The method of prolonging the operation period of the circulating oil system at the top of the fractionating column

A technology of fractionating tower top circulation and operation cycle, applied in the direction of multi-stage series refining process treatment, etc., can solve the problems of increasing equipment investment cost, low operation flexibility, weakening the degree of corrosion, etc., achieving long-term efficient operation, eliminating Short operating cycles, eliminating the effect of reducing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

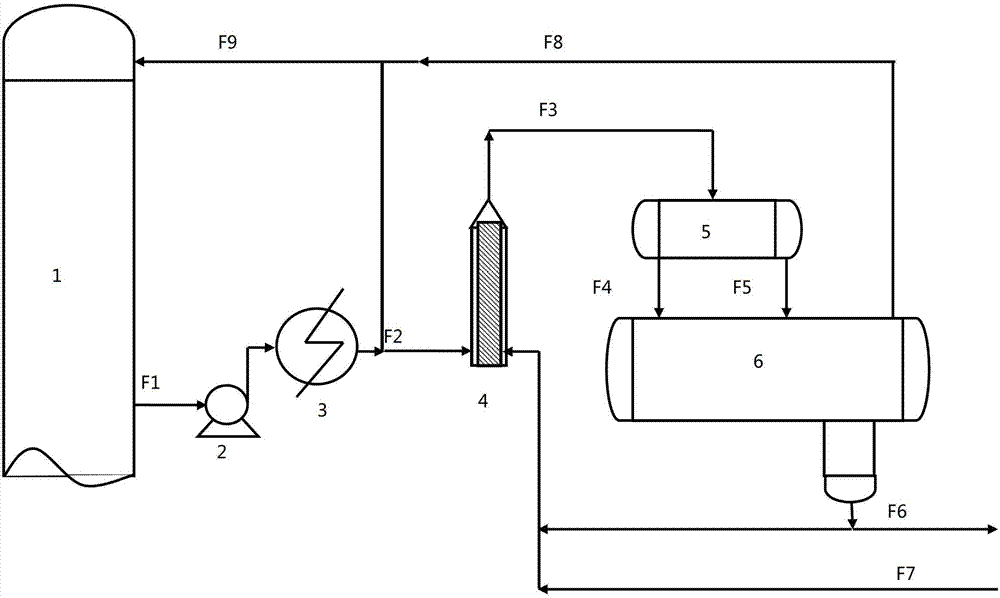

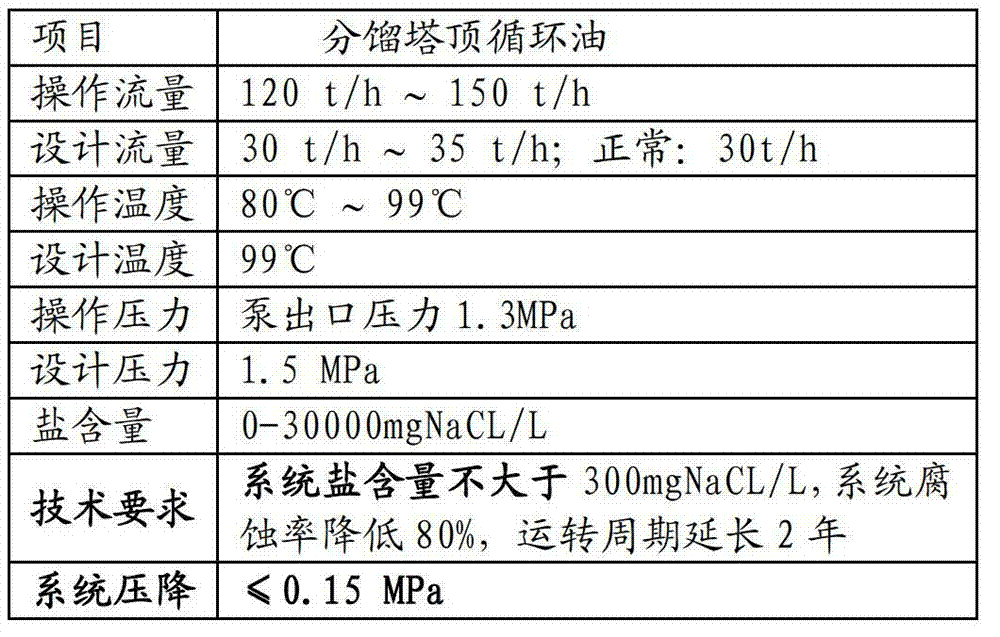

[0024] A petrochemical company's 1.4 million tons / year delayed coking fractionation overhead circulating oil system has a serious problem of salt accumulation, which affects the efficient and long-term operation of the system. Refer to Table 1 for the design parameters of the top cycle operation.

[0025] Table 1 Fractionation column cycle oil operating design parameters

[0026]

[0027] According to the pumping out of the circulating oil at the top of the fractionating tower, the temperature of returning to the tower, and the overall salt content level, it is proposed to use 1 / 4 of the circulating oil volume (about 30t / h) after heat exchange for water washing, extraction and separation. The brine or the acidic water at the top of the fractionation tower after deoiling in the device can achieve the purpose of maintaining the salt content of the entire top cycle at a low level. The specific implementation process is shown in Figure 1.

[0028] The circulating oil at the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com