Clamping method and device for cutting junction surface of semi-open thin-wall container

A thin-walled container, cutting processing technology, applied in the direction of positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems that cannot meet the requirements of dimensional accuracy, and achieve the effect of compact structure, high dimensional accuracy and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

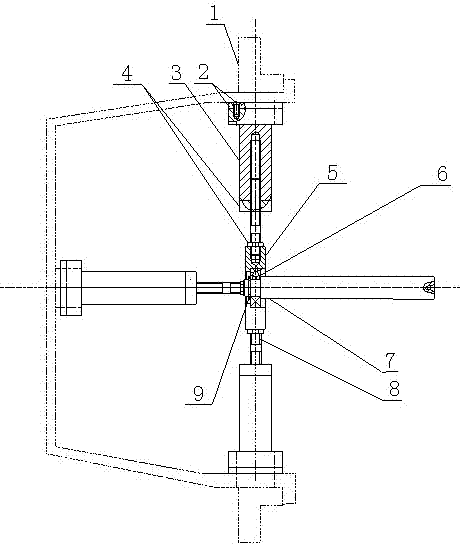

[0020] Embodiment 1: The thin-walled container workpiece is a triangular semi-open thin-walled container workpiece.

[0021] The outer jaw assembly 1 in this embodiment is a three-jaw chuck, and the radial compression head assembly 2 is divided into three groups, and each group of gaskets at the top of the compression head assembly 2 and each jaw of the outer jaw assembly 1 The positions are evenly distributed on the circumference in one-to-one correspondence.

[0022] The clamping method in this embodiment includes the following steps: when starting to process, the workpiece is first placed on the three-jaw chuck of the machine tool, the outer surface of the workpiece is in contact with the three-jaw chuck of the machine tool, and the machine tool tailstock is manipulated to drive the machine tool assembled on the machine tool tailstock. The movable top follows the tailstock shaft close to the center hole at one end of the central shaft 7, and adjusts the axial compression he...

Embodiment 2

[0023] Embodiment 2: The thin-walled container workpiece is a quadrilateral semi-open thin-walled container workpiece with unequal sides.

[0024] This embodiment is the turning of the joint surface of the oil pan part of the aluminum alloy material of the semi-opening thin-walled quadrilateral with unequal sides. Among them, the outer jaw assembly 1 is a four-jaw chuck, and the radial compression head assembly 2 is divided into four groups, and the gasket at the top of each group of compression head assembly 2 and each jaw position of the outer jaw assembly 1 are one by one. corresponds to a uniform distribution on the circumference.

[0025] The clamping method in this embodiment includes the following steps: when starting to process, the workpiece is first placed on the four-jaw chuck of the machine tool, the outer surface of the workpiece is in contact with the four-jaw chuck of the machine tool, and the tailstock of the machine tool is manipulated to drive the The movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com