Regeneration and reactivation method of coal liquefied oil hydrogenation deactivated catalyst

A technology of deactivated catalyst and hydrogenation catalyst, applied in the field of deactivated catalyst regeneration and reactivation, can solve the problem of limited recovery of hydrogenation catalyst activity, and achieve the effects of improving interaction, increasing the number, and changing the distribution of active phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0108] SiO 2 It is usually introduced as a component of the support in the preparation of the support, but the introduction of modifiers as regenerant post-treatment modifiers into regenerated catalysts has not been proposed in any patents.

[0109] The present invention adopts following technical scheme to realize the purpose of the present invention:

[0110] 1. Use a silicon-containing additive that does not contain sodium ions and deionized water (or deionized water and organic alcohol, or a mixture of deionized water and organic alcohol) to prepare an impregnating solution in a certain proportion, and the surface of the regenerated catalyst The lost Si additive is replenished.

[0111] Substantially free of sodium ions means that the content of sodium ions in the silicon-containing additive is less than 0.1 wt%. Silicon-containing additives can be selected from one or a mixture of two or more of the following: inorganic silicon-containing substances selected from silica...

Embodiment 1

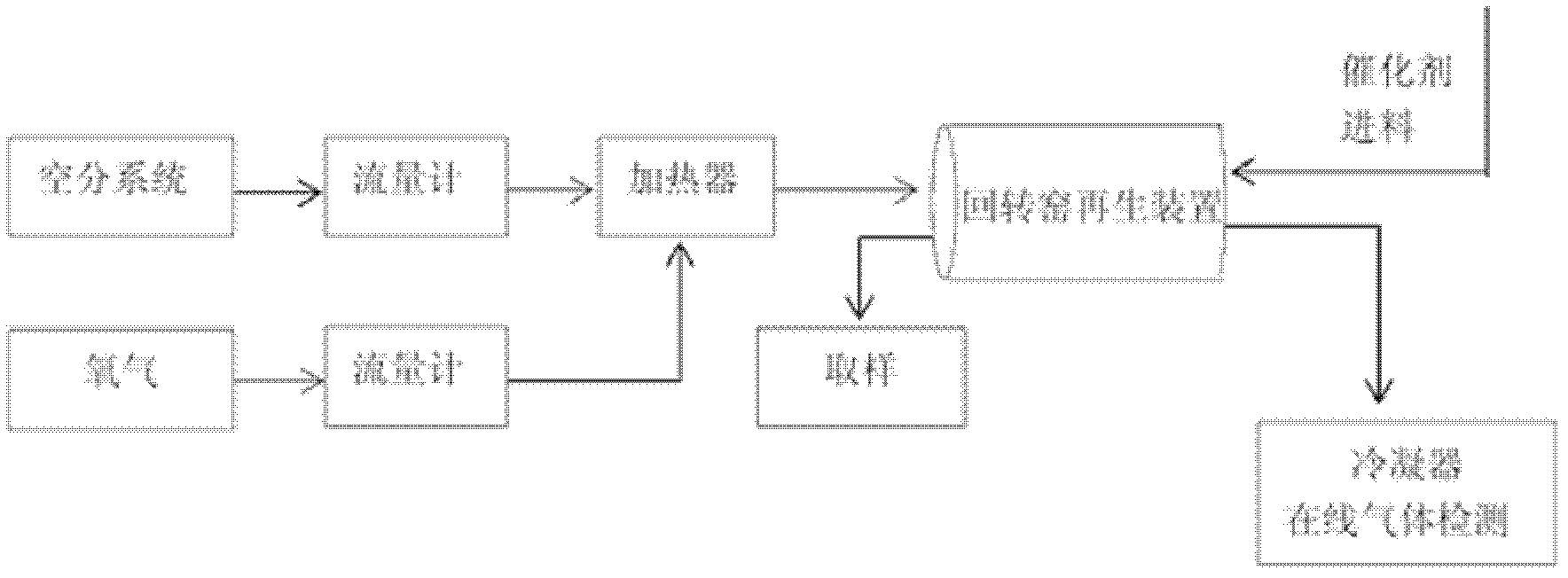

[0151] The deactivated hydrogenation catalyst operating in the coal liquefied oil unit is taken out online from the T-Star ebullating bed unit, and the hydrocarbons on the surface of the catalyst are removed through the hot nitrogen band oil, wherein the temperature of the hot nitrogen gas is 250-280 °C, and the nitrogen band The air-to-agent ratio of oil is 300-400h -1 (vol / vol), residence time 3-5 hours. The number is recorded as ST.

[0152] The following examples use the ST catalyst obtained in Example 1 to carry out regeneration and revival experiments.

Embodiment 2

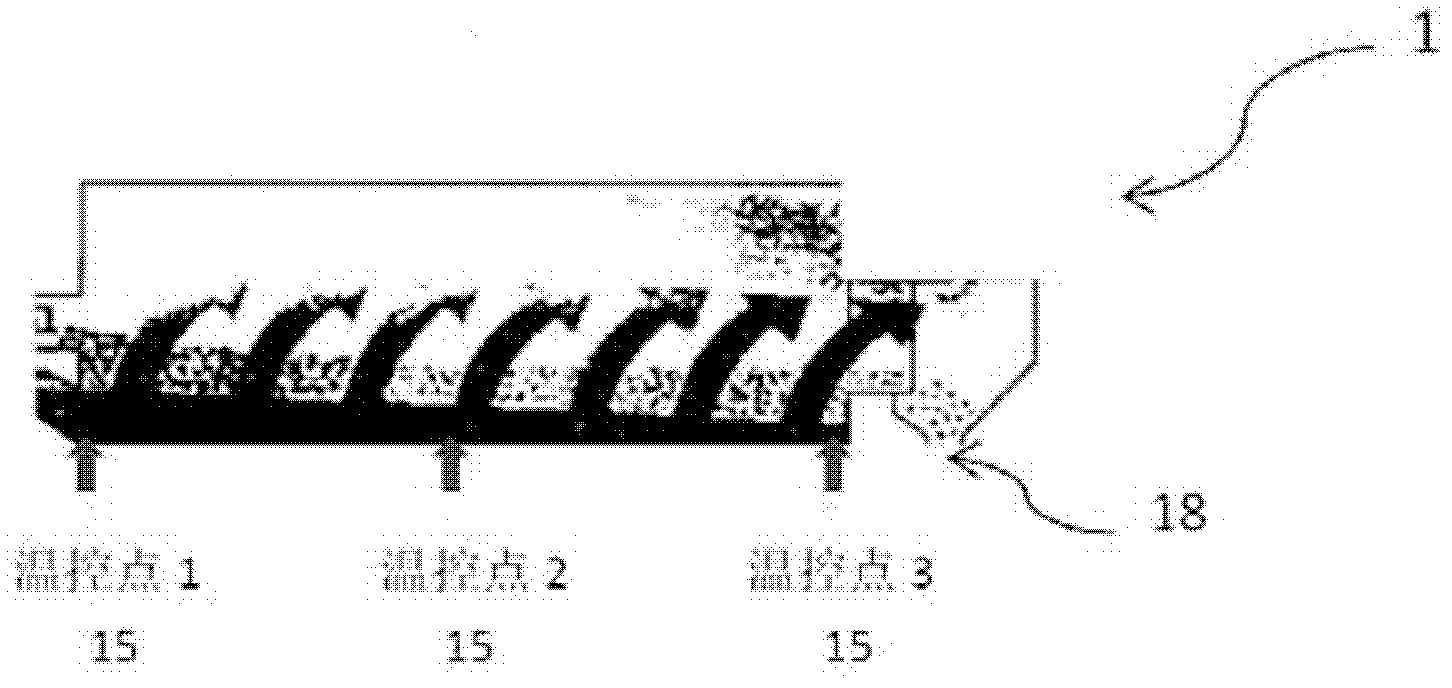

[0154] Take the catalyst ST after the hot nitrogen belt oil obtained in Example 1, and carry out the temperature-programmed regeneration of the deactivated hydrogenation catalyst through external regeneration according to the regeneration process of the deactivated hydrogenation catalyst described above, first at 250°C-350°C Most of the carbon deposits and sulfur on the surface of the deactivated catalyst are burned off, and then the temperature is programmed to rise to 450°C-470°C. The external regeneration of the deactivated catalyst is carried out by first raising the temperature and then increasing the oxygen content. Cool down to room temperature after regeneration to obtain SO catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com