L-shaped steel concrete special-shaped column of supporting angle steel framework

A special-shaped column and concrete technology, which is applied in the direction of columns, pillars, pier columns, etc., can solve the problems of incomplete pouring of concrete in the protective layer, difficulty in vibrating, and narrow space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

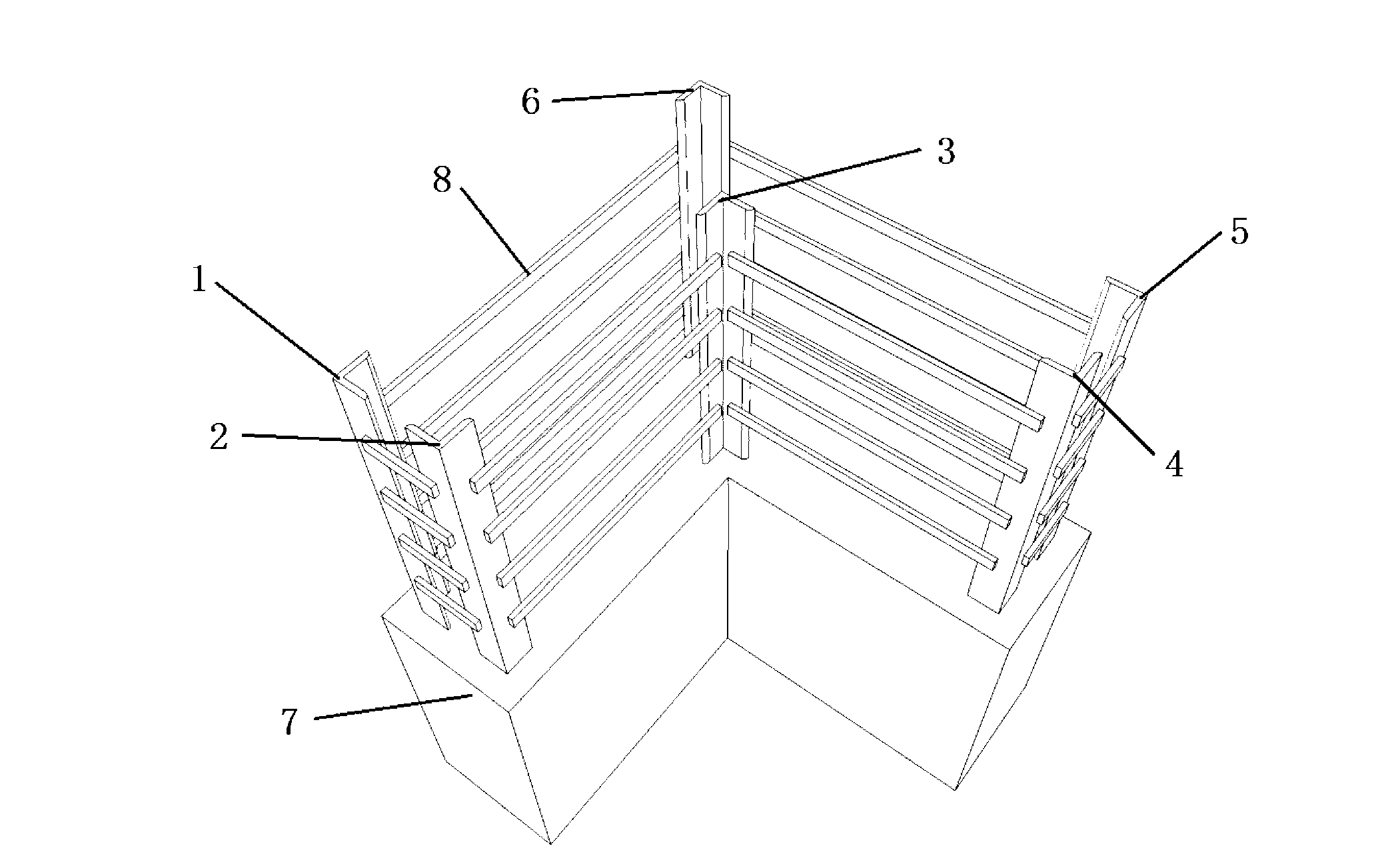

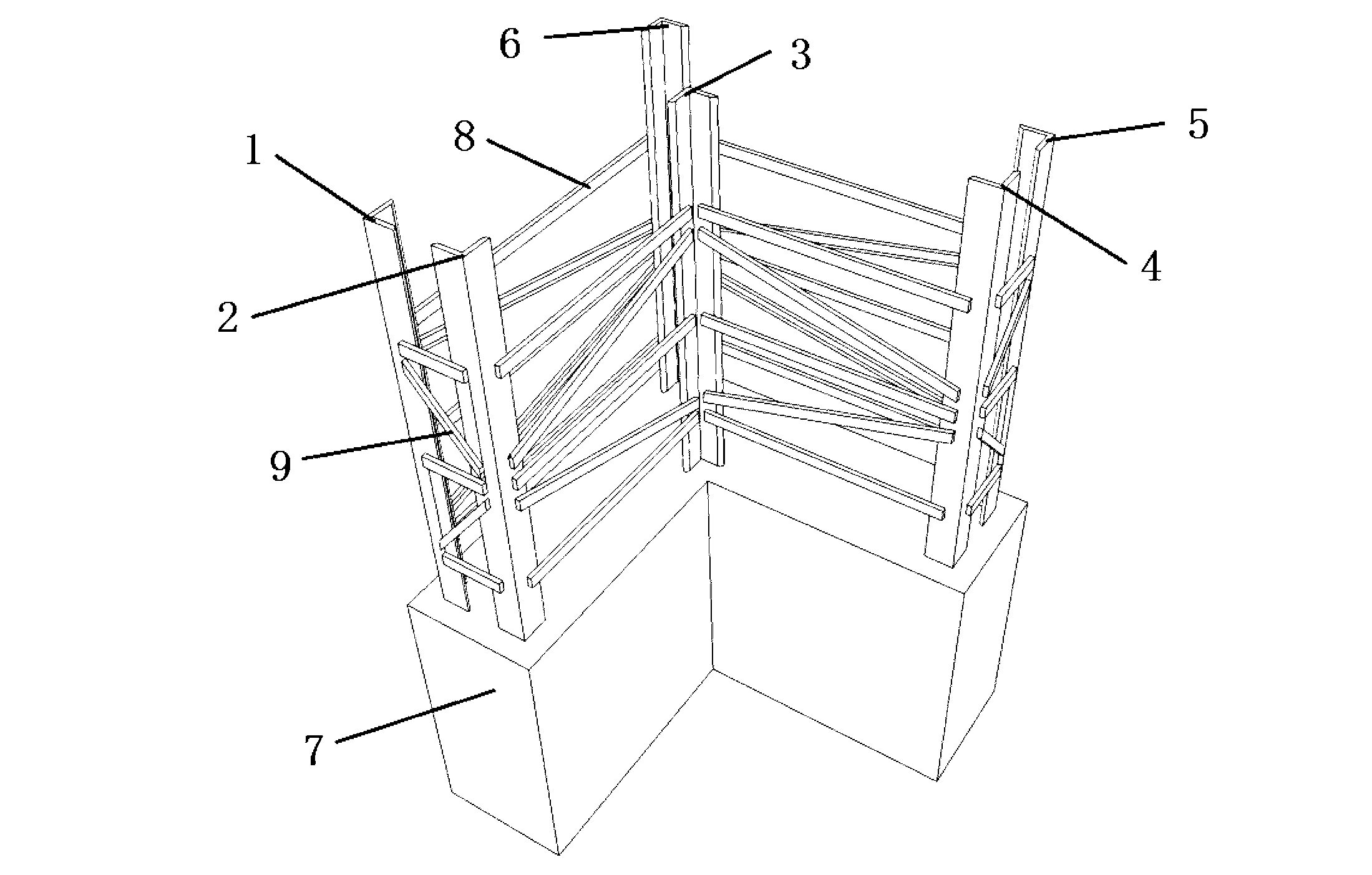

[0017] figure 1 It shows the first embodiment of the L-shaped steel concrete special-shaped column with angle steel frame in the present invention. The erection of the lattice angle steel frame is formed by welding all horizontal and transverse steel accessories. Among them, angle steel one 1, angle steel two 2, angle steel four 4, and angle steel five 5 are located at the end of each column limb of the L-shaped cross-section special-shaped column, and are arranged with the back of the angle steel limb facing outward, and the back surface of the limb is connected to the outer surface of the special-shaped column limb. The vertical distance between them is the thickness of the angle steel concrete protective layer; angle steel three 3 and angle steel six 6 are located at the intersection of the limbs of the L-shaped section special-shaped column, just at the corner of the section, and are set with the back of the limb facing inward. The location is the complex stress area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com