Membrane type wall structure and application thereof

A membrane-type wall and tube-type technology, applied to building components, building structures, insulation, etc., can solve the problems that high-temperature materials cannot be effectively transported, effectively utilized, and waste heat cannot be implemented, so as to facilitate repair welding maintenance, Easy maintenance and fewer failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

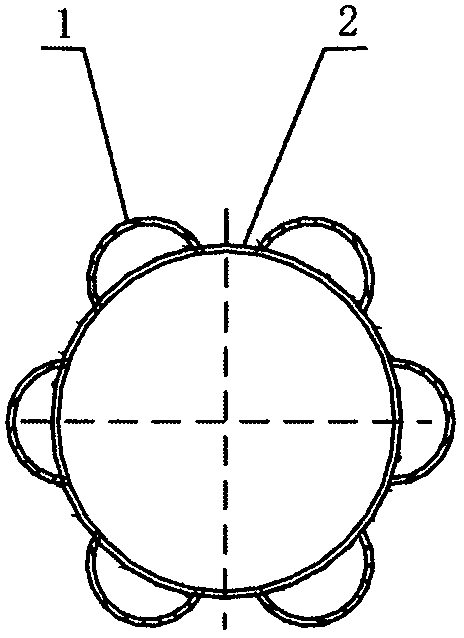

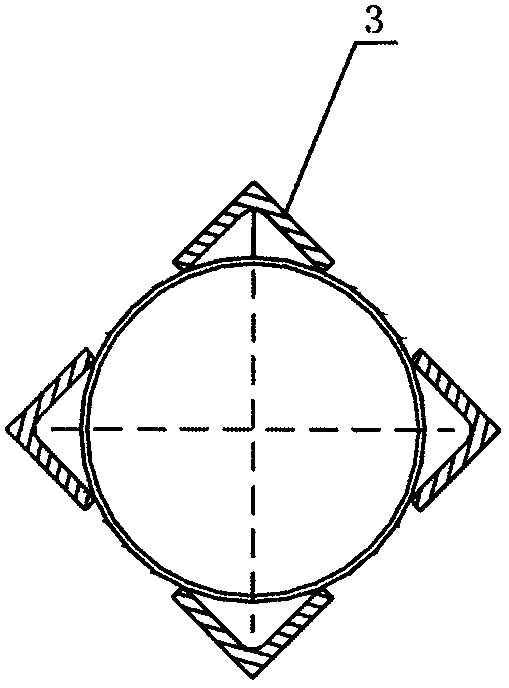

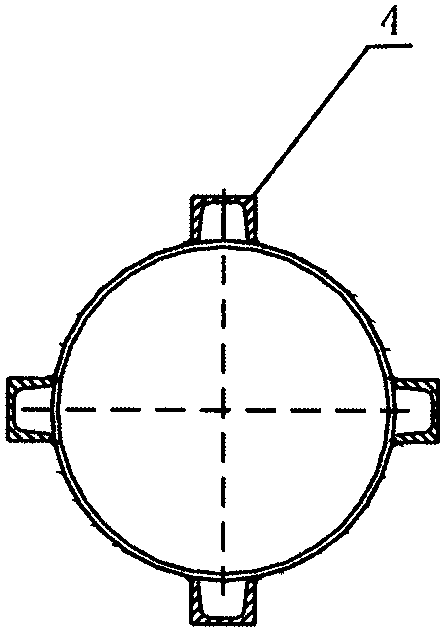

[0028] Such as Figure 1 to Figure 3 As shown, the membrane wall structure is formed by welding an arc tube structure 1 (radian<360°), an angle steel structure 3 or a channel steel structure 4 on the outer circumferential surface of a circular tube structure 2; the membrane wall structure The structure can be applied on high temperature feeding tube, high temperature ball mill and / or high temperature roller conveyor.

Embodiment 2

[0030] Such as Figure 4 to Figure 6 As shown, the membrane wall structure is formed by welding an arc tube structure 1 (radian <360°), an angle steel structure 3 or a channel steel structure 4 on multiple sides of a rectangular tube structure 5; the membrane wall structure can be Applied on high temperature feeding pipes and / or high temperature pneumatic conveyors.

Embodiment 3

[0032] Such as Figure 7 to Figure 9 As shown, the membrane wall structure is formed by welding an arc tube structure 1 (radian<360°), an angle steel structure 3 or a channel steel structure 4 on one side of a flat plate structure 6; the membrane wall structure is used as The trough of the scraper conveyor can constitute an environmentally friendly, energy-saving, and safe high-temperature scraper conveyor; Water can form a high temperature crusher. In addition, the membrane wall structure can form a new type of thermal insulation wall after being connected with a heat transfer medium as a thermal insulation panel for the wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com