Rotary gas-solid heat exchange device utilizing waste slag heat and heat exchange method

A heat exchange device and a rotary technology, which is applied in the field of blast furnace slag heat exchange, can solve the problems of large water consumption and harmful gas pollution, and achieve the effects of energy cost saving, environmental protection, and energy cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

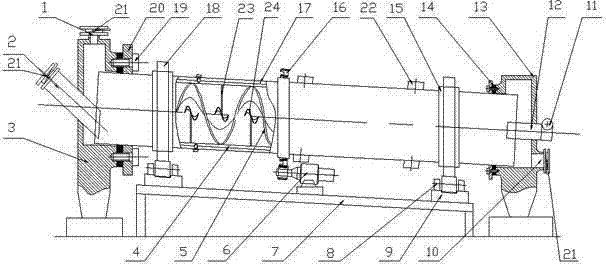

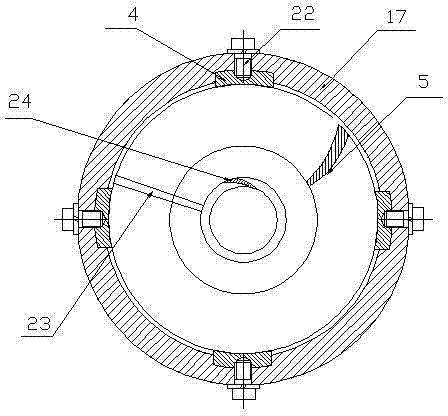

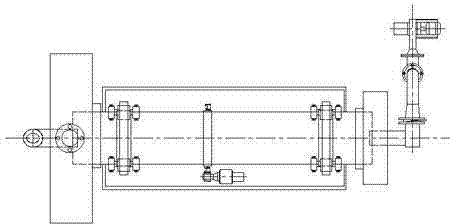

[0036] refer to Figure 1-4 As shown, the rotary heat exchange device described in this embodiment uses high-temperature blast furnace slag particles to exchange heat with gas, and the rotary heat exchange device includes a heat exchange cylinder 17 fixedly supported by a cylinder bracket 7 for controlling The rotation control motor 6 and the cooling fan 27 for the rotation of the heat exchange cylinder. The heat exchange cylinder 17 is provided with a spiral track composed of spiral blades 5 and a spiral blade fixing bracket 4. The heat exchange cylinder 17 is provided with Four grooves are used to fix the helical blade fixing bracket 4, and the helical blade fixing bracket 4 is welded with a helical blade 5 to control the operation mode and direction of the heat exchange material. The helical blade fixing bracket 4 and the heat exchange cylinder 17 are provided with bolts Holes, every three have twelve holes altogether to screw on the helical blade fixing bolt 22 and fix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com