Rotary electromagnet clutch mechanism

A technology of rotating electromagnet and clutch mechanism, applied in building structure, non-mechanical transmission-operated locks, door/window accessories, etc., can solve the problems of low work efficiency, reduced safety and practical performance, high power consumption, etc. To achieve the effect of simple structure, clear division of labor, and reduction of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

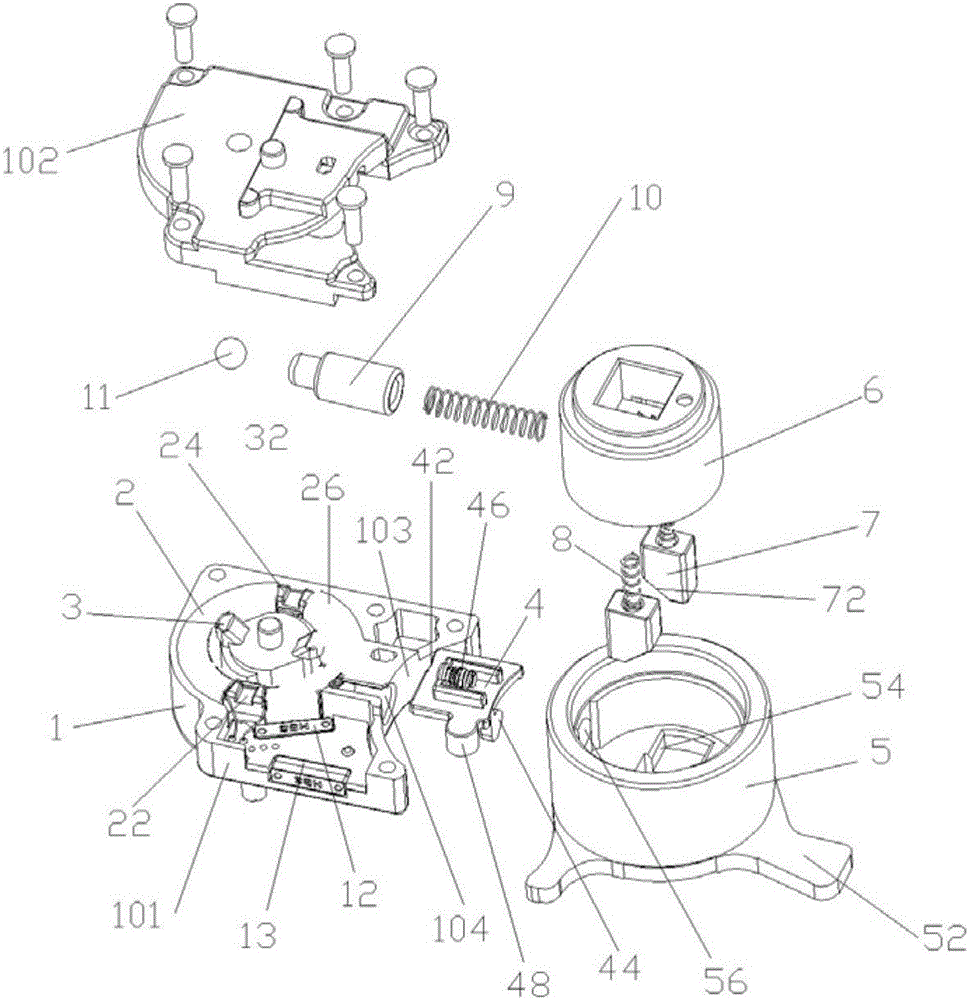

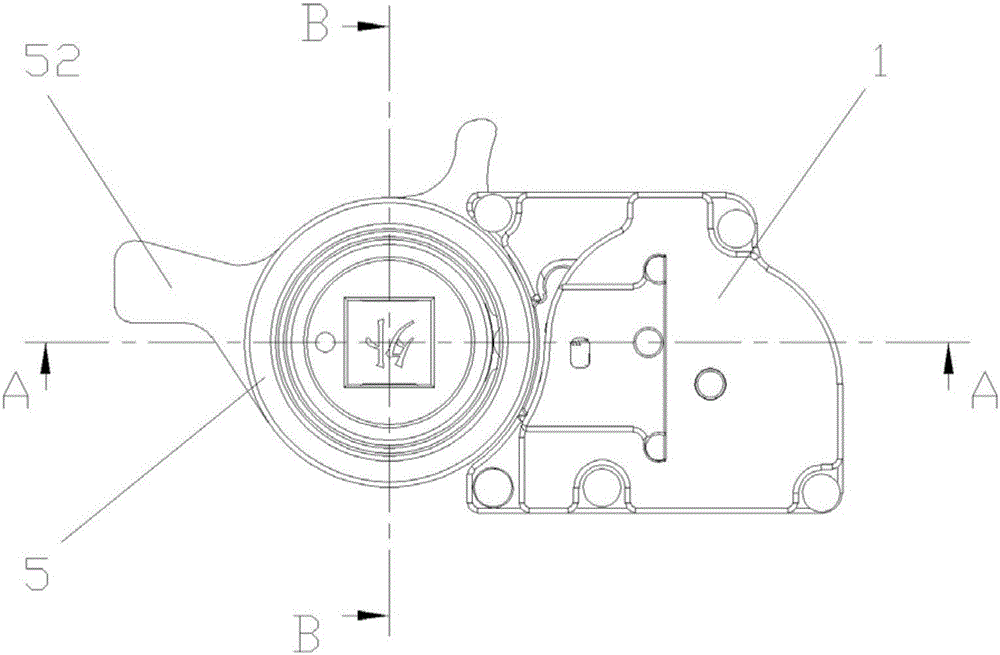

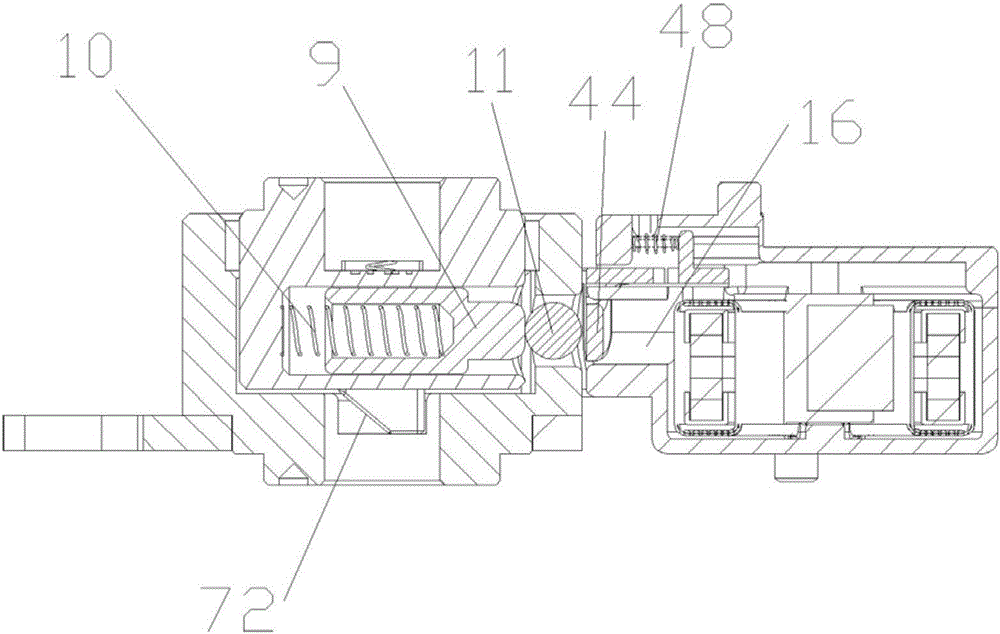

[0021] see Figure 1 to Figure 4 , the rotating electromagnet clutch mechanism, which includes a casing 1, a stator 2, a rotor 3, a clutch push plate 4, an inner handle shaft 5, an outer handle shaft 6, a clutch tooth 7, a clutch pin 9, and a steel ball 11; It is composed of a base 101 and a cover 102. The base 101 is hollow and defines a storage room with its hollow part. The stator 2, the rotor 3 and the clutch push plate 4 are installed in the storage room to form a rotating electromagnet drive servo mechanism. , The clutch pin is installed in the hole on the side of the outer handle shaft, and a spring 10 is established inside it; the steel ball is arranged between the clutch pin and the clutch push plate, and is in a free state.

[0022] The stator 2 is hollow and ring-shaped, and a through hole is formed at the center of the ring, including a stator core 22 and a winding coil 26. The stator core 22 is ring-shaped, and a diameter The clamping blocks 24 are arranged symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com