Multi-story/high-rise fabricated steel structural prestressed supporting system capable of realizing rigid connection of joints

A technology of rigid connection and support system, applied in the direction of building structure and construction, can solve problems such as unfavorable structural stress, inability to realize rigid connection of nodes, etc., and achieve the effect of reducing project cost, shortening construction period and improving construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in detail below in conjunction with accompanying drawing:

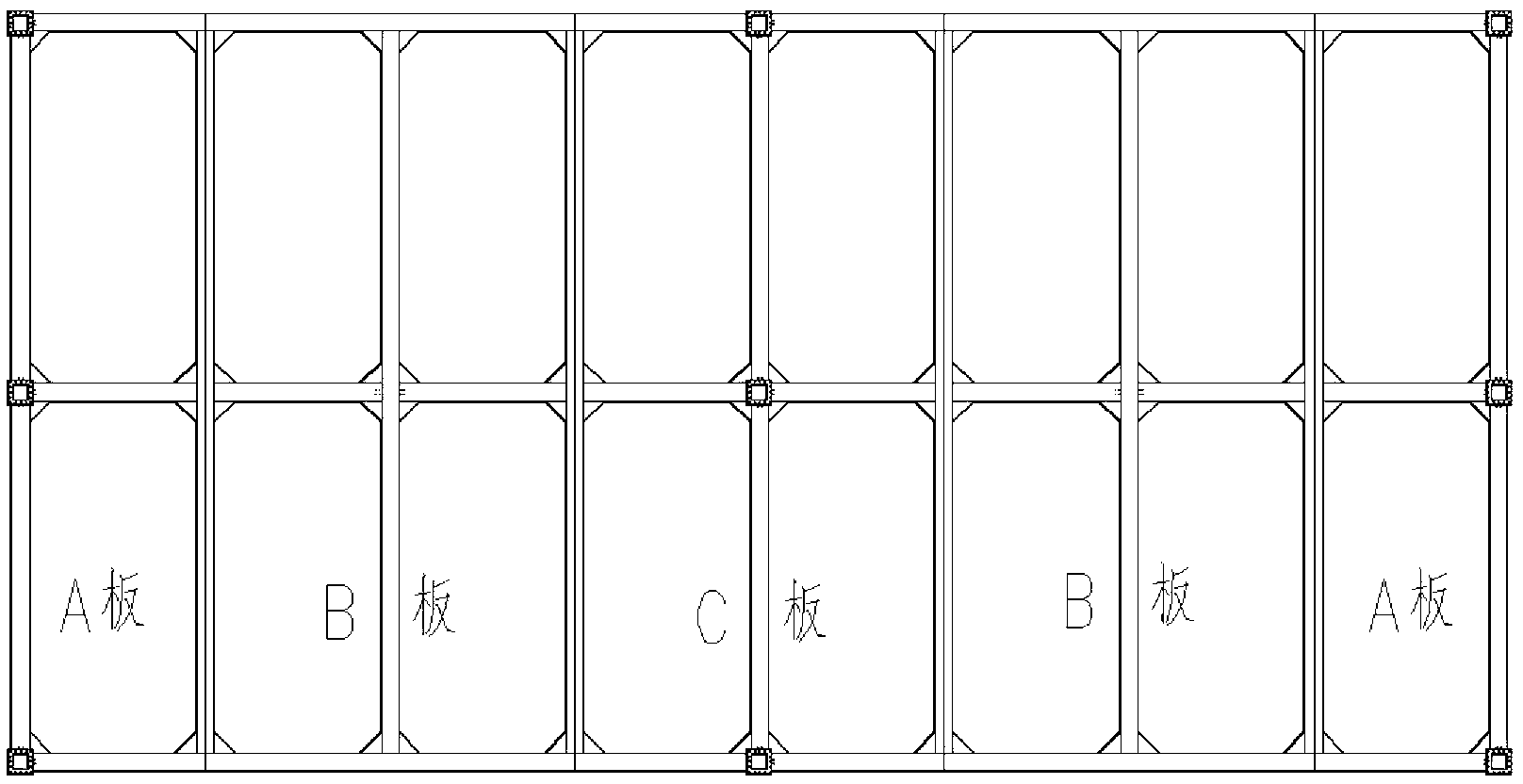

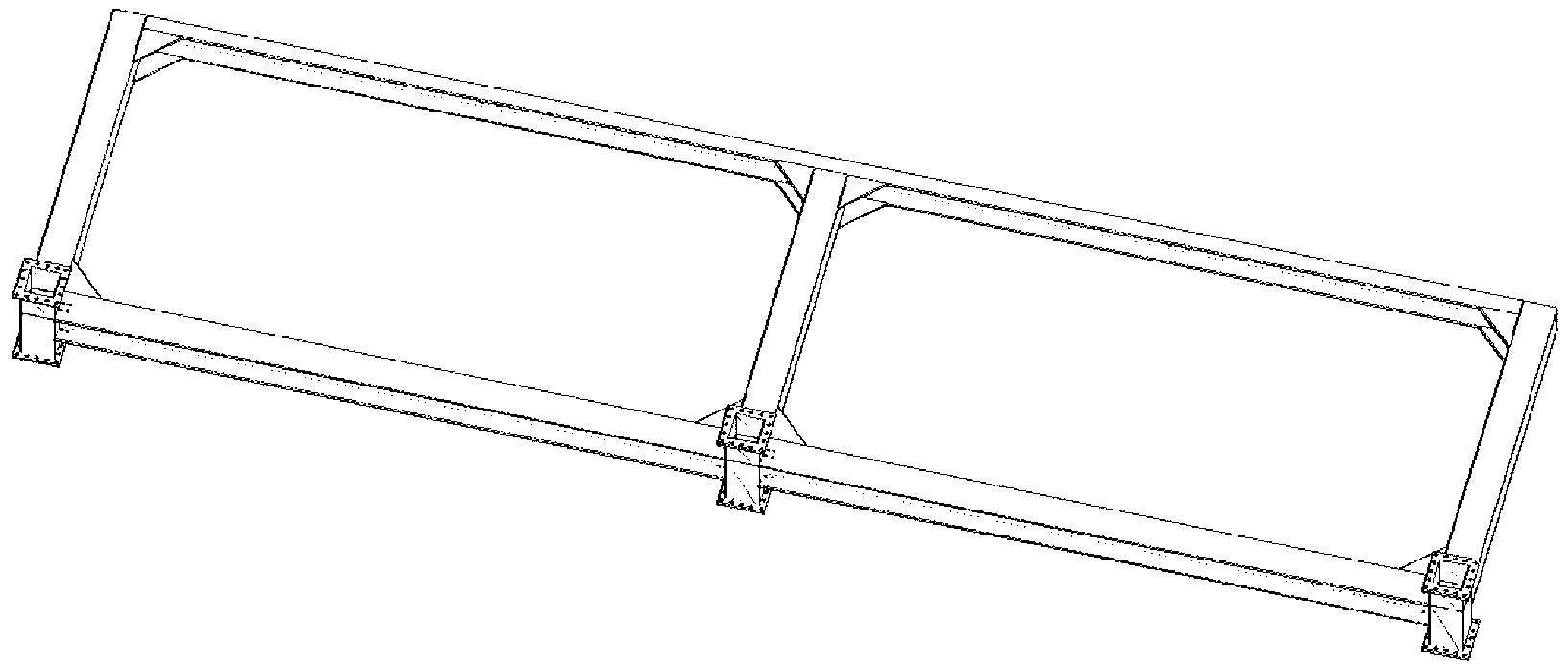

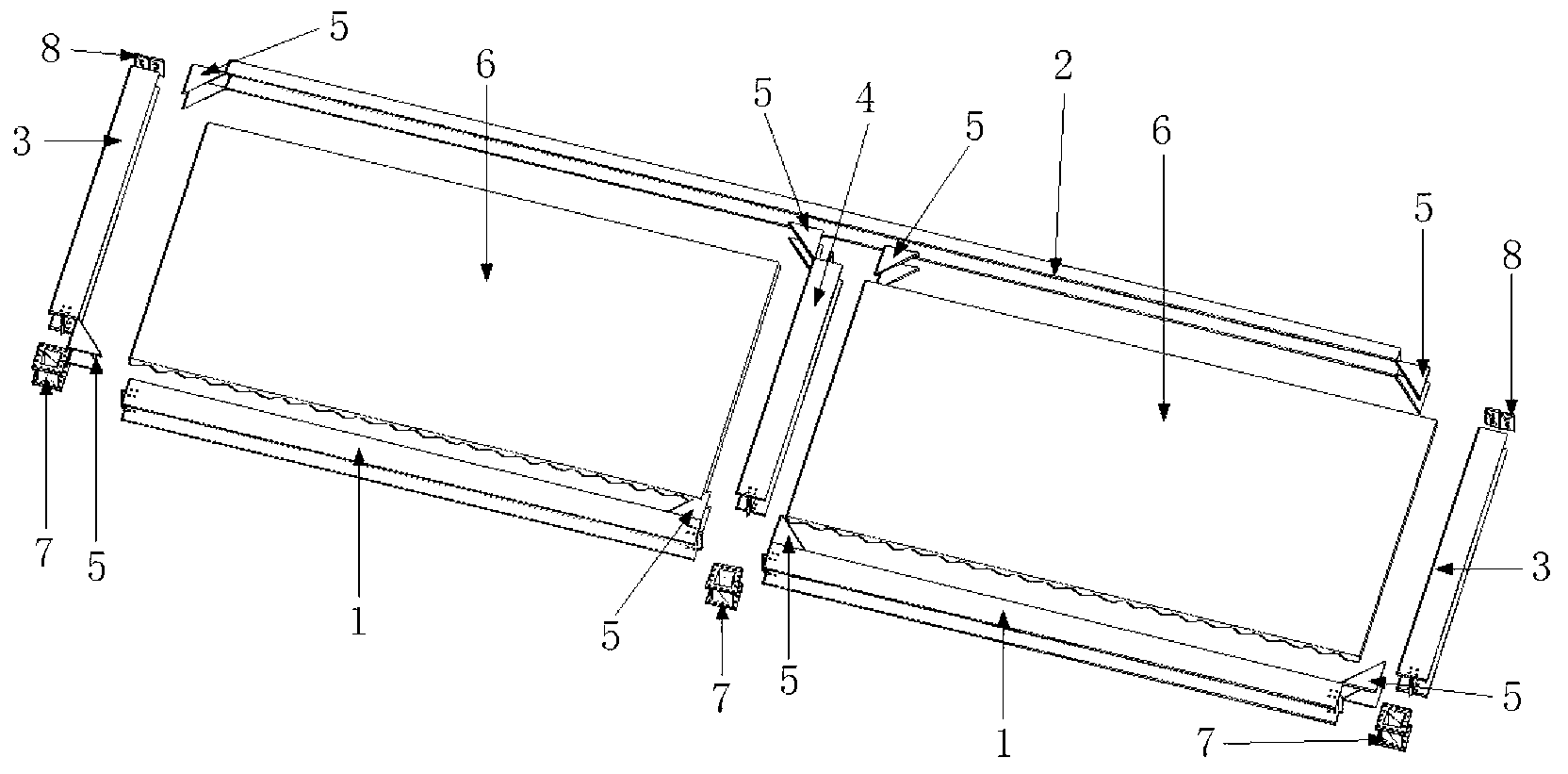

[0041] as attached Figure 1-19 As shown, in the multi-high-rise prefabricated steel structure prestressed support system that realizes node rigid connection proposed by the present invention, the multi-high-rise prefabricated steel structure prestressed support system consists of a prefabricated floor slab, a prefabricated flange column and a prefabricated prestressed support system. Stress oblique supports are assembled by bolts; the basic components of the prefabricated floor system are A plate, B plate and C plate, the two ends of the prefabricated floor system are A plate units, and the A plate unit is connected with B The unit connected to the other side of the B-plate unit is the C-plate unit, and the middle part of the floor system is alternately spliced with the B-plate unit and the C-plate unit.

[0042] as attached figure 2 And attached image 3 As shown, in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com