Measuring method of catalytic cracking slurry solid content

A technology of catalytic cracking oil slurry and measurement method, which is applied in the field of determination of solid content (toluene insoluble matter) of catalytic cracking oil slurry, can solve the problems of reduced stability and precision, small particle size, and low content of solid particles, and achieves The loss of solid phase is reduced, the stability is increased, and the effect of low precision is solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

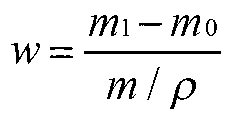

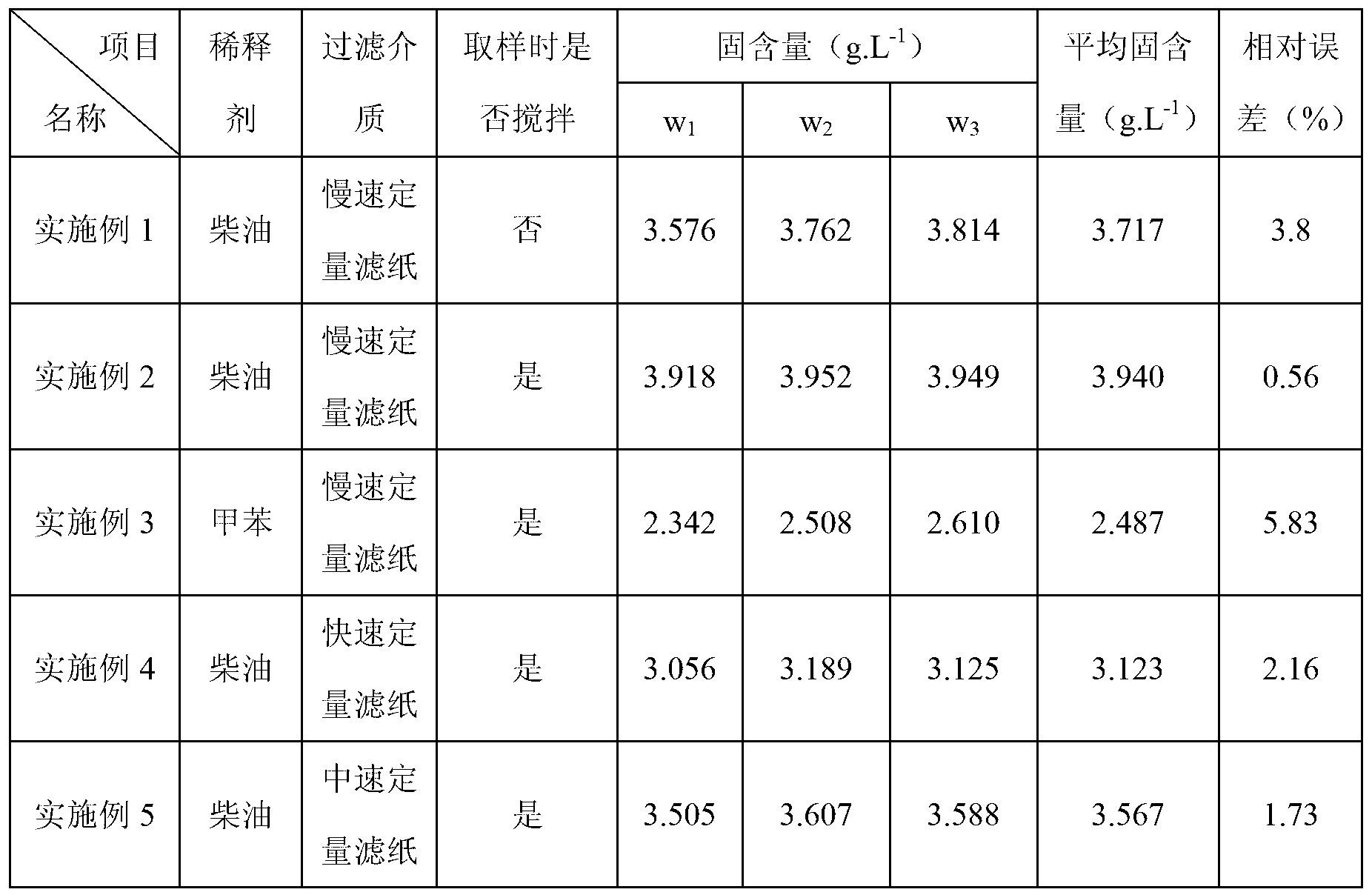

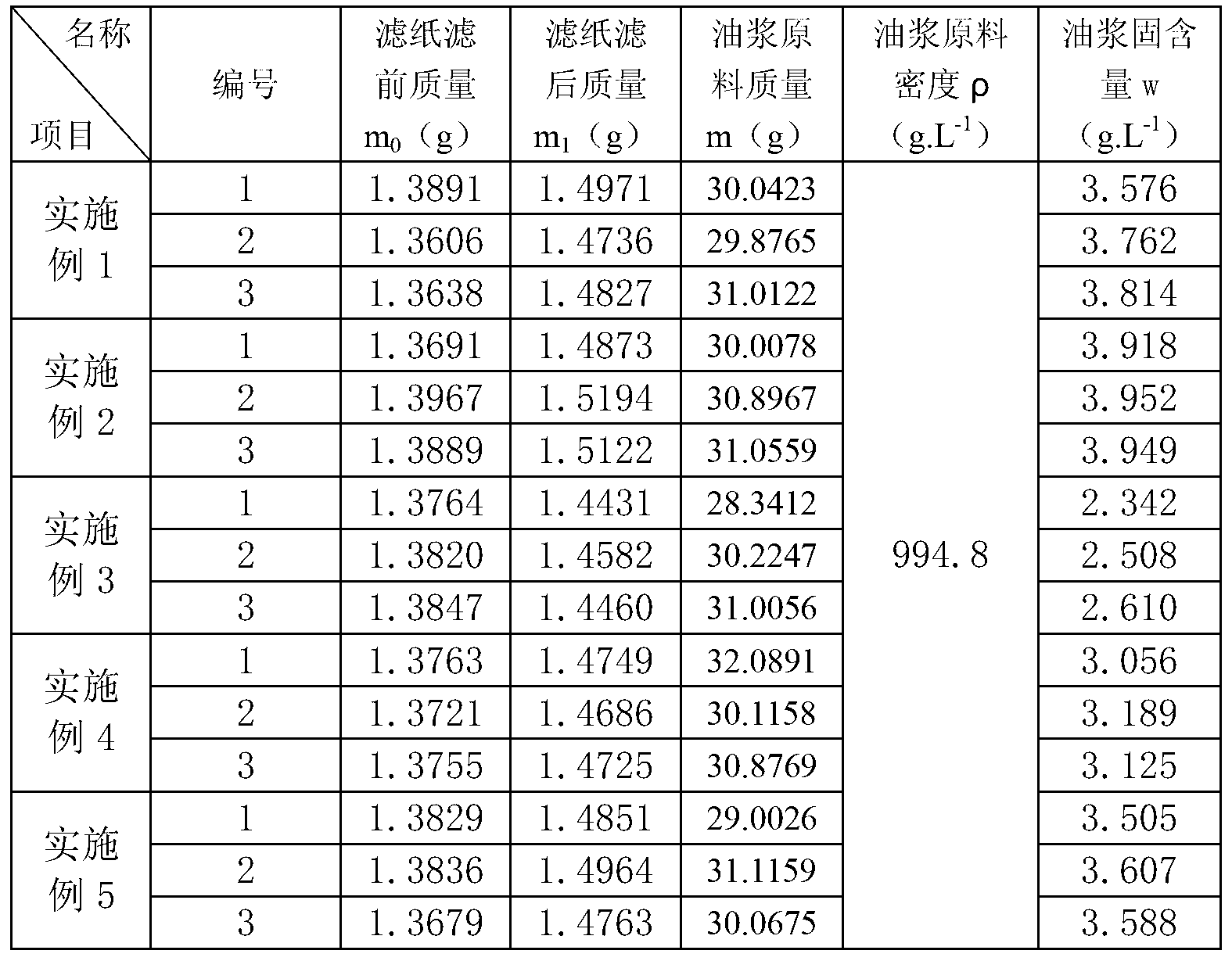

[0030] Without any treatment to the oil slurry in the 500ml beaker, take 30g of oil slurry into three 250ml beakers, dilute with 160ml diesel oil, and filter with slow quantitative filter paper to measure the solid content.

[0031] The operating conditions and test results are shown in Table 1, and the test data required to calculate the solid content by the formula are shown in Table 2. From the measurement results, with the deepening of the sampling position, the solid content of the oil slurry increases continuously. According to the 3.576g / L in the beaker 1 and the 3.814g / L in the beaker 3, the oil slurry has obvious natural settlement. And the relative error is large.

Embodiment 2

[0033] The oil slurry in the 500ml beaker was stirred at a constant temperature of 50-60°C for more than 10 minutes, and then the steps were the same as in Example 1, and the solid content of the oil slurry in the three beakers was measured.

[0034] The operating conditions and test results are shown in Table 1, and the test data required to calculate the solid content by the formula are shown in Table 2. From the results of solid content determination, the solid phase distribution of the oil slurry after stirring is relatively uniform, with an average value of 3.940g / L, which is closer to the carbonization burning value, and the average error is small, only 0.56%.

Embodiment 3

[0036] The steps were the same as those in Example 2, the diluent was the same volume of analytically pure toluene, and then the solid content of the oil slurry in different beakers was measured.

[0037] The operating conditions and test results are shown in Table 1, and the test data required to calculate the solid content by the formula are shown in Table 2. From the solid content determination results, it can be seen that the average solid content of the oil slurry is 2.487g / L, which is significantly lower than the carbonization and ignition value of the solid content of the oil slurry, and the maximum relative error is as high as 5.83%, and the stability is poor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com