Production well resistivity logging device

A technology for resistivity logging and production wells, applied in boreholes/well components, earthwork drilling and production, etc., can solve problems such as difficult logging, low work efficiency, and failure to consider casing degaussing, and improve logging Efficiency, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

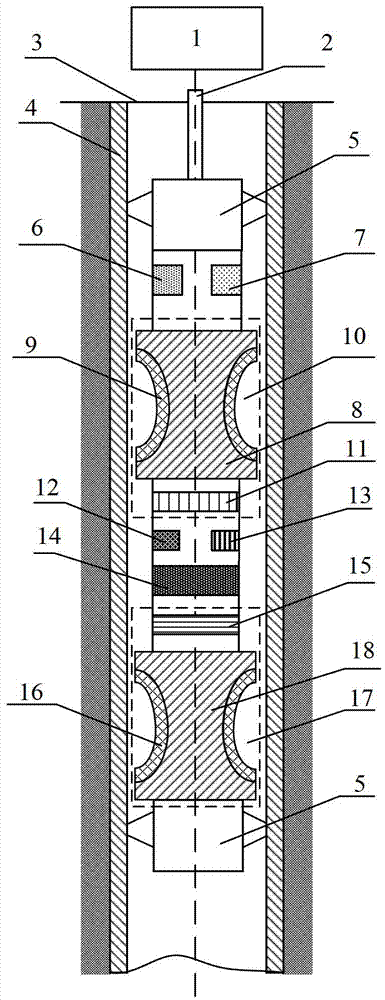

[0023] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] refer to figure 1 , a production well resistivity logging device, comprising a surface system 1, the surface system 1 is connected to the upper part of a centralizer 5 of a downhole logging device 3 through a cable 2, and the downhole logging device 3 includes a centralizer 5, an upper polarization power supply 6. The lower polarization power supply 7, the upper polarization device 10, the transmission control unit 12, the reception processing unit 13, the magnetic field detection unit 14, and the lower polarization device 17; the centralizer 5 is located at both ends of the downhole logging device 3 and Contact with the casing 4 ensures that the instrument is in the center position in the well; the upper polarization device 10 is in the center position in the wellbore, and the upper polarization frame 8 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com