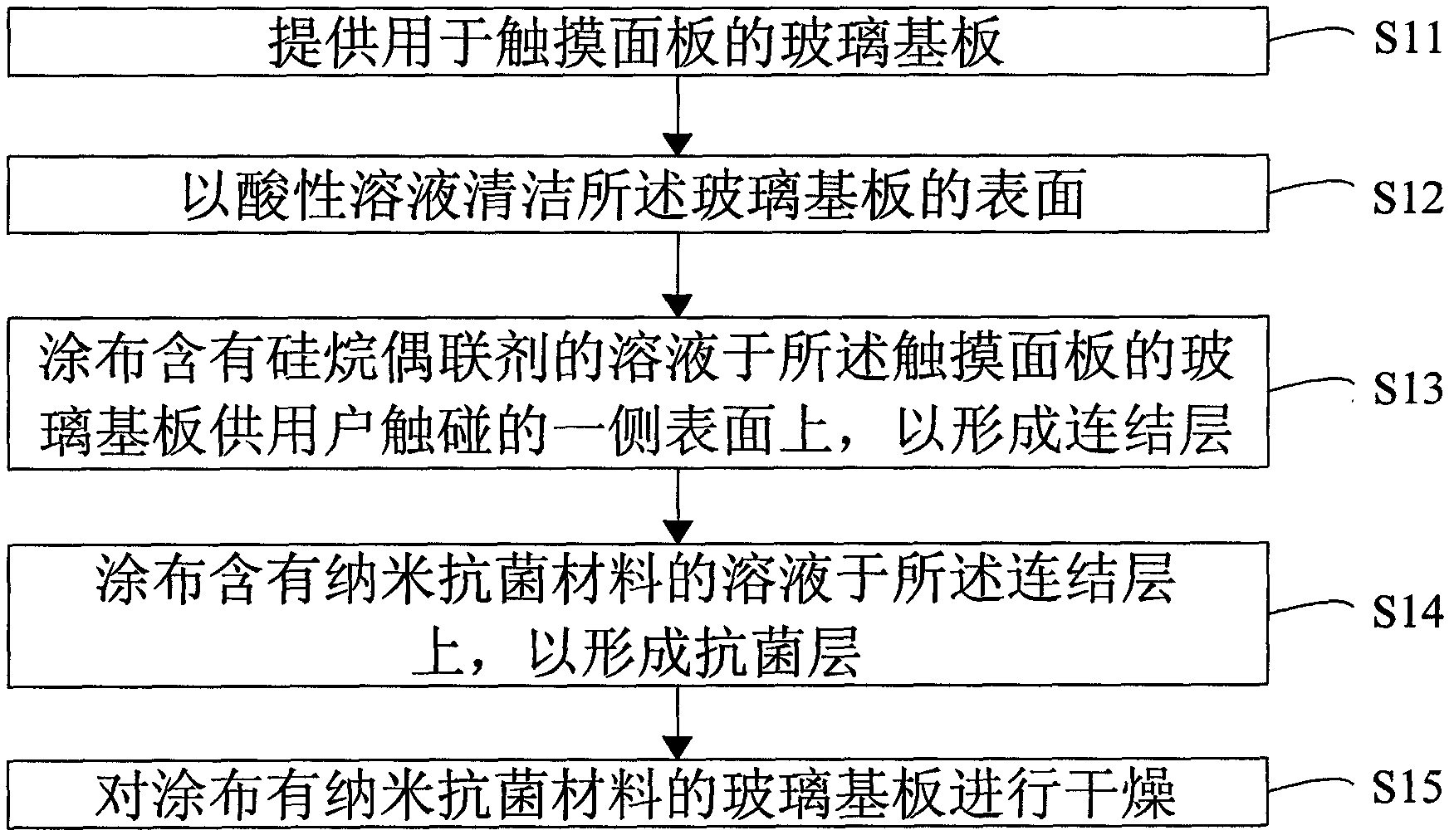

Method used

Image

Examples

Embodiment 1

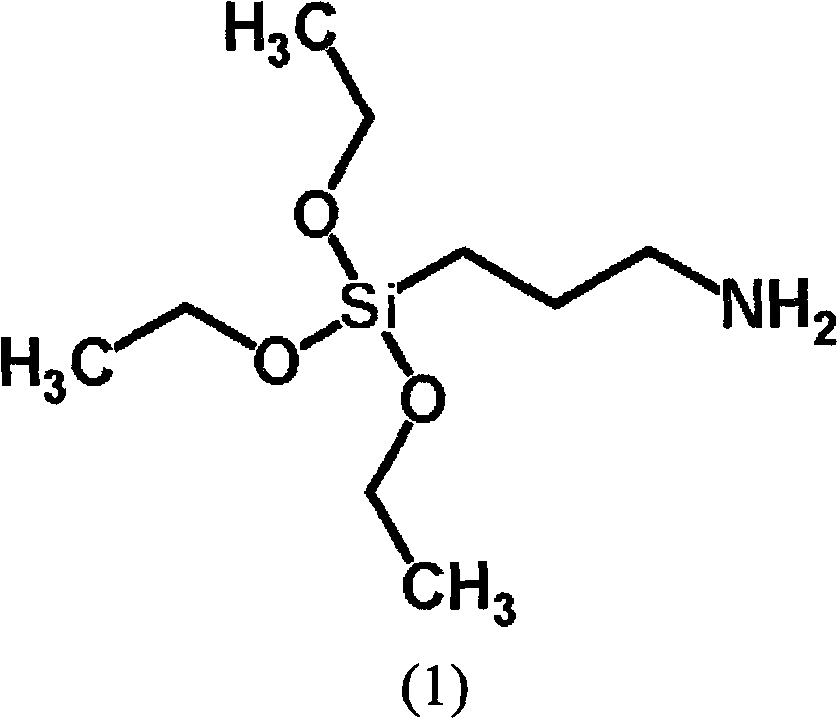

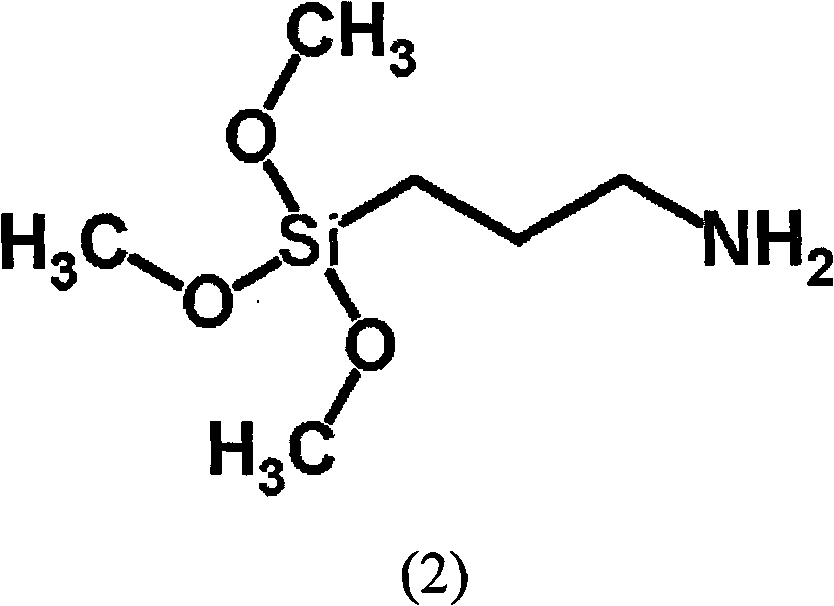

[0046] A specific embodiment of the present invention, first soak the glass substrate of the touch panel in 18M sulfuric acid solution for 1 minute, then remove the sulfuric acid solution remaining on the surface of the glass substrate with deionized water; soak the cleaned glass substrate in a concentration of 1 % of the silane coupling agent solution containing 3-aminopropyltriethoxysilane, and react at room temperature for 30-60 minutes, after the reaction, remove the silane coupling agent remaining on the surface of the glass substrate with deionized water and ethanol ; Soak the reacted glass substrate in a solution containing 1000ppm nano-silver, react at room temperature for 12-24 hours, remove the solution containing nano-silver remaining on the surface of the glass substrate with deionized water and ethanol after the reaction, and finally at room temperature Drying is carried out to obtain a highly transparent touch panel with antibacterial properties. The antibacteria...

Embodiment approach

[0048]Another specific embodiment of the present invention, first soak the glass substrate of the touch panel in 18M sulfuric acid solution for 1 minute, then remove the sulfuric acid solution remaining on the surface of the glass substrate with deionized water; soak the cleaned glass substrate in the concentration 0.5% solution of silane coupling agent containing 3-aminopropyltriethoxysilane, and react at room temperature for 10-30 minutes, after the reaction, remove the silane coupling remaining on the surface of the glass substrate with deionized water and ethanol agent, and heat-treat it, the heat-treatment temperature is 80°C, and the treatment time is 30-60 minutes; soak the reacted glass substrate in a solution containing 500ppm nano-silver, and react at room temperature for 1-4 hours, after the reaction The solution containing nano-silver remaining on the surface of the glass substrate is removed with deionized water and ethanol, and finally it is heat-treated at 80°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com