Paid recovery device for waste batteries

A waste battery and recycling device technology, applied in the direction of starting with a returnable container, can solve the problems of low recycling rate, low compensation, and inconvenient compensation of waste batteries, and achieve the effect of convenient operation, improved enthusiasm, and effective recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

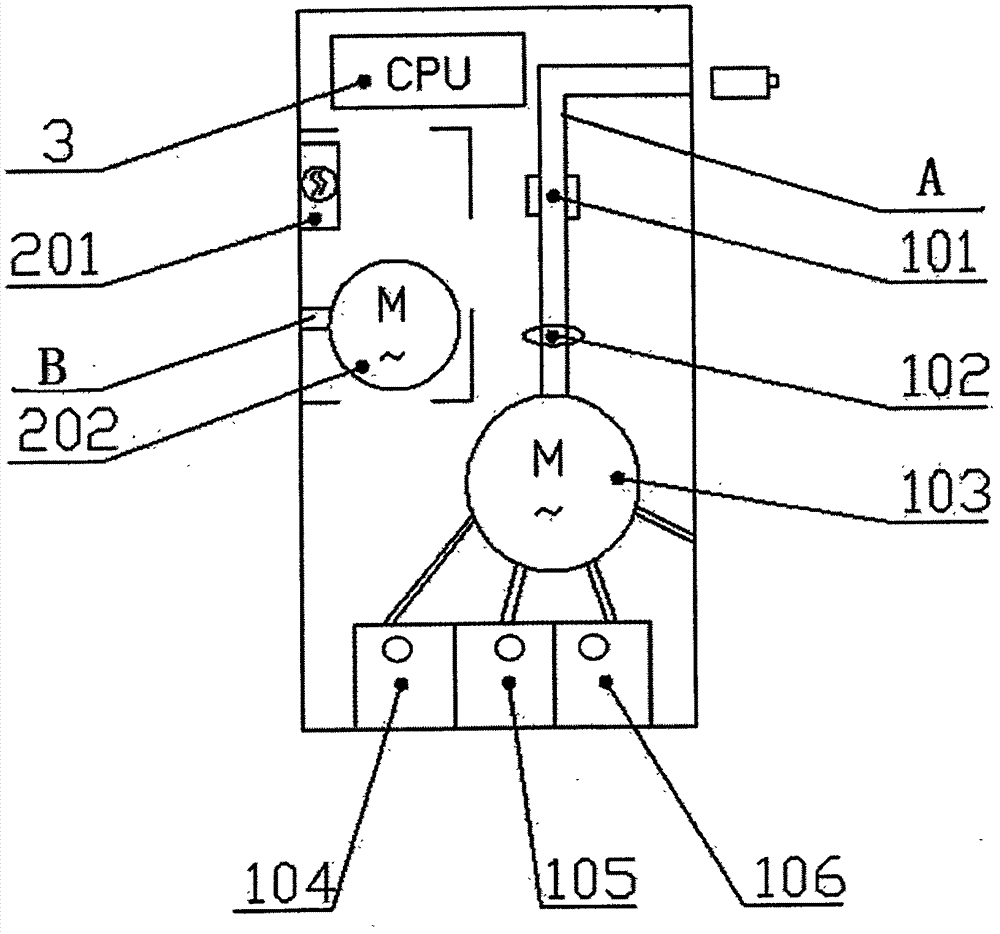

[0016] refer to figure 1 , The paid recycling device for waste batteries in this embodiment includes three parts: a waste battery recovery part, a new battery discharge part and a calculation control part. The waste battery recycling part includes: the waste battery inlet and the battery recycling box A104, the battery recycling box B105, and the battery recycling box C106, which are connected by a pipe A, and a waste battery detection device is installed on the pipe A. The calculation control part includes: AVR ATmega16L single-chip microcomputer 3, which is connected with the waste battery detection device, stepper motor B and driver 202, coin receiving and identification device 201, and the display screen through signals. The new battery spitting part includes: a stepper motor B and a driver 202 to drive the pipeline B connecting the new battery s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com