Detecting method, detecting device and calculating method of three-phase fluid proportions and flow

A flow test device and fluid ratio technology, which is applied in the volume flow ratio measurement, measurement device, liquid/fluid solid measurement, etc., can solve the problems of large volume of flowmeter and no unified test evaluation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

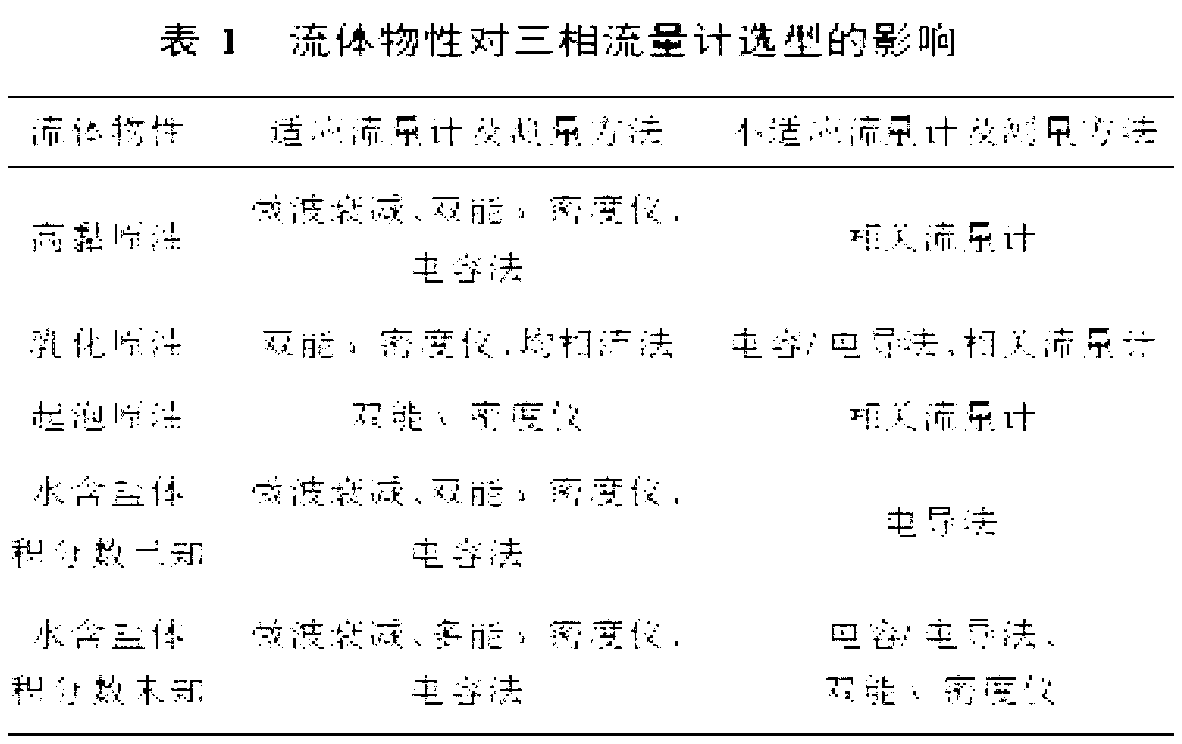

[0062] A method for testing the ratio and flow of three-phase fluids of the present invention proposes the theory of using continuous pressure measurement to measure the ratio and flow of three-phase fluids online, and adopts a completely different idea and brand-new design concept; in complex fluids Under certain circumstances, the stress test results are more representative and more reliable than other existing test methods.

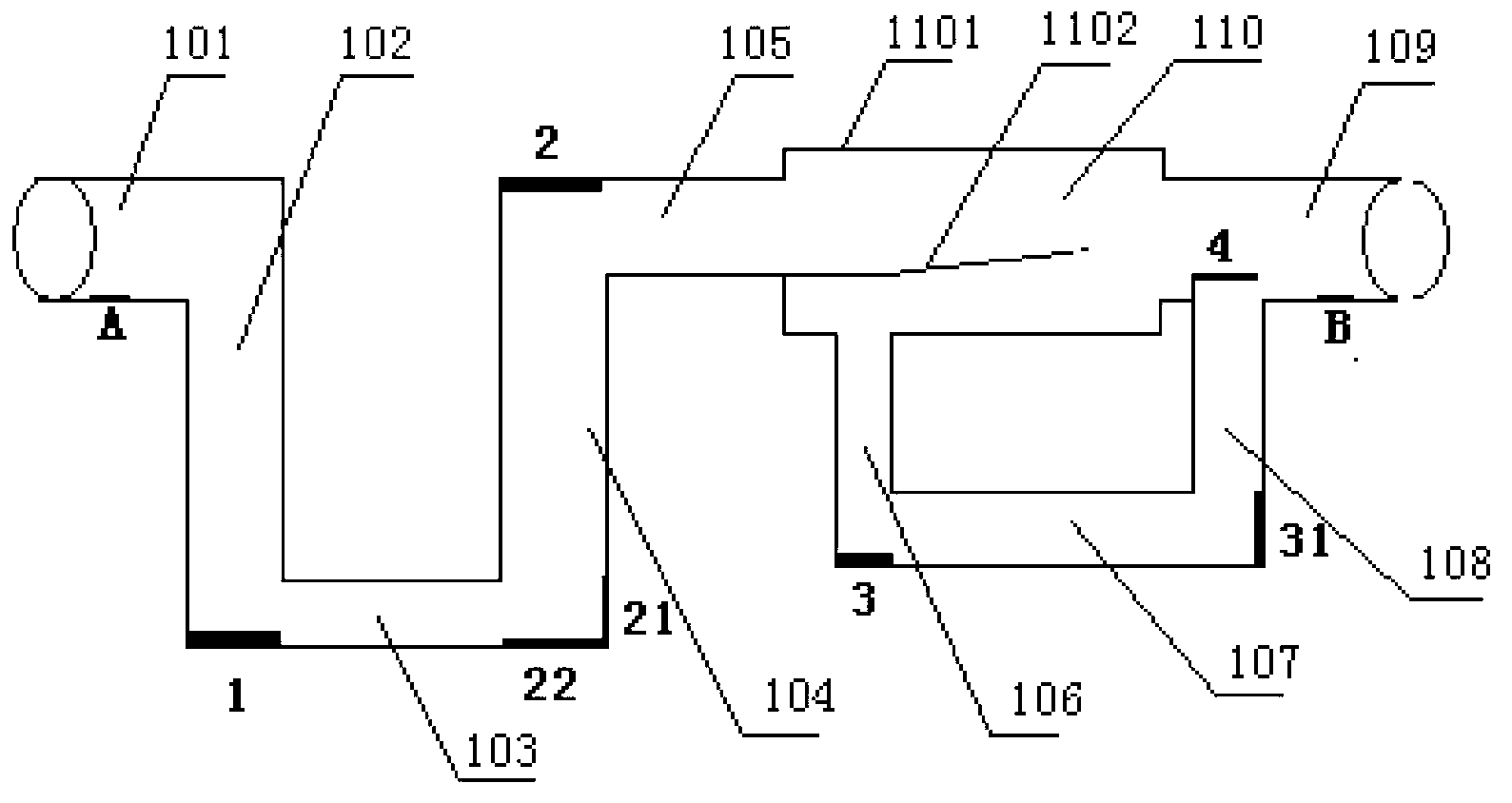

[0063] Based on the above theoretical method, the present invention provides a three-phase fluid ratio and flow testing device, which can simultaneously test the three-phase fluid ratio and overall volume flow. The schematic diagram of the test device is shown in figure 1 As shown, it includes pipelines and seven pressure sensors 1 , 21 , 22 , 2 , 3 , 31 , and 4 .

[0064] The first, third, fifth, seventh, and ninth pipelines 101, 103, 105, 107, and 109 are all horizontally arranged pipelines, and the second, fourth, sixth, and eighth pipelines 102, 1...

Embodiment 2

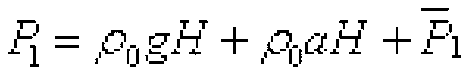

[0072] Utilize the test device in embodiment 1 to measure and calculate and can draw the ratio of three-phase fluid and the volumetric flow rate of three-phase fluid, refer to simultaneously figure 1 , Section 1-22-21-2 of the pipeline flows through the overall three-phase flow, and after passing through the expansion diverter 110 and the splitter plate 1102, the pipeline of section 3-31-4 flows through the two phases of oil and water. Due to diameter expansion, diversion, and swirling flow, it is difficult for gas to flow into the 3-31-4 section pipeline. A and B are the temperature sensors at the input and output ends of the flowmeter. The temperature of each section of the flowmeter can be calculated from the temperature gradient, and the density changes of the three-phase fluids can be determined by temperature changes. The density-temperature curves of each phase fluid are given by referring to the density-temperature curve. current density. with P 1 ,P 2 The average v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com