Preparation method of L-carnosine

A technology of carnosine and products, applied in the field of organic compound preparation, to achieve the effects of quality assurance, elimination of possibility, and elimination of hydrazine residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

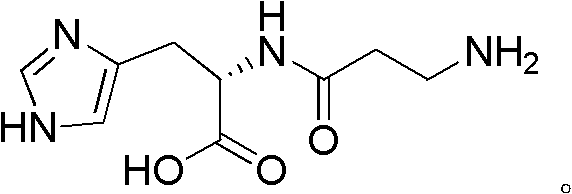

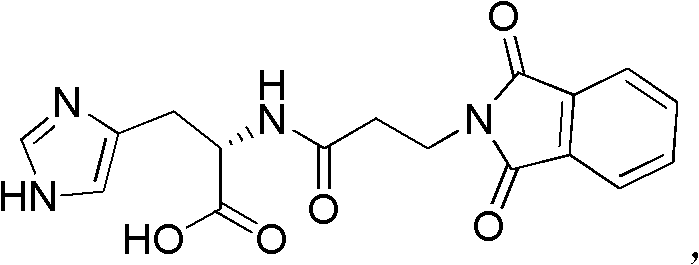

Image

Examples

Embodiment 1

[0023] Add 7.12 grams (2 mmol) of phthaloyl-L-carnosine and 80 mL of monomethylamine aqueous solution (30%, mass ratio) to a 250 mL reaction flask, and stir the mixed system at 80 ° C for 2 hours to stop the reaction and remove the solvent , adding 200 mL of absolute ethanol, stirring and heating to reflux, a white powdery solid was precipitated, filtered, washed with 20 mL of ether, and dried to obtain 3.87 g of carnosine product, yield: 88%. Hydrazine was not detected in the product.

Embodiment 2

[0025] Add 14.2 g (4 mmol) of phthaloyl-L-carnosine, 14 mL of methylamine ethanol solution (27-30%, mass ratio) and 350 mL of absolute ethanol into a 500 mL reaction flask, and heat to reflux for 1 hour. Filtrate hot, wash with 2×80 mL of absolute ethanol, wash with 2×80 mL of ether, and dry to obtain 8.02 g of carnosine product with a yield of 89%. Hydrazine was not detected in the product.

Embodiment 3

[0027] Add 3.56 g (1 mmol) of phthaloyl-L-carnosine, 30 mL of isopropanol and 4 mL of methylamine aqueous solution (30%, mass ratio) to a 100 mL reaction flask, heat to reflux for 1.5 h, and heat filter, 2×80 mL Wash with absolute ethanol, wash with 2×80 mL ether, and dry to obtain 1.68 g of carnosine product, with a yield of 74%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com