Method of reducing the rate of depletion of basicity of lubricating oil composition in use in engine

A lubricating oil composition, engine technology, applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problem of not increasing the ash content

Active Publication Date: 2013-06-26

INFINEUM INT LTD

View PDF17 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It is also important that the ash content does not increase, since too high a sulphated ash content can lead to increased deposits on the pistons and exhaust gas circuit (including heat recovery system and aftertreatment device)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

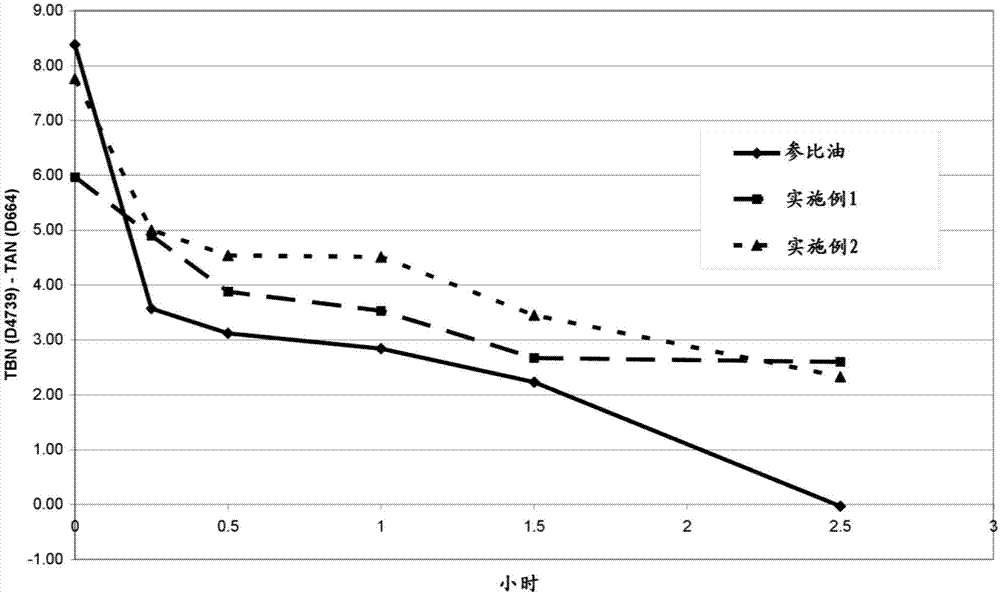

[0121] It is important to introduce alkalinity into the lubricating oil composition for as long as possible. It is also important that the TBN and TAN levels intersect for as long as possible. These measures all ensure longer oil life and better engine protection over a longer period.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

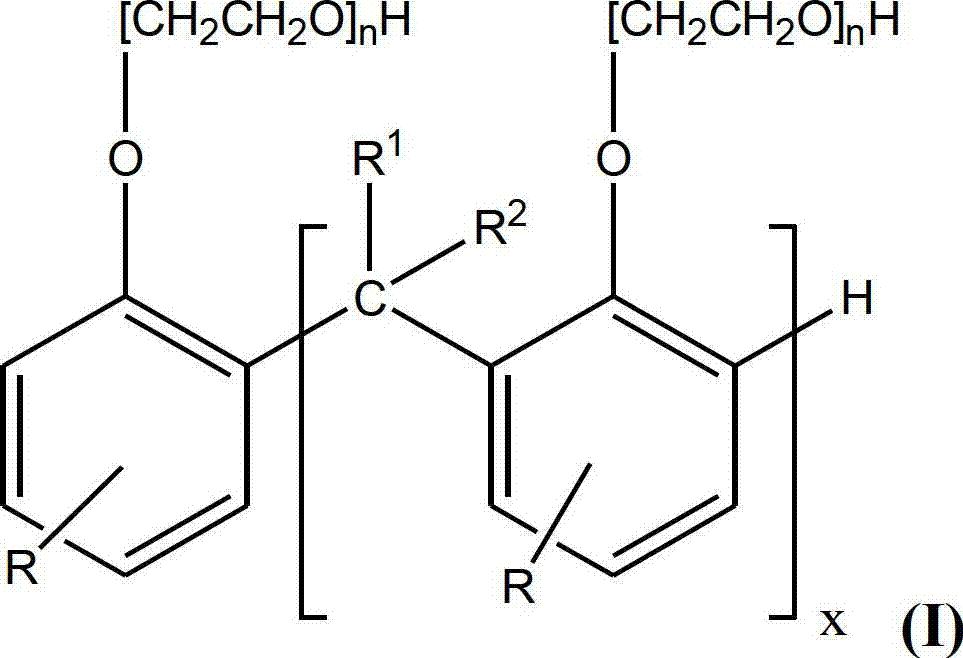

Disclosed is a method of reducing the rate of depletion of basicity (as determined by ASTM D2896) of a lubricating oil composition in use in an engine. The lubricating oil composition includes at least one overbased alkali or alkaline earth metal detergent. The method comprises adding to the lubricating oil composition one or more compounds of Formula (I): (see formula I) wherein: x is 1 to 50, preferably 1 to 40, more preferably 1 to 30; R1 and R2 are H, hydrocarbyl groups having 1 to 12 carbon atoms, or hydrocarbyl groups having 1 to 12 carbon atoms and at least one heteroatom; R is a hydrocarbyl group having 9 to 100, preferably 9 to 70, most preferably, 9 to 50, carbon atoms; and n is 0 to 10, or alkaline earth metal salts thereof. The compounds of formula (I) are preferably methylene-bridged alkyl phenols or ethoxylated methylene-bridged alkyl phenols.

Description

field of invention [0001] The present invention relates to a method of reducing the rate of depletion of basicity (determined by ASTM D2896) of a lubricating oil composition for use in an engine, said lubricating oil composition comprising at least one oil-soluble overbased Alkaline or alkaline earth metal detergents. In particular, the present invention relates to a method of reducing the alkalinity depletion rate (as determined by ASTM D2896) of a lubricating oil composition used in an engine, without increasing the sulfated ash content (SASH) Comprising at least one oil-soluble overbased alkali metal or alkaline earth metal detergent. Preferred lubricating oil compositions are marine cylinder lubricants, trunk piston engine oils, gas engine oils or crankcase lubricating oil compositions (including passenger car engine oils and heavy duty diesel engine oils). Background of the invention [0002] The lubricating oil composition contains an oil soluble overbased detergent ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M145/20C10N30/04

CPCC10M145/18C10M145/20C10M165/00C10M2209/101C10M2219/046C10N2010/04C10N2030/52C10N2040/25C10M161/00C10N2030/04C10N2040/252C10M129/16

Inventor A·P·马施N·J·米尔内

Owner INFINEUM INT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com