Method for producing liquid crystal panel

A liquid crystal panel and backside technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of color filter substrate and array substrate dislocation, affect the quality of liquid crystal panel surface, and reduce the opening area, so as to reduce light leakage and reduce Streaming time, the effect of reducing the cost of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

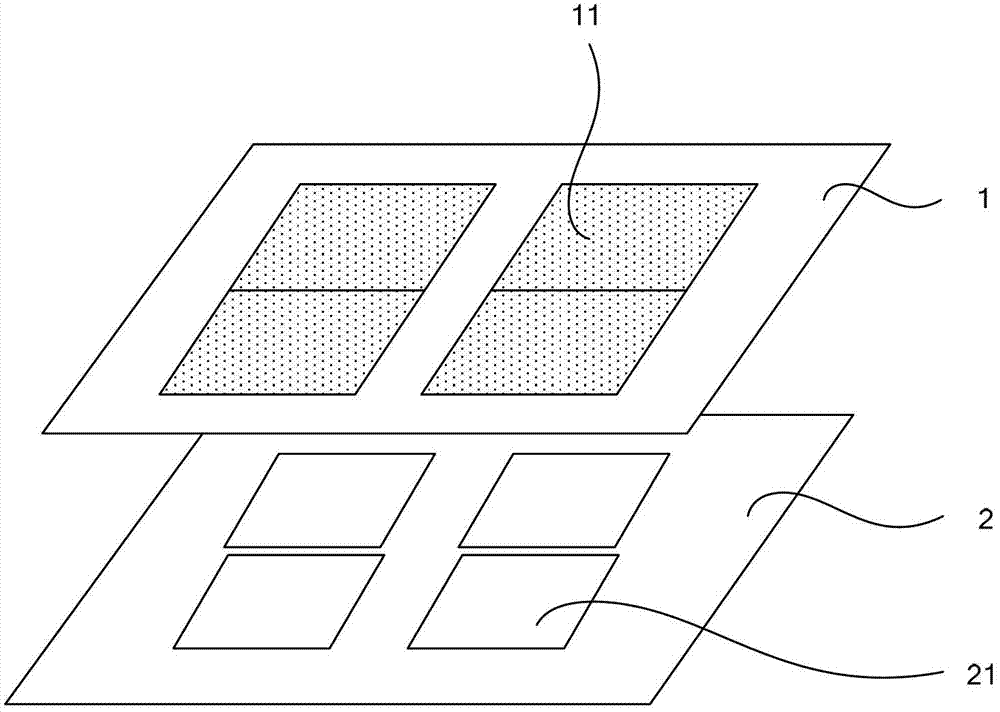

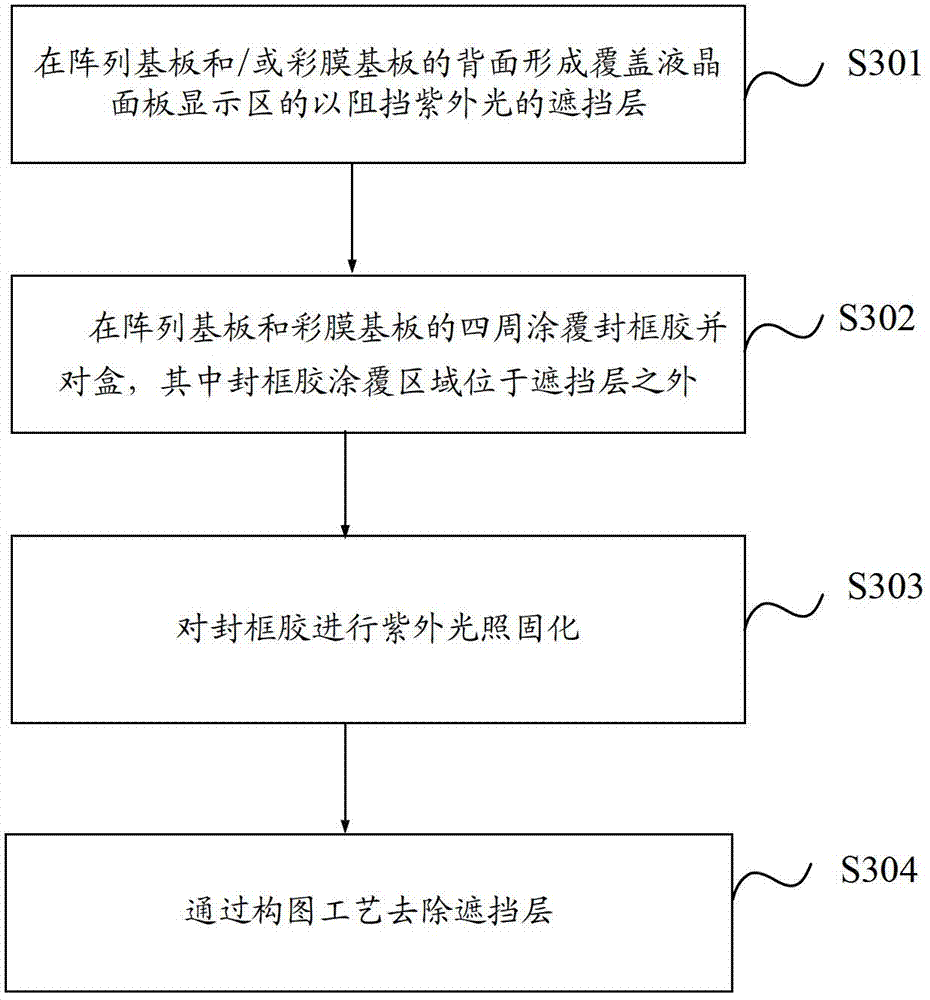

[0037] Such as figure 1 with figure 2 shown, where: figure 1 The liquid crystal panel provided for the present invention is a structural schematic diagram before box alignment; figure 2 It is a flow chart for preparing a liquid crystal panel provided by the present invention. An embodiment of the present invention provides a method for preparing a liquid crystal panel, including:

[0038] Step 301: forming a shielding layer 11 covering the display area 21 of the liquid crystal panel on the back of the array substrate 1 and / or the color filter substrate 2 to block ultraviolet light;

[0039] Step 302: apply frame sealant around the array substrate 1 and the color filter substrate 2 and align the boxes, wherein the coated area of the frame sealant is located outside the shielding layer 11;

[0040] Step 303: curing the frame sealant with ultraviolet light;

[0041] Step 304: removing the shielding layer 11 through a patterning process.

[0042] In the preparation metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com