Laser gas detection method with automatic linearity correction function

A linear correction, laser gas technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of increasing the workload of the staff, changing the performance of the detection device, hidden safety hazards, etc., to extend the manual correction period, ensure stability, and realize automatic The effect of correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

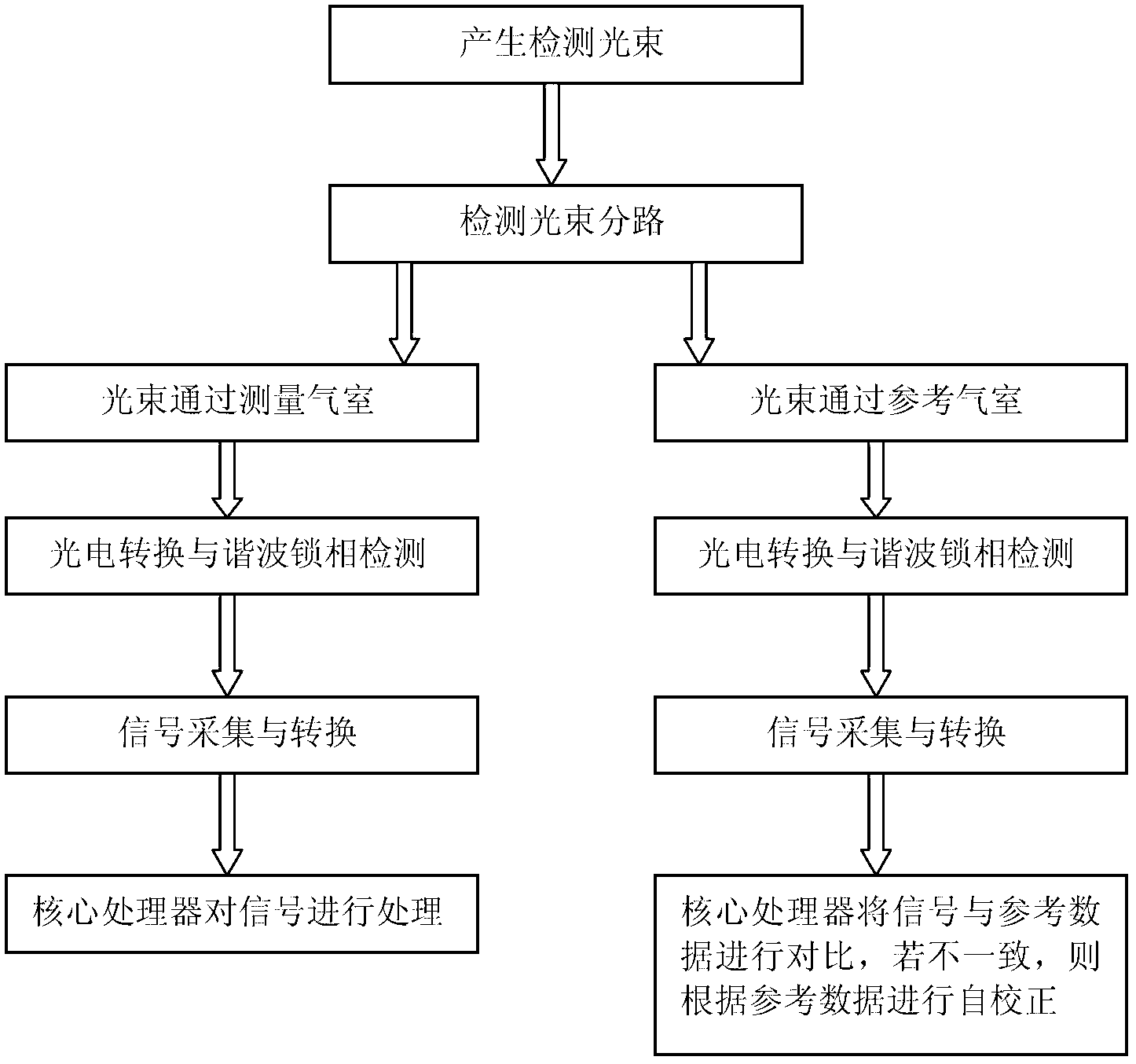

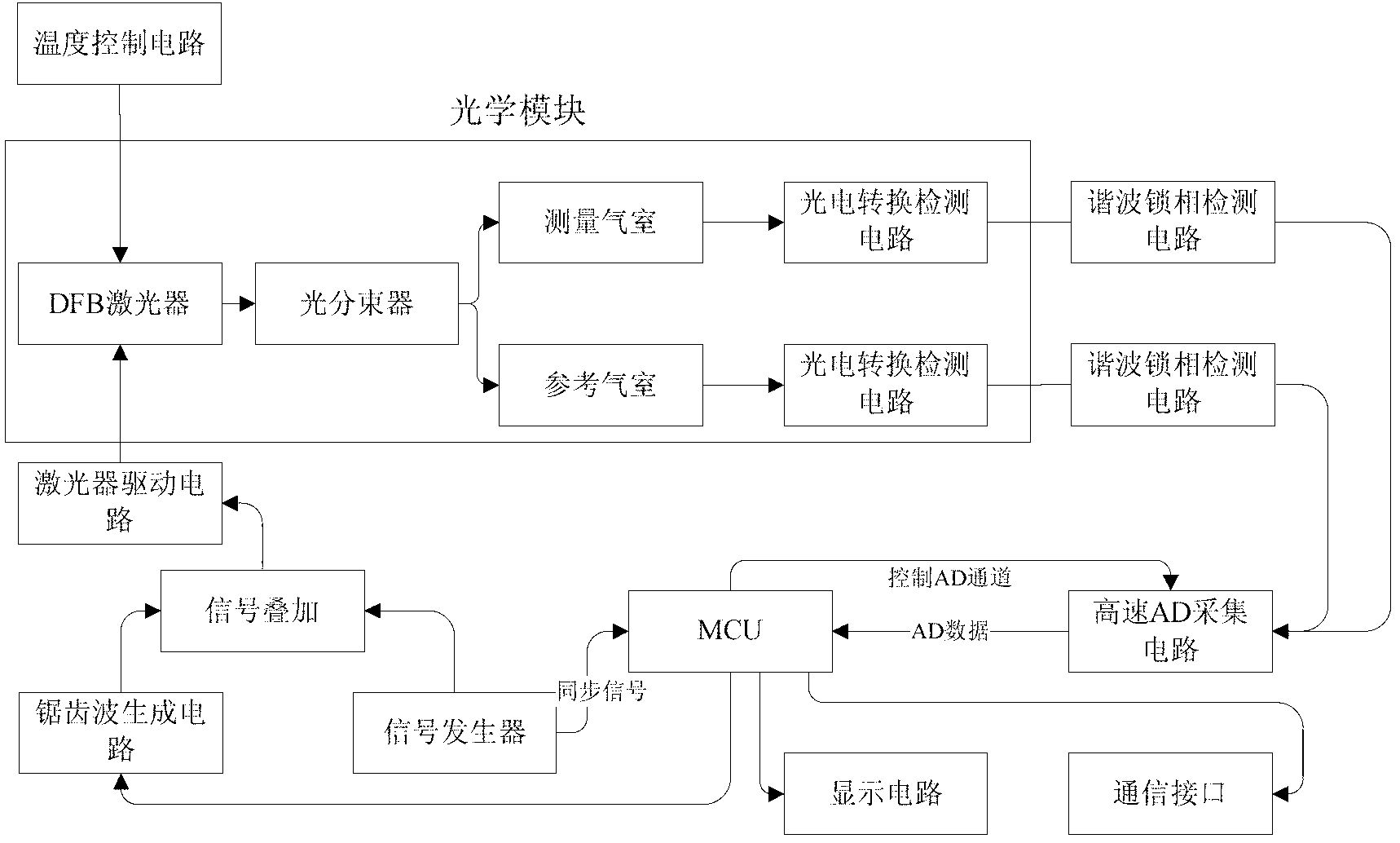

[0018] figure 1 As the flow chart of this detection method, as shown in the figure, the laser gas detection method with automatic linear correction function according to the present invention includes the following steps: Step 1: use a laser to generate a detection light source, and the monochromatic beam output by the laser is used as the detection beam ; Step 2: Split the detection beam in step 1. In this embodiment, a fiber optic splitter is used to divide the detection beam into two paths; Measuring the gas chamber, send another beam into the reference gas chamber with known concentration gas, and record the known concentration value and the laser center wavelength position after the first linear calibration as reference data; Step 4: From the measuring gas The two beams from the reference chamber and the reference gas chamber are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com