Semisynthesis cutting fluid

A cutting fluid, semi-synthetic technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of large environmental pollution, low anti-corruption performance, short service life, etc., and achieve simple treatment, good anti-corruption performance, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

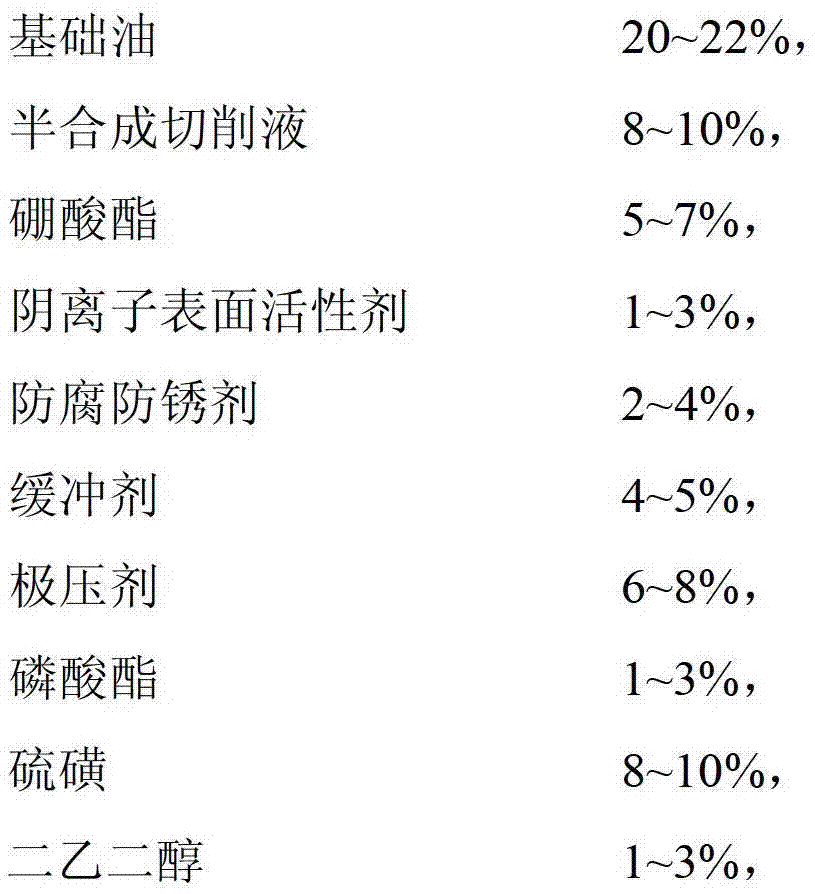

[0029] Semi-synthetic cutting fluid contains the following components in weight percentage:

[0030]

[0031]

[0032] Put the above-mentioned substances except deionized water and silicone defoamer into the reaction kettle, stir and react at 30°C for 40min, then add deionized water and silicone defoamer, stir and react at 40°C for 40min to obtain half Synthetic cutting fluid. The semi-synthetic cutting fluid of the invention is environmentally friendly, has a good protection effect on human body and equipment, is easy to treat the waste liquid after use, and has good anti-corruption performance.

Embodiment 2

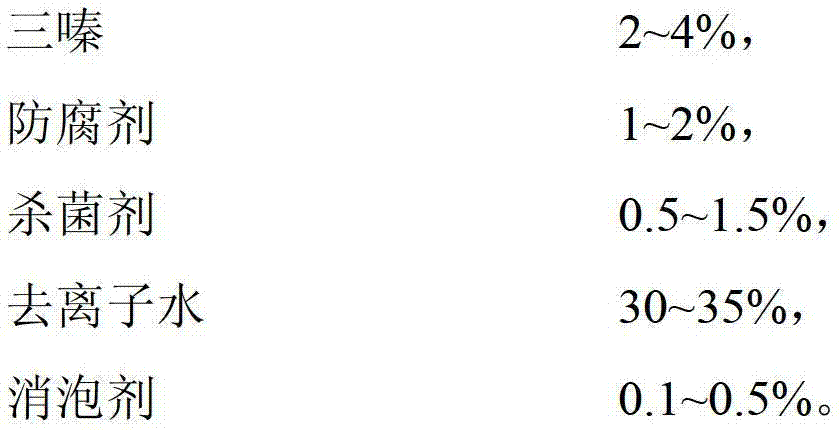

[0034] Semi-synthetic cutting fluid contains the following components in weight percentage:

[0035]

[0036] Put the above-mentioned substances except deionized water and silicone defoamer into the reaction kettle, stir and react at 40°C for 40min, then add deionized water and silicone defoamer, stir and react at 35°C for 40min to obtain half Synthetic cutting fluid.

Embodiment 3

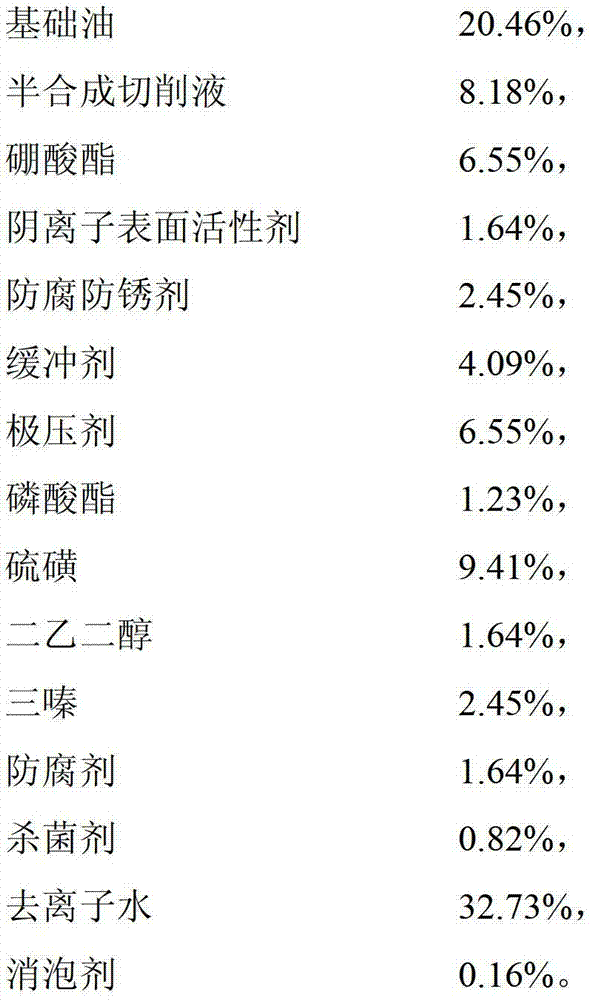

[0038] Semi-synthetic cutting fluid contains the following components in weight percentage:

[0039]

[0040]

[0041] Put the above-mentioned substances except deionized water and silicone defoamer into the reaction kettle, stir and react at 35°C for 40min, then add deionized water and silicone defoamer, stir and react at 30°C for 40min to obtain half Synthetic cutting fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com